24 Foot Sailing Trimaran

Introduction: 24 Foot Sailing Trimaran

Indonesian style, built out of recycled stuff. Here we are busting out through the surf in 30mph winds at Stinson Beach California on the maiden voyage. The boat works great! There are no swimmers or surfers out because of the rough conditions. The kids are on the beach making forts out of their boogieboards instead of surfing. Specifications: Hull Length 24 ft at deck Hull 22" wide amidships at deck, 18" wide inside hull (there's a wide lip at deck) Hull 24" deep amidsnips. The hull round bottom is a semicircular arc of 8.25" radius. Hull rocker is about 4" measured from points 16' apart. Outrigger crossbeams are 14' 7" long 3.5"x2.5" fir beams tapering to 3x2.25" at ends The outrigger floats are 4.5" diameter, 19 feet long with foam plugs in ends. ~134lbs buoyant. The plugs in the front of the floats are shaped into a nose that protrudes 6.5" more. 1.5" diameter stainless steel tubing connects the crossbeams and floats. The Sail is an 8 sq. meter crabclaw / leg-o-mutton sail on 14ft. windsurfer masts. The mast is supported by three stainless steel cable stays. Total cost of materials was $200 or less. The outrigger floats are fiberglass chemical pipes full of empty plastic soda bottles. The main hull is made from a pair of old 16' catamaran hulls cutoff and glassed end-to-end. Junked catamaran hulls are easy to get. If you can't find a free hull, build a hull like the Kenya Canoe but bigger. Use scavenged plywood from crates if you want it free. The wood for the crossbeams came from a big pallet, with the nails and crossboards pulled off. Then I scarfed them together for extra length. The sail is blue tarp on windsurfer mast spars. Great action photos by kenny

Step 1: Beaching After the Maiden Voyage

Star , Damon and myself rode the boat in on the back of a big wave, just like the Malibu Outrigger manual recommends. Then we carry the boat up the beach. The sail helps us and we scamper up the beach and get clear of the break zone before the next wave hits. What a great boat. Unlike trials of previous boats in Mexico and Kenya which got badly damaged by surf landings, this boat is fine. It helps that there's a lot of wind and the boat is faster than the waves.

Step 2: Cartopping

Here it is on top of the ugly truckling. It assembles quickly without tools. The main hull is the heaviest part, about 90 lbs. It takes two people to lift it onto the roof rack because it's so big. The other parts are a lot lighter and one person can handle them. 4 or 5 people can ride in the cab of my truck. The boat could carry that many also, so it's a good match. We could only get three people to volunteer for the maiden voyage because the conditions were so rough, but there was room for more.

Step 3: Or on a Trailer

To launch it from a trailer, you drive to the boat ramp, assemble the boat while still on the trailer, then launch and land it in the usual way.

Step 4: Inspiration

I once tried to sail to Cuba in an outrigger canoe. There were some problems. When I was almost to Havana my rudder broke so I couldn't sail, the current carried me away, I was caught in a storm, etc. etc. I spent a lot of time trying to not to die and hallucinating from exhaustion. I also spent a lot of time thinking about the perfect hull shape for a sailing canoe. In the following year I traveled to Indonesia and Papua. I learned a lot by gaping at and measuring sailing canoes there. Here are some Makassarese (Sulawesi) canoes I saw in Jayapura Harbor, Papua. In severely technical terms, here's what I was looking for in a hull: 1) High prismatic coefficient (fat ends) 2) Round bottom 3) Straight sides in the middle 4) Just the right amount of rocker. Curved like a banana. 5) A beam to length ratio of around 12:1

Step 5: Cut and Paste Catamaran Hulls Together End-to-end

I found a pair of 16' catamaran hulls for sale on craigslist that were exactly what I was looking for. By no coincidence, they were designed and built by Karl Westbroek, an engineer from Malang, Java, Indonesia. They were a nice bright yellow that emphasized their banana-like shape. Hence Karl's original name for his catamaran, "Bananas". I wanted my hull to be pointy at both ends. These hulls had square transoms at the stern. So I had to cut off the sterns and butt up the pointy ends to make my hull. To figure out the right place to cut them I slid a piece of paper over the hulls to find a special transverse curve called the "Geodesic". That's the shortest path between two points on opposite sides of the hull. I cut the hulls, butted them up, and checked to make sure the keel and sides met at a reasonably fair curve.

Step 6: Thinning the Edge

Before we can start glassing, we need to grind down the existing fiberglass so it's a smooth transition. Michael Kearney helps me out by grinding the edge thin on the inside of the joint.

Step 7: Jigging It Up

Next we clamped and screwed a bunch of sticks to the outside of the hulls to hold them in alignment. Jrlee checks that the decks are parallel.

Step 8: Glassing

Jrlee mixes some epoxy. We cut and lay out strips of fiberglass cloth on a piece of plastic on the deck. We soak the cloth with epoxy. We layup the glass into the hull, squeegeeing and painting the epoxy so the cloth is fully saturated. The wider strips of cloth go over the narrow strips, so the rough edges of the cloth aren't exposed.

Step 9: Rough Fairing

I mix some glass microballoons with epoxy and slather that all over the outside of the hull. When it sets up I grind it flat with a sanding disk. While I'm doing that Danny comes and suggests a better way.

Step 10: Rapid Fairing

He's glued a board to a sanding pad and glued a full sheet of 80 grit sandpaper to that. He creates an artificial snowstorm while sanding the hull, and in a few seconds it's smooth and faired. Wow.

Step 11: Glazing and Finish Sanding

Next I squeegee some body putty over the nicks and imperfections. When that's dry I wet-sand it with a sanding block.

Step 12: High Build Sanding Primer

Next come a couple of coats of fast-dry high build sanding primer, then some wet-sanding with a sanding block, and finally a coat of yellow paint. The hull is all one hull now.

Step 13: Outrigger Floats

A friend gave me some fiberglass chemical pipes. They are 19 feet long and 4.5" in diameter. I would have been worried about the chemicals but the pipes were brand new. Actually they might be intended as covers for glass pipes. I tied strings to the necks of some 2 liter soda bottles and shoved them into the pipes. The string is to keep the bottles from floating away in case of a disaster. I carved some minicel closed cell foam to make plugs for the pipes. I shaped the front plugs into the noses seen here. The flat front feature is like the "manu" on the front of a Hawaiian canoe. As it plows into a wave, it sprays the water away forming a giant air bubble around the float. The bubble rises through the wave, pulling the float up with it. It works really well.

Step 14: Float Blocks

The outrigger floats are 4.5" diameter fiberglass chemical pipes. I made some wooden blocks to rest on them. They will be the "feet" of some short legs made of stainless steel tubing. Those in turn get connected to the crossbeams. Just like Ezekiel, the foot bone's connected to the leg bone, the leg bone's connected to the thigh bone. Here I am testing the first block I made to see if it fits the pipe right.

Step 15: Cutting Curved Grooves With a Tablesaw

I setup my ghetto tablesaw, which is a circlesaw screwed to a board. Yes, it's very dangerous. Don't do it. I set up the fence at an angle to the blade. I made a lot of cuts of increasing depth in a block of wood until I had a nice round trough cut in the bottom of the block.

Step 16: Wooden Shoes

Then I repeated the process on some narrower blocks, cut holes the right size all the way through with a hole saw.

Step 17: More Wooden Shoe Cobbling

I glued a wooden disk in the bottom of the hole so the tubing leg wouldn't touch the float directly. I heated up the block to cure the epoxy quicker. Don't breathe those buttery fumes! When the epoxy was set up I shaved the protruding plugs off with the tablesaw. I drilled some lashing holes in the sides of the blocks and cut the corners off the ends so they would enter the water better. Jumping ahead, let's go sailing and I'll show you how this stuff turned out.

Step 18: Hot Spring Break

Star organized a trip to a hotspring on the coast that's only exposed at the lowest tide of the month. We camped nearby on friday night, woke up at 5 am to hike down. It's pretty amazing. There's a main pool and also a cave full of hot water that goes back into the cliff face. We relaxed in the hot spring until the tide rose and waves of cold water started washing into the spring. Then we hiked back up to the truck and it was time to put the yellow canoe in the water. So we drove to Stinson Beach and parked as close to the beach as we could. We unloaded the canoe parts onto the grass in the park there.

Step 19: Lashing It All Together

We swarmed over the canoe, lashing all the arms and legs to it with bicycle innertubes. The front beam takes most of the load, so it has a double tube 'H' shaped stainless tubing leg that connects the beam to the float. The foot of the 'H' rests in sockets in a wooden block. The bottom of the wooden block is carved to fit the top of the float tube. The float is lashed to the block with spectra string and innertube. That part stays lashed permanently.

Step 20: Carry It to the Beach

We had plenty of help from relaxed sleep-deprived pals from the hotspring trip. When it was all tied together we picked it up and carried it to the water.

Step 21: Please Return!

In case something went wrong and we lost the paddles we wrote plaintive messages on them in hopes that someone would return them. These are instant paddles made in a few minutes from a hockeystick, a board and some string, but they're so nice it would be a shame to lose them.

Step 22: Farewell Hugs

The wind had increased to a gale. The sea was rough. Time for farewell hugs!

Step 23: Raising the Sail

We hoisted the sail and watched the waves. The surfers were all on shore so we couldn't use them to judge the size of the waves. But at least we didn't have to worry about hitting them.

Step 24: Launching!

Star , Damon, and I carried the boat to the water just as a big wave washed ashore. We jumped on, sheeted in the sail, and started paddling at the breakers.

Step 25: So Far So Good

The boat took off like a racehorse. It's easy to steer with a paddle. It goes to windward just fine. We sped toward the outer break. Wait a minute. That's a big wave coming!

Step 26: What's Going to Happen?

We hit the wave and there was whitewater everywhere. We kept going through it, and when we could see again we were still moving fast and there was hardly any water in the hull. The boat works in surf!

Step 27: Sailing and Landing

We sailed around until one of the lashing buttons broke, then decided to head back in. We surfed in on a wave, outran it, and executed a perfect landing on the back of a wave. Jubilation! The boat could have handled more passengers and rougher conditions.

Participated in the Earthjustice United States of Efficiency Contest

Recommendations

Big and Small Contest

Remake It - Autodesk Design & Make - Student Contest

Made with AI - Autodesk Design & Make - Student Contest

I TRI’D – A Self-Designed 18-foot DIY Trimaran

by Small Tri Guy | Oct 4, 2013 | Self-built Small Trimarans , Small Tri Info - All , Small Trimaran Videos | 4 comments

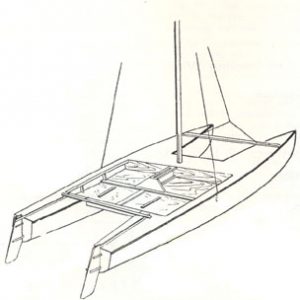

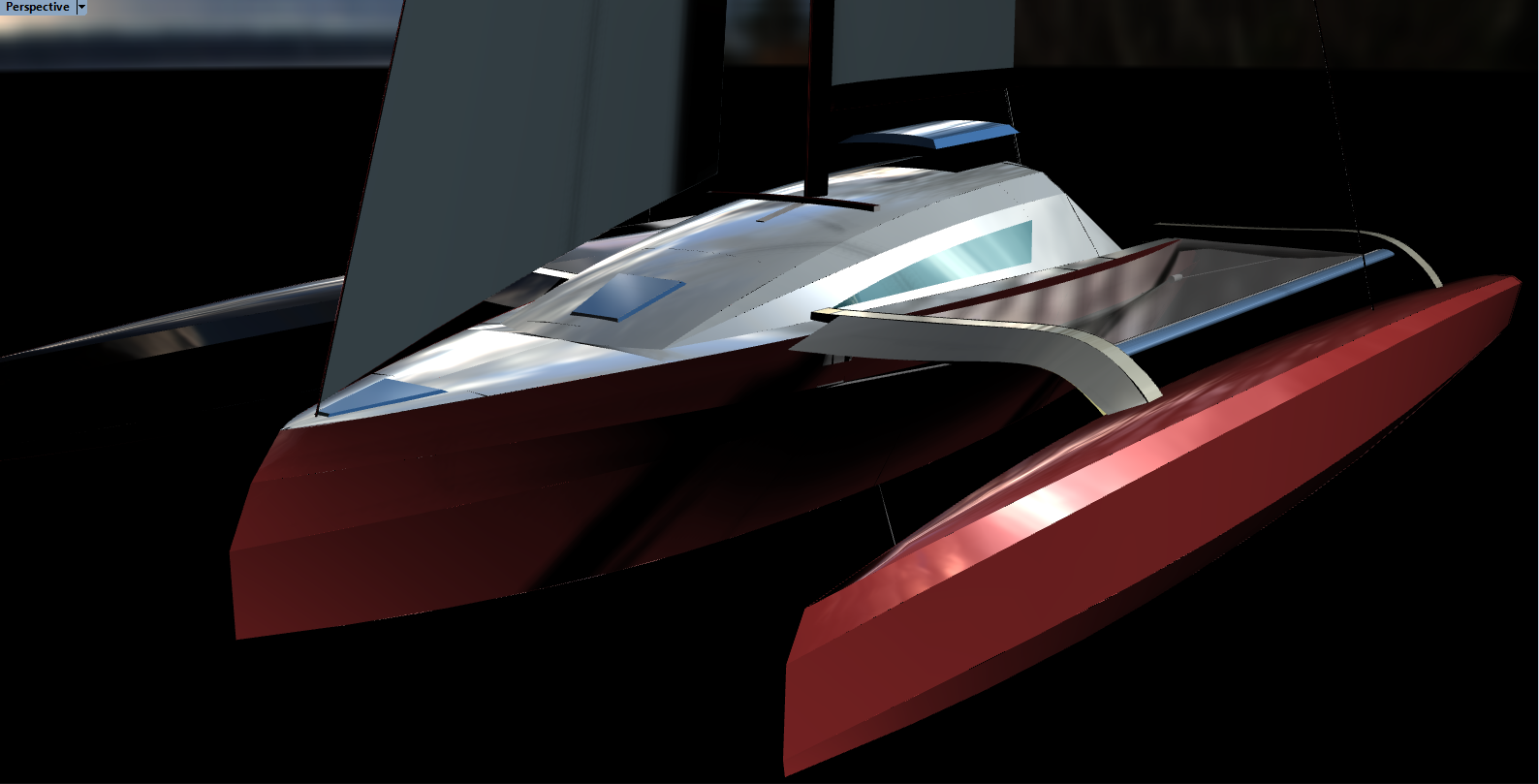

I TRI’D is a self-designed 18-foot DIY trimaran by sailor Mick Milne. He built this sailboat himself after researching lots of small tris and then using using “HULLS” software to produce dimensions for the panels.

The building technique is “stitch and glue” plywood — with the main hull oversheathed with two layers of fiberglass and epoxy. And the outriggers slide in on aluminum beams to allow trailering . It looks pretty good.

Mick learned all this stuff as he went along. But the best part is that he thinks it sails just fine.

Mick said the build took about 16 months in his spare time. This time frame was mainly driven by the weather, however, as the building took place outdoors in the UK, which, according to Mick, had one of wettest winters in years.

The first launch of Mick’s DIY trimaran was last October. What a day that must have been for him.

Great job Mick …. terrific! Thanks so much for sharing the story of your project (and photos) with us here. ( PS – Love the name of your boat too :-)

………………………….

I TRI’D – 18-foot DIY Trimaran by Mick Milne I have sailed for many years, mainly dinghies and small cats, though also a limited amount of coastal sailing in UK and around Denmark. I have never really lived on the coast so sailing as regularly as I would wish has always been a challenge.

Drawing plan for the I TRID Trimaran

A bit more research led me to view that a Tri fitted all the requirements I was looking for:

- Sailing reasonably flat

- Shallow draft

- Reasonable pace

- Trailerable – as long as it folds somehow

The more I looked, the more I got hooked, and I am one of those guys who once something gets under my skin I have to do it.

I spent a lot of time looking at designs and think there are some great Tri’s out there, but I like the problem solving aspect of designing something. I bought and read your book, “ More Small Trimarans, ” and noted the variety of different approaches, ranging from fully qualified and experienced designers to those who “just learnt as they went along”; that was enough inspiration for me to start my own.

First ama hull being built

The only real frustration was the weather. All the build was outside and I spend too much time removing and recovering the boat. If I build another (I suspect I will) it will definitely be under cover.

Main trimaran hull with crossbeam fittings

The small trimaran begins taking shape

First sail fitting with mainsail and jib from a Fireball Dinghy

I definitely expect to do some more modifications in the future. I am not a boat designer and there are things that are not right first time. The seating areas slide in, which I thought would help with the trailing width, but it all increases the setup time. I am going to raise them by about 1 inch , which will allow the outriggers to slide underneath without unlocking various pins etc. Also, I never really designed in an adequate system for mounting an outboard, currently fitted to the sliders it is secure but poorly positioned. I will change this when I amend the seats.

Blue deck paint on this small tri

Launch Day!

Sailing Cardiff Bay

To date, I’ve primarily sailed I TRI’D mainly around Cardiff in Wales. There were also a couple of trips into the Bristol Channel when conditions were favourable. The boat was planned for relatively calm coastal waters, with the expectation that in a few years we will move to the South Coast of England, near Poole, which has a very large natural harbour, with lots only accessible with a shallow draft, and easy access to get further along the coast.

Under sail with her tramps

Smaller trimaran moored with the big boats

Update 10-07-13: Mick sent me the following YouTube video featuring I TRI’D …

___________________________________________________________

Fantastic job Mick!

I’d love to see some more photos, or video of you sailing. I’m also fascinated by the reasons for people’s design choices. Why did you decide to design your own? Why 18 foot? Do you stand on the hull, or is there a floor? What sort of lee-board did you build? Is there a photo? What’s wrong with the outboard position? How long does it take to rig and launch?

Robin, thanks for your interest.

I have a video but am having problems uploading it, not my area of expertise but I will persevere, hopefully I will have that complete in the next couple of days, I will also provide more photos.

Why my own design – I think I covered that partially in the notes but in essence I think I just like to understand how things work and also I like doing things to see if they do work, and I suppose experience has shown me you can do most things if you try.

Why 18ft – I certainly wanted something I sat in rather than sat on, but had also read in many places the advice not to build a boat bigger than you need. Once I started designing 18ft provided enough space to seat two easily, four at a push, and provided enough displacement. I did sketch out some 16ft designs but they just seemed to be too small.

There is a floor, simply 18mm plywood , raised about 4-6 in from the hull base, this seemed to make sense rather than walking on the hull. Surprisingly there are no pictures but I will take some and post them.

The leeboard is simply plywood sheet shaped, but is already showing signs of stress. I am busy reinforcing a hardwood centreboard (with epoxy and fibreglass)which I will use to replace the plywood. I got most of the ideas for the leeboard from Frank Smoot’s excellent website which has featured several times on this blog. His explanations and points, such as that shifting a leeboard to change the CLR, really helped. There are some photos showing the leeboard which I will post.

The issue with the outboard position is the mounting bracket, not the outboard itself. As the slider mountings are round, and close together, I have had to modify the outboard bracket, the bracket obscures access to the slider locking pin and also applies enough pressure to the mounts to restrict free movement of the sliders. This means I am continually slackening or tightening the bracket , or removing it. It is just not a good piece of work. If I was designing the same boat again I would fix a wooden square bar 4-6 inches behind the slider mounts to provide easy location of a standard outboard bracket.

Rigging and launch takes around an hour though part of that is due to the launch site I use. Good launch sites are rare in UK and it is a busy site. I have to rig the mast, the jib , outboard, and seats at a trailer area, and then having reversed onto the ramp extend the outriggers and tighten the tramps, then launch. I then normally rig the main on the water. Part of the work to modify seats, outboard mount and a few other small tweaks is to reduce this time, though I do think rigging the boat is part of the experience so I would not want to have no rigging to undertake.

I hope all that that helps answer your queries and I will put together some more photographs showing some of the detail, and hopefully that video.

Love it, Mick. I’m always excited when any bold venture sets out to, not only build, but design their own trimaran. I’m on maybe my 10th “home brew” tri now, and each one has been not only a blast to build and sail, but a real education as well. My latest (a 19-footer) is probably my best so far. Set-up time was always an issue for me, too, which is why I ended up with a folding design and an unstayed mast with the 128 sf sail furled around it. My designs are shaped by the places I sail (shallow) and by the fact that I always beach launch. 18′ is probably the perfect length for a tri you can launch, rig, and sail alone. Your boat looks great, and I’m delighted that my leeboard info was helpful. Couple of questions, if I may: What does she weigh in at, all up? How much sail are you carrying? Have you had a chance to speed test with a GPS yet? All my boats have hit 14 mph (white knuckling it, for sure!), but I haven’t hit 15 yet. I think I will, though, with my new vertical batten sail. I’d be happy to email you some photos, if you like. Also, I now use solid lumber for my rudder and leeboards, covered in 4 oz glass. They last much better that way (I got tired of having to constantly repair them). Again, excellent job! And I liked the video as well – mainly because you kept the camera moving and we got to see most all of the boat. Cheers, “Trimaran” Frank

Hello Mick,

Congratulations for your boat ! I’m very interested in your 18 ft trimaran because i have the same project. I have some questions : Is there any drift ? where it is ? The seats are fixed under the tubes, that ‘s it ? is it a self draining background in the cockpit or not ? Did you purchase specific sails or you pick up them from an other boat, witch one ? what is the the mainsail area ? what is the weight of your boat ? You designed your boat with what software ?

Thank you for your reply Best regards x.lemaire

Submit a Comment

Your email address will not be published. Required fields are marked *

Notify me of followup comments via e-mail. You can also subscribe without commenting.

Blog Post Categories

- Production/Commercial Small Trimarans (291)

- Self-built Small Trimarans (678)

- Small Trimaran Audios (30)

- Small Trimaran Videos (289)

- Trimaran Design, Rigging, Construction Info/Links (222)

- Contact “Small Tri Guy”

Wayne Barrett has been building boats for 50 years, many of them world renowned. His latest venture is a DIY trimaran kit that embodies his half-century of expertise and celebrates “the joy of building and sailing your own creation”.

21 April 2020

Advertisement

Famed in multihull circles and the creator of high profile vessels such as Trilogy and Indian Chief designed by Tony Grainger, and Traveller, the 50-foot tri designed by Dick Newick, Wayne Barrett describes himself as “a little guy designing boats on the kitchen table in an apartment on the Gold Coast, with a nice view over the lake.”

He has built some “100 or so boats” over the years and his passion and prowess have inspired him to create the M80 trimaran, an 8-metre vessel designed with the home builder in mind; those with limited time or space, and some basic experience with hand tools.

The versatile M80 can be specified for cruising or racing and the larger 9-metre design will have a range enough to sail across the Atlantic.

“In 2021, I’m planning to sail the 8-metre boat up to The Whitsundays as a promotional exercise to showcase the vessel. It’s very manageable for single-handed sailing.”

The concept arose from Barrett’s belief that sailing should be within everybody’s reach.

“I’ve built quite a few complicated, high-performance multihulls over the years and I’m aware they consume time that’s way beyond what an amateur could devote to a build.

I used the flat panel concept, adapted to tri design and put it out there for amateur or professional builders.

“A friend of mine I’ve been sailing with for 40 years needed a new modern Buccaneer 24, a plywood 24-foot Crowther around in 1966. I’ve built a few of them, and a B33, B40 and a Spindrift 37. I thought about it for a year or so, then did something about it.

The spiritual successor to the Crowther Buccaneer 24, Mojo, was originally designed with a central cockpit, a double bunk down aft and a galley and head forward, which I thought was a great concept. But I scrapped that idea and went with a conventional aft cockpit.”

The first boat, in Brazil, set sail just over three years ago and since then, Barrett has sold plans around the world.

“A mate of mine from Geelong, Andrew Johnson, is building one at Lightwave Yachts at Coomera on the Gold Coast with the guidance of Roger Overell. It’s well into the final stages and will be used for cruising. It’s made totally from carbon, so it’s light and strong.

“There’s another one being built in France, a 6-metre design being built in Melbourne and a 9-metre design close to completion in The Netherlands. I’ve sold 9-metre plans to Germany and one in Sydney, revised to be all flat panel, foam and round bilge, with aesthetics to suit that owner.”

The main attributes of the design that have such broad appeal are its simplicity and economical package.

“Initially the concept was built around plywood, which has been a common material for 100 years and most people are familiar with it,” explained Barrett. “The benefit of ply is that a guy can build it in his own shed, over time. But other than the 9-metre in The Netherlands, people are all keen on the foam and epoxy.

“Foam and epoxy is a bit more costly, but comparing the total price is attractive for an amateur builder. It can be built from CNC cut panels in a fraction of the time compared to some other options, alternatively you can build it from our easy to follow plan set for DuraKore, DuFlex or foam core kits.”

Barrett has worked with ATL Composites for the past 25 years on numerous projects, including the 9.2-metre Trilogy, which held the Aust Championship title for around 10 years, Traveller and the 13-metre Gary Lidgard-designed cat Saloon Bar .

“I also built a 7.5-metre caravan which appeared on the ABC program, ‘New Inventors’ five or so years ago,” continued Barrett. “I used ATL Composites ’ products, including foam and resins.

“ATL spent a lot of time scanning the surface of the moulds so we could get an accurate pattern for the shapes of the foam core. I built five of them, all custom designed and built, all traveling the country. It was a fantastic looking thing!

“ATL has always been fantastic to me, in their general support, timely supply of goods, always bending over backwards to help.”

Getting started is straightforward, according to Barrett.

“People buy the M80 plans, complete with DXF files and they can have all the flat components cut out with CNC or jigsaw by hand”.

“If you have plenty of time, it’s cheap. An average handyman or woman, with basic experience with hand tools could put it together in their garage or workshop. In The Netherlands it’s being assembled under a tent to keep rain and snow out. Where there’s a will, there’s a way to boat the world over.”

trimarankit.com

atlcomposites.com

Your next adventure

Caribbean nostalgia

Don't miss out!

Subscribe to our newsletter for yachting news, reviews and events.

Lunada Design

Creative Boats for Home Builders

Category archives: plywood trimarans, back bay sit on top kayak, a modular system approach to sot kayak sailing, paddling and mirage drive propulsion.

Sit-On-Top (SOT) kayaks are easy boats on which to learn to paddle. They have none of the “get in the coffin and you are about to drown” psychological identity that one finds in the Sit-Inside boats and they’re amazingly adaptable to a wide range of paddling activities. It also doesn’t hurt that they are pretty straightforward boats to rotomold, which makes them very cheap to produce in large numbers.

I didn’t envision just one boat for this niche in the home-built kayak market. Instead, it came to me that there would need to be at least three models that could address the wide-ranging styles of boating interests in this area of the kayak world. The result was a couple of very clean, SOT models at 14’ and 16’ called the Corona and the Back Bay, respectively. The third model was going to be called the Wahoo, as it was specifically designed for the folks who spend a lot of time fishing with their SOT’s. I’ll get to the Wahoo in the next article.

As a canoe and kayak sailor and a guy who had just been out for a test drive on the Hobie Adventure Island, which is based on their 16’ SOT Adventure model, I wanted to offer my own take on what makes for a truly fun and stylish, sailing SOT kayak. The result was that a fully integrated system of component parts was designed for the basic Back Bay. This modular approach allows the Back Bay to go sailing by simply adding a system of light-weight, easily built elements that quickly convert the SOT to a single aka sailing boat called the Scorpion, OR, to a double aka sailing boat with slightly larger ama volume, called the Doubloon. Of the two configurations, the Doubloon is most like the well-known and highly respected, Hobie Adventure Island.

The Corona and the Back Bay are virtually identical models, save for their respective lengths. For the purposes of this article, I’ll focus on the Back Bay version and all the potential add-on systems I’ve incorporated in the design.

THE BACK BAY SOT KAYAK

Specifications: Length overall – 16′ Beam overall main hull – 28″ Depth of hull max – 12” Weight – 48 lbs. or less Displacement – 335 lbs.

This boat is built in the S&G style of construction in 4mm marine ply with 6 oz. plain weave fiberglass set in epoxy on the inside and outside of the hull for full laminate sandwich strength. The build process uses external cradles as building supports, ensuring that the hull goes together with minimum hassle when handling the rather slender and longish hull panels. The boat is bulkheaded internally at three key points. These bulkheads create not only integrated strength in the design, but they also cleanly separate the hull cavity into four unique volumes for gear storage and watertight flotation.

The Back Bay can be configured with a large, open tankwell set aft of the cockpit, or built with a watertight, aft hatch cover for internal storage in a conventional kayak style.

Specifications: Beam overall – 10′ Weight (est.) – 90 lbs. Sail Area – 56 sq. ft. Displacement – 350 lbs. Draft (board down) – 28″

The Scorpion variant is a Sit-On-Top design for fun sailing, paddling, or Mirage peddling… or all three, as the builder desires. There will be a design for a leeboard mount included in the plans for those who are going to build the boat for sailing. Having the aka gull wing form set well forward permits a full paddle swing arc. The aka beam connectives to the amas is split into a pair of mounting elements. I did this to make for a stronger, single beam mounting struture. With a single beam design, there is a tendency for the am to want to rotate around the beam, making for a very stressed component that could lead to early failure. By splitting the beam and spreading the mounting points, I have given the structure more resistance to this rotational force, making for a more rigid boat in use. This setup will allow the owner to power sail in light air with both the paddle and the sail providing thrust. With the leeboard swung down for sailing, the owner can do some “power sailing” and utilize the Mirage drive, as well as the sail, in light conditions. The Mirage is capable of boosting boat speed enough that it creates apparent wind over the sail, adding power where there really isn’t enough for sailing alone.

The amas are positioned to optimize capsize resistance when sailing off the wind. The amas do not touch the surface of the water at rest in stable trim and provide only minimal wetted surface drag when underway by paddle or peddle. As soon as the sail is loaded by the breeze, though, the ama on the lee side begins to immerse, firming-up the boat and resisting the heeling moments being generated.

The aft deck can be configured as a watertight hatch with full access to the aft sections of the hull, OR a large, diving tank well with self-draining ports. The cockpit is fitted with self-drain ports under the seat as well as forward, in addition to the daggerboard slot. There is a watertight deck plate just forward of the seat, between the knees of the sailor/paddler to provide secure storage for critical items that may be needed on a routine basis. The foredeck has a watertight hatch cover for bow storage needs.

The rig is a fully battened Dacron sail with two reef points and a multi-section, self-supporting mast which steps into a sealed mast socket in the hull. The mast and boom sections can be aluminum or carbon, as budget permits. The sail choice is open for the customer as long as it can be balanced with the fixed positions for the mast and dagger board. The Cunningham is run to the deck of the gull wing aka to keep the rig on the boat in the event of a capsize.

With 56-sq. ft. of sail on a 90-pound boat, this will be a decently speedy boat without being in over its head all the time in a stiff breeze. I suggest two reef points in the sail to allow for sailing in a wide variety of conditions.

This will be a wet boat at speed, yet there are no worries at all for flooding and sinking, save for a truly nasty trip over a reef that shreds the entire underside of the craft. The bow, cockpit and aft hull volumes are all independent, sealed compartments, as are the ama volumes.

Reentry from a swimming session will be easy with a simple, sling, or rope ladder much like those used by rock climbers, called etriers.

The boat is constructed in a multichine, marine plywood style with epoxy glass laminates inside and out in a stitch and glue style. Stainless T-Nuts are embedded in the hull deck surface from below to provide a secure set of mounting points for the aka wing. The amas are held in place on the aka tips by large bungees and a notched lock system. This system provides for quick setups on the beach.

You just fit the aka to the foredeck, insert four, 1/4″ threaded stainless screws with comfortable, knobbed grips and screw down the aka wing. The amas slip onto the ends of the aka and you lift the pair of 3/8″ bungees up and over two raised hooks on the aka ends to secure the ama in place. Simple, easily maintained and near foolproof in operation.

DOUBLOON SAILING SOT

The Doubloon is the second variation on the central SOT theme of this group of boats. In this design, I am looking to provide a more expansive utility application for the base, Back Bay SOT version. The Doubloon is essentially a solo craft and it carries the same, 56 sq. ft. sail, but the overall potential of the boat is expanded through the use of dual akas and full trampolines on both sides of the Back Bay hull. The rendering of the Doubloon shows a daggerboard inserted down through the Mirage Drive trunk, but in use, I would prefer to have the board mounted outside the Back Bay hull as a leeboard. Plans will be supplied with the leeboard solution.

The akas on the Doubloon are spaced to allow for a full paddle stroke with the boat setup as a trimaran. There are two sections of tubing that span the opening fore and aft between the akas from which the tramp is mounted. The trampolines are designed to roll-up on the outer tube section, much like a window shade and they are deployed by an endless loop of light halyard line. With the tramps fully deployed, the inner tube section lifts up and over a holding pin in the aka and the sailor applies as much tension to the tramp as he feels he needs by hauling-in the endless loop line and cleating it off. If a paddling session is desired, he simply pops the jam cleat and pulls the line to roll-up the tramp on the outer tube section. This procedure applies for both port and starboard tramps.

Like the Scorpion, the Doubloon can be built to utilize a Mirage drive in the center well and the need to roll-up the tramps for paddling is essentially negated, (though it is nice to have the option once in awhile as Mirage drives can be difficult to maneuver in tight places)

The aka beams are held to the deck of the Back Bay hull with the same, threaded knob strategy for quick setup and takedown times. Similarly, the amas are held to the aka ends with hefty bungee cords for the simplicity of use. There’s another, rather invisible, benefit to using the bungee cords for ama mounting. Because they are being held in place through a fairly dynamic hold-down system, the amas can move about, ever so slightly, while underway. This allows the amas to have some structural “give” and the result is that the banging and thrashing that is typically experienced by the ama, is somewhat dissipated through the flex of the joining system.

All in all, I think the Back Bay SOT should be a really fun boat to own for warm water/warm weather boating adventures. It has the capacity to carry enough gear for several days out on the water. When rigged with a sailing system of your choice, it can also cover some pretty good distances if the winds are favorable. Plans for this boat and all its variations will be available from this site and Duckworks Magazine.

Chris Ostlind

Lunada Design Chris@Wedgesail.com

Solo 12 and 14, corsica 15r, sports car performance on the water.

Over the past couple of years, I have taken a break from my boat design work. During that time, I’ve been able to reassess my connection to the craft. The last boat I designed was the Europa 20, which is a trimaran meant for vertical strip foam construction with sandwich style, infused epoxy/glass laminates inside and out. The Europa is a boat for very fast day sailing with a very light hull and a very big rig. A boat that is not for everyone, to be sure, as it requires a level of skill that the average guy does not typically cultivate in the course of experiencing their recreational boating interests.

In stepping away from the larger, more powerful beach type multihulls, I came around to the desire to produce a smaller, very quick and sensitive boat that would appeal to recreational sailors and not just those guys who want to blast around with their hair on fire (though I do suspect that in the right hands, this boat will do just that). The new design had to be easy to build with standard, marine plywood/epoxy/glass techniques that did not rely on exotic layups with spendy carbon cloth. (Well, maybe the carbon will sneak in there a bit on the beams for the guys who want to play with a bigger rig)

Looking long and hard at the smaller skiff-like hull designs I had done before, such as the Montage, I decided to draw the new boat in that same general size, but with a very different approach when it comes to how the boat achieves its performance potential. Where the Montage has a relatively spacious cockpit capable of taking on a couple of adults, (or a parent and a couple of smaller kids) the new, Corsica 15R trimaran would be for one adult (or accomplished kid) designed solely for a unique, one-up sailing experience within the small beach multihull genre.

As a result, the boat has minimized clutter when it comes to excessive high-tech trickery. With that approach, the Corsica 15R is also going to be a boat that has much lower maintenance requirements in order to keep it in top sailing condition, as well as a much lower realized cost to get it on the water and ready to sail.

If you are into cars, as I am, then think in terms of a nicely pumped, Mazda Miata, type of boat that would be a cool, weekend canyon racer for one person. A boat that could blast around the local waters in a good breeze and give chase to other small, fast, multihulls being sailed by crews of two.

The result of this conceptualizing process is the Corsica 15R. The C15R is a boat of modest, marine plywood build techniques and is very light weight for its generous sail area. With this boat, the normal sailing position would be the skipper, semi-reclined within the main hull, driving his machine like an F1 Grand Prix car. In this configuration, the boat is designed to utilize foot pedals for steering, leaving the hands free to work the sheets. But, that’s not the only way to sail this boat. Owners who wish to sail in a more conventional multihull style, can sit-up out of the cockpit and onto the main hull cockpit gunnel, or even the trampoline surfaces all the way out to the ama, where they will steer with a tiller extension.

A construction style in multichine, 4 mm marine plywood, allows the boat to be assembled in a well-understood fashion that will go together quickly. With a subtle placement of minimal stringers and sufficient bulkheads, the C15R becomes a strong main hull shell that can absorb the loads from its sizeable rig, turning the power of the sails into forward thrust in the water.

There is no fully enclosed transom on the vaka hull. The cockpit deck is slanted gently down and aft for automatic self-draining, such as is seen in sport dinghies and larger race boats. A collection of bulkheads under the cockpit deck provide structural support and watertight compartments ensuring that the boat will not likely sink even if large sections of the bottom are torn out from an underwater hazard while smoking along in a gin clear lagoon.

The demounted boat can be assembled easily by one person. The gently gull-winged akas are built with a glassed box beam core. The inboard ends of the akas slide into tapered sockets in the main hull and are levered in place with stainless waterstays to make ready for sailing. This, tapered socket technique prevents binding while assembling the boat, while providing a solid, hassle-free and weight minimized demounting system. The leading edges of the akas are smoothly shaped foam blocks that are glassed onto the box beam to provide an aero component, as well as creating reduced drag from waves and spray. The akas are hard fastened to the amas as a complete assembly that is easily removable from the vaka hull. The trampolines stay mounted to the akas and amas for transport and only have to be hooked and tensioned to the main hull during assembly.

The mast is a stick from a Hobie 16. I specify the addition of a set of spreaders from the Hobie 18 mast to stiffen up the H16 mast to handle the additional righting moment generated by the Corsica design. Naturally, I’d prefer to see fresh sails in something like fully battened, Pentex laminate, but builders on a tight budget could also work with a loft service to tweak a reasonably fresh Hobie 16 main and jib and do just fine. The addition of reefing points on the main are strongly suggested, as well as the use of furlers for the jib and spinnaker/screacher. For those who desire fresh sails for this boat, I would recommend the folks at Whirlwind sails in San Diego, California. http://www.whirlwindsails.com/

A removable carbon prodder sets the tone at the front end of the boat. The stick originates as a carbon windsurf mast, so it is easily found on the used market and equally replaceable, should it get poked into an unyielding environment. For trailering, the sprit unpins, slides out of its socket and is stowed in the cockpit for transport and storage.

Corsica 15R Specifcations

LOA 14’ 11” (4.54 m)

BOA 13’ (3.96 m)

Displacement 650 lbs. (294.8 kg.)

Sail Area (upwind) 218 sq. ft. (16.17 sq. m)

Spin 142 sq. ft. (13.19 sq. m)

Mast Length 26’ (7.62 m)

Draft (board up) 1’ (.3 m)

Draft (board down) 42” (1.07 m)

The mast is raised by the traditional beach cat method of physically lifting the mast with the base pinned to the mast step, or by utilizing the long daggerboard in its trunk as a form of a gin pole. A forward hoisting line is led over a pair of sheaves at the top of the daggerboard and down to the hand cranked winch on the trailer. Mechanical leverage quickly raises the mast so that the forestay can be fastened to the bow, stepping the mast securely. You can see a few photos of the process at Brent’s L7 trimaran site:

http://home.comcast.net/~ritakend/site/?/page/Mast_Raising/&PHPSESSID=864f3404e3f46ed29dd99b863018fc1d This is a very simple way to raise a mast should you need to avoid the trad lifting exercise for one reason or another.

I chose to not go with tricked-out, curved lifting foils in the amas due to construction complexity and added cost for the builder. Foils of this type are hard to build correctly by hand, as are the needed curved trunks in which they slide. Instead, the boat is equipped with a daggerboard that is inserted through the deck of the main hull in front of the mast which angles aft to exit the hull below the waterline. A daggerboard and trunk of this type are much simpler forms to build and orient in the hull. It is also just one main foil, where lifting foils need to be made in pairs, one for each ama. Lifting foils also need complex control mechanisms to retract and deploy the foils and they have to work from the cockpit remotely with the foils mounted way out in the amas. The needed controls are an interesting problem when the boat is 13’ in width and the driver is semi-reclined in the main hull.

Note: I’m not against an owner who might want to experiment with foiling for this boat, even if it is just foil assist and not full flying. It would require a lifting t-foil style rudder and twin Bruce style foils in the amas, or, if a person is really accomplished as a composites builder, they could make a pair of matching c-foils for the ama. The owner just needs to know what level of additional work is involved and at what skill level they need to perform in order to get the desired result.

If you are on a budget, the rudder and headstock from a Hobie 16 will work just fine for the Corsica with some mods to the tiller. The more deluxe, Rudder 25 system from Dotan will also work well, should you have the coin. http://www.dotan.com/ If you plan on pushing the boat hard, then a longer blade will be required, or you can get yourself invested in the process of putting a rudder on each ama and have stunning control at your finger tips. On the down side, that change will cost you a bit out of your pocket and at the launch ramp in setup time… though I can see a nifty rig with light alu tubing and the use of snap buttons as a cool solution.

The Corsica 15R will be a light boat built from familiar materials. It should be a fairly simple building experience for the owner and will fit comfortably into any typical garage space, making it easy to find a building location. It will quickly assemble for sailing and be hassle free with minimal maintenance required to keep it in top form. It can be towed behind any compact car on a typical beach cat trailer and when demounted for travel, is road legal anywhere in the world. On the water, this boat should be quite quick and behave with predictable, pin-point sailing manners. With the skipper slung comfortably in his reclined cockpit seat, he will be decently protected from the effects of the weather and sea state while tearing around his local waters.

NAGARE 21′ AND 17′ MIRAGE DRIVE SPEEDSTERS

Making use of mirage drive propulsion with more efficient hulls designs.

Nagare (nah-ga-ray) is a Japanese word meaning Flow.

Both of them are configured as trimarans with fairly small and unobtrusive amas designed to give the boats remarkable stability in a wide range of conditions while allowing the vaka, (main) hull to be decidely slender for more effective drive through the water.

The Nagare sisters also have incredibly narrow waterline beam numbers that, when coupled with their fairly long hulls provide for very easily driven hull forms for high efficiency per unit of energy applied.

I expect both boats to operate at the very high end of commercially available paddled boats of the same length, beam and weight. So, yes, they can go pretty quickly, but that’s not the real purpose.

The real benefit of the design genre is through the ease with which they are propelled at any given speed, compared to other boats of their size. This efficiency translates directly to those using the boats as less tiring for miles covered, or greater speed with the same effort as other, wider designs.

Because the propulsion is derived from the largest muscles in your body, the leg muscles, rather than the arms and shoulders, there will be less fatigue for each mile traveled. Because leg muscles are so much bigger than arms, they will be able to do more work in a given period of time, making for longer possible trips, as well as the mentioned lower fatigue issue. With a less fatiguing effort, more people will be able to enjoy the experience of being out on the water for daylong adventures.

NAGARE 21 DOUBLE SPEED AND STABILITY FOR DOUBLE RECREATIONAL BOATERS

The Nagare 21 uses a set of amas, mounted on a pair of simple, anodized aluminum tubes with quick release snap buttons holding the sections together for easy disassembly for car-topping. If a trailer is used to transport the boat, the beam of the Nagare 21 falls well below trailer maximums, so nothing special needs to be done to take the boat to and from the water. Two Nagare 21’s can be trailered, or car-topped, by removing one of the amas and placing the main hulls close to one another on the racks, or trailer. The removed amas easily fit inside the hulls and they are ready to go. The whole affair on the rooftop is very much like a pair of sea kayak doubles. Because of the length, I would not mount a boat this big on any compact cars. You would be very likely to rip the rack right off the roof in strong side winds.

Steering is by means of a simple, flip-up style kayak rudder with control lines run through the hull to a convenient steering lever in the cockpit. I suggest the SeaLine SmartTrak rudder system (do a search for supplier), the P-41 Multi-purpose rudder from Onno Paddles http://www.onnopaddles.com/onnocomponents.html and the Feathercraft rudder system for hardshell boats. http://www.feathercraft.com/accessories/rudders-hardshell.php These are really great rudder units and will give excellent steering control with minimum drag.

NAGARE 21 SOT OPTION

This boat can be built with a full cockpit tub so that it functions as a Sit-On-Top kayak with full drainage through the Mirage drive openings. Auxiliary drain ports are located in the tub for rapid removal of any water that comes in over the side of the hull. I suggest the SOT option for warm water users, with the more traditional kayak style, Sit-Inside hull form for those who will be using the boat in colder water, or more frequent inclement weather.

The SOT version has internal bulkheads for support of the SOT tub, along with the capability of adding a small circular deck plate for an additional watertight compartment in the cockpit that is perfect for small items, such as cameras, wallets, car keys, etc.

The SOT variation is an optional element to the base plans. If you wish to built it as an SOT, drop me an email at my regular email address and I’ll get back to you.

ROUGH WATER USE

This is not really a boat that is meant to go out in rougher conditions, such as those where a full-blown sea kayak might be right at home. It’s meant for quieter waters, such as lakes, bays, harbors and bigger rivers. It can take a session in 1 or 2 foot breaking surf, but I would not expose the boat to bigger waves, especially in a shore break scenario. You may find yourself out from the shore a bit when the wind comes up, producing steep, choppy waves. The basic Nagare 21 will handle this easily because only the cockpit will be exposed to swamping. The amas will keep the boat stable while you pedal to shore, or a quieter place on the water, where you can bail-out the boat and continue.

It is a perfect boat for sightseeing, bird watching, fishing, photography, and just simple, energy efficient cruising with near bomb-proof stability (you can stand up in the boat while out on the water without your partner coming completely unglued, for instance).

The Nagare 21 is a fast, comfortable and unique boat for a couple who like to get out on the water, but do not want to hassle with the business of capsize that is present in other types of boats, such as kayaks and even canoes.

NAGARE 17 SINGLE A NEW STYLE OF SOLO BOAT FOR TROLLING FISHERMEN

The solo version of the Nagare series has some very different twists, compared to its bigger sister. It has the same, highly efficient and easily driven, slender hull technology, the same set of trimaran style amas well aft for big time stability, the same generous cockpit opening and the same convenient utility for car-topping or lightweight trailering.

The design elements that set this particular boat apart from its sister craft is that the Nagare 17 has a very special capability when it comes to fishing.

AFT FACING TROLLING

Anybody who builds the Nagare 17 and intends to use it for fishing will probably be knocked-out by the potential for facing aft while trolling. Imagine using your legs to quietly drive the boat forward while you casually set trolling rigs, eat a sandwich and keep an eye on the fish finder… all while keeping an eye on the rigs you have set, with them easily at hand?

This is the signature utility development with the Nagare 17, designed specifically, for fishermen. It works like this…

The fisherman loads his boat, drops into the forward facing seat, hits the iPod for his favorite tunes and jams out across the lake at a remarkable speed for a human powered boat. He zips across the lake in virtual silence because he’s driving a very skinny and efficient hull with no engine sounds. Once he arrives, he’s going to make a few sneaky trolling passes with his Mirage drive pushing him along over that monster crew of Pike that are hanging around on their favorite piece of structure. Wham! Fish On! and the day starts with smile on his face.

If you’ve ever fished from a typical Sit-On-Top, you know that you have to face forward while trying to look over your shoulder while trolling. Hook-up and then you have to swivel around, grab the rod and go after the fish. All the time you are doing this, you have to balance the boat carefully, because the whole tamale could go over and end your day right then and there.

Well, that’s how you used to do it, anyway.

With the Nagare 17, you can take it to a whole new level of fishing pleasure. The Nagare 17 is equipped with twin Mirage drive trunks. When driving the boat forward and facing forward, the Mirage drive is dropped into the forward trunk and a tractor-style seat is dropped into the aft trunk with the seat bottom resting on the top of the trunk.

To convert the boat to aft facing trolling and fishing, you simply stand up in the boat and swap the Mirage drive for the aft mounted seat plug and the seat then goes to the front trunk… facing aft. With the Mirage drive still set to drive the boat forward, you simply sit down and start pedaling, slowly, up to your desired trolling speed.

Now, you can watch your fish finder, GPS and your trolling rigs while you continue to tool along at your favorite speed for nabbing the fish. Get one on and simply work that rod while continuing to face aft. No twisting around in your seat, no ”just about dumped it” scenarios, just simple, fun fishing in a very stable boat. What could be cooler than that?

With the fore/aft balance point of the boat set right between the two drive trunks, there is but a very minimal change to boat pitch when you change the direction you face.

The Nagare 17 is further designed to accept an insulated and watertight tank between the two aka tubes where they run through the aft deck. You can use this for all kinds of stuff like: your catch, fresh bait storage, cold beverages if you catch and release… whatever suits your needs. There is plenty of room between the two drive trunks for a pretty good sized tackle box and lots of room up forward of the trunks for any of that “other stuff” that fishermen seem to sneak aboard their boats.

A moveable electronics unit can be fastened at the forward end of the cockpit, or unhooked and moved around aft if you’d rather have it facing that way.

Maybe you want to cast lures or flies instead of troll. The boat is so stable with the two, wide set amas, that you can stand up and cast all day without ever feeling like you are getting the least bit tippy. All in all, the Nagare 17 is quite a boat for fishing, as well as just plain fun, recreational pursuits.

The Nagare sisters represent a unique design family for human powered vessels. They are quick, stable and with their unique styling, represent a distinct departure from the looks of traditional boats one typically sees on any given shore or launch ramp. Both boats are designed to be built in marine ply Stitch and Glue methods for the hull sections, with cedar stripped decks to take advantage of the really beautiful, smooth curves capable from that style of building. You can paint the lower sections of the hull and leave the cedar decks natural with a deep varnished finshed, for a real knock-out boat that will really gather a crowd.If you really want to have a plywood deck build instead of the cedar strip build, write and twist my arm gently. I can design that change for those who really like to build that way

Plans are not yet complete, so if you would like to build one of these two boats, please send me an email and I’ll put your name on the mailing list for information, or watch the plans section of Duckworks for the notice.

CHRIS OSTLIND LUNADA DESIGN CHRIS@WEDGESAIL.COM

Another Trimaran/Skiff … Bigger, With More Power

Well, you had to know this would happen…

When the Montage Skiff/Trimaran was introduced, the Lunada Design website was absolutely flooded with an ocean of page hits every day right after the article was posted. I received several dozen personal query letters regarding the boat and sizeable slice of them were directed at the potential of a bigger version of the Montage.

The concept of being able to build your own boat and rig it with a used mast and possibly even used sails, (if they are in good enough condition) had struck a chord with the homebuilding community. The creation of a larger version of the Montage would take the specified rig choices up into the much more commonly found beach cat rig sizes and make the business of finding a used rig in great shape, a whole lot easier. After pencilling a collection of thoughts and running some rough numbers on the potential, the idea came into focus as the 18′ Collage.

The ama shapes, especially on the smooth hulled variation, borrow other design cues from the modern performance dedicated French designs of VPLP, as well as the very cool work of Nigel Irens. The transoms are nudged in the direction of a triangular shape, while retaining some of the typical beach cat, flat-topped U-form feeling. The volume concentration is well-forward, with the foredecks being much more rounded to provide rapid shedding of water. These shapes will help to reduce the tendency of multihulls to pitchpole when sailed hard.

Breaking away to some degree, from the single, build style of the Montage offering, the Collage is presented as a fully strip built, smooth hulled version, as well as a multichine plywood version. These choices will give builders the ability to work with the material choices and aesthetics they prefer. I am also looking at the potential for a foam cored sandwich laminate boat using the vertical strip technique, though that iteration will probably come around a little later in the process.

Collage Specs

LOA 18′ ( 5.48 m ) BOA 14′ ( 4.26 m ) BOA main hull 41″ ( 1.04 m )

Sail Area Main 163 sq. ft. (15.14 sq, m.) Jib 55 sq. ft. ( 5.12 sq. m. ) Spinnaker 161.5 sq. ft. ( 15 sq. m. )

Displacement 1000 lbs. ( 454.5 kg. ) Weight 380 lbs. ( 172.7 kg. )

The Collage meets all the same design criteria as does the Montage, except it’s longer and wider, has more sail area, carries more crew weight and yes, it’s going to be faster in the right hands. Faster… sometimes this term can be kinda self-defeating when speed claims are made compared to another boat. When it comes to recreational boats, I’m of the opinion that speed is a relative thing based on the overall design brief of the boat in question. In the case of the Montage and Collage designs, speed is one of the attractive elements as long as it is kept in perspective with just what the use application will be from day to day. From where I sit, this will be primarily recreational purposes.

The Sail Area to Displacement ratio ( SA/D ) for each of the boats is as follows: The Montage is 31.56 and the Collage is 34.88 With both of these boats being sailed at near max displacement, I give the nod to the Collage, based on waterline length, as well as the ability to punch through wave conditions that will toss the Montage around to some degree.

I would like to see this pair of boats ( Montage and Collage ) blasting around in the hands of skilled sailors. There’s nothing quite like the feel of a performance boat and the way it can deliver the exhilaration of a spirited ride. But… I’d also like to see this boat out on the water being used by families while they have a really fun day on the water with, maybe, a somewhat toned-down speed blast tossed into the mix every now and then to get the kids chirping.

I’m looking at the potential for the Collage to create a new beach and/or lake sailing culture in which energetic hot shoe dudes, as well as young sporting families, can all mingle on the beach, out on the water and share a communal BBQ after the day of sailing. I grew to maturity on the beaches of SoCal watching the brand new Hobie Fleets do this very thing and it was a lifestyle that perfectly fit my beach kid way of thinking. It would be great to see that happen once again. Could this take place in 2009? Hey, I don’t know the answer to that one, but it is fun to think of the boat and its owners in those terms.

There’s a lot going for the Montage/Collage design approach to support such a social event concept. Both boats are affordable to build, they are easily trailered by even sub-compact cars, they make use of “experienced” parts that can be had on the open market for pennies on the dollar when compared to new parts and they are boats that are easily sailed on the first day. This last part is important, as the boat will attract more enthusiasts when they see that they can be sailed with what pretty much passes for beginner’s skills. Just because it can go fast, does not mean it has to be sailed that way. As the owner’s skills grow, the boat’s potential will be there waiting for him.

As a way of introducing the Montage and the Collage designs to the homebuilder market, I’d like to offer free plans to one person. This builder should be able to show me that they have a very strong interest in either design and are willing to build the boat as I supply the plans in accordance with their progress from the previous plan set delivery.

If interested in this offer, you can write me at: Chris@Wedgesail.com or at lunadadesign@gmail.com and make your pitch. The one chosen to receive the free plans will be willing to provide construction photos of their progress and a brief written description as to how things are going. The personal accounts will be published on this website, Lunadadesign.net so that the readers of the site can follow the projects.

Chris Ostlind Lunada Design

This boat created immediate appeal to beginning and intermediate sailors. It offers much of the speed experience of a high performance skiff in a stable and predictable platform that is really tough to capsize. The Weta is one of the first boats to encourage family participation and reintroduces the waterborne fun of the beach sailing culture, established way back in the late 60’s with the intro of the Hobie catamaran.

A brand new, factory built Weta goes out the door for USD $11K. Realistically speaking, this isn’t an in surmountable amount of money for a factory produced, brand new carbon trimaran. It is, however, quite a lot of money for most casual recreational enthusiasts and the folks who like to build their own boats… especially when you consider the rugged economic conditions we all face these days.

The estimated $5600 figure represents a boat with a whole host of brand new parts. For the clever builders out there, the Montage could be even less expensive if they can find a used 470 rig, perhaps a used small craft, or beach cat trailer that could be modified to fit the hull design and even a collection of hardware in good condition. The Montage is a very light boat at right around 235 lbs., so you do not need to buy a heavy duty trailer.

I went back to the drawing table and reconfigured everything so that the longest hull panel was going to just fit on a couple of sheets of marine ply laid end to end. The main hull also got just a bit wider in the process of lengthening the boat. Where the factory boat uses carbon fiber on foam cores for its structure, the Montage will be a 4mm marine plywood design with full fiberglass/epoxy sandwich laminates inside and out. The foredeck and the cockpit seating transitions are strip-built in Red Cedar to give the overall appearance of the boat a smoother, more organic feel than straight plywood panels.

The amas for Montage came from a 16′ trimaran design that I had already done and required minimal re-design to work with this boat. The amas are also designed as multichine ply forms with pretty high volume shapes well forward and a water shedding deck form that will helps to keep them riding high even when driven hard. Ama displacement is 100% of the all-up boat weight when sailing.

Montage Specifications

LOA 15′ 6″ BOA 12′ BOA main hull 41″

Main 110 sq. ft. Jib 38 sq. ft. Screacher 102 sq. ft.

Displacement 650 lbs. Weight 235 lbs.

The aka beams are anodized aluminum instead of carbon tubing. The inboard ends fit into fairly burly sockets in the hull and are held in place with quick release pins. Flat deck flanges on the ama ends are welded in place and bolted to the amas. The amas are removable from the aka tubes for repair or maintenance, but otherwise stay mounted, along with the trampolines, as complete units.

The mast is also anodized aluminum. The boat uses the same mast section as the 470 dinghy, which is a Proctor Cumulus section. This mast is available on the used market with a little bit of hunting around. If you want it all and have the money, then there’s a very cool, filament wound Forte carbon spar available with very close specs to the Proctor that will rock your world. http://fortecarbon.com/

Making these two changes from the benchmark, all-carbon Weta to an aluminum spar and tubing keep the costs down, with but a slight weight penalty over all-carbon parts. If you find a used mast, the savings will be even more substantial.

I have found that the more expensive sailcloth laminates are capable of driving the boat just a bit faster, but for the average recreational sailor, they will hardly ever make a difference compared to more forgiving sails in Dacron. Dacron is much easier to maintain, lasts longer, is a lot more tolerant of UV exposure and can be repaired by any sail loft wherever you go. If the builder of the Montage really wanted to, they could buy a set of sails in something like Pentex laminate instead and they’d have that hot, performance boat look that some desire along with just a bit more zip under sail.

The aluminum aka tubes will be sold pre-bent and ready to install on the amas. If the builder has access to a good mandrel bending facility that can handle the OD/ID specifications of the tubing, they can fabricate their own tubes to supplied specs.

The Montage is designed to be a really fun day sailing machine that can generate near performance skiff sailing speeds while offering a hugely stable platform for recreational sailing. Construction of the boat is very straightforward in marine plywood with glass/epoxy laminates and can be easily built by any sailing enthusiast who has household handyman skills with tools. The Montage has been created to offer homebuilders an opportunity to enjoy this style of family sport boat at a completed cost that is far less expensive than the manufactured version.

CHRIS OSTLIND

Fresh take on the solo16 s, a safe, speedy solo cruising craft for adventurous souls.

After a lot of input from readers of this site, I have completed the modifications to the Solo16 S design that reflect many of their expressed interests.

The Solo16 S now has a bit more displacement as a direct response to suggestions for the use of a small 2 hp outboard and some spare fuel. At the same time, the vaka hull was given additional beam above the waterline and the shear was raised some to allow for mods to the amas.

The amas, themselves, were made slimmer and taller, while retaining the same volume. They now have a slight vee section which gives the boat a progressive resistance increase as the amas are pressed heavily in a gust.

To complete the changes, a sporty all-weather soft cabin has been designed to allow the owner a chance to sail in a wide spectrum of conditions. The new cabin is modular in its approach with the ability to address a multitude of sailing situations.

All panels except the Bimini have generous window areas which are backed by micro mesh screen that is small enough to keep out the No-See-Ums. The PVC windows are zip-out removable and the screens can be rolled-up for maximum airflow through the cockpit. The complete enclosure system allows the owner to mix and match the panels as needed for the best protection from the elements.

When setting up the boat for sailing while on the trailer, the owner simply lifts the ama assembly, rotates and places the ends of the aka tubes into the matching vaka openings and slides the ama into place. The akas are fully seated when their internal, spring loaded snap-buttons click into place. The entire ama assembly is easily handled by one adult with modest physical strength.

In the trailering mode, the complete boat does not exceed 68″ (1.7 m) in width, falling well under every trailer width limit in the world.

Fram's Building and Sailing Pages

Introduction.

Hello and thank you for showing interest in the building story of Fram, my F-39 trimaran.

Using the “Next” button at the bottom of this page will guide you trough the whole construction process. But be warned, there is a lot of information and thousands of pictures, so it can take some time for the interested reader.

Initially, the choice for my new to build boat fell on the high-tech F-36 trimaran, a design by the famous New Zealander Ian Farrier ( † RIP Dec.8, 2017).

In those days the F-39 did not exist yet. Although the F-36 missed my preferred folding option, the design nevertheless meets most of my wishes. According to Farrier, there was simply not enough demand for a folding option for such a large trimaran. And is it not true that a boat is always a compromise ?

Actually, the determining factor to go on with this Farrier (F-boat) design was the superbly detailed building plans and the building method. The more I studied the plans, the more I realized that this boat is an engineering marvel and accompanied by an building method that I could manage. So all necessary attributes for an high quality yacht!

However, somewhere in my head I still felt the obligation to find out whether it was not better to outsource the construction to a suitable yard. Though, I had already realized that this would be far above my budget, which was indeed proven by offers from various yacht builders at home and abroad.

“The desire to build a boat ... begins as a little cloud on a serene horizon. It ends by covering the whole sky so that you can think of nothing else.“ quote Arthur Ransome

I can not deny that this state of mind led to the purchase of the building plans. A stack of paper from which a boat has to be built. This is the beginning of an almost incalculable adventure.

I bought the original F-36 plans in the spring of 2000 and planned the start of the construction process by the end of that year. But it worked out differently.

And I want some new furnishings too ................

And the kids want a bigger rabbit hutch..............

By finishing this and carry out your promises I will be ready for the project.

Of course she was right !

Update to the F-39

Autumn 2001 everything was done. In the meantime I have been searching for materials and suppliers, and have negotiated for prices and specifications. As still being a greenhorn in composites, I tried to get familiar with all these composite materials and worked on another F-36 (thanks Gary Mulder) to go through the laminating process of the main hull.

And just before I ordered the materials for the first float there was a very welcome note from Ian Farrier that he decided to upgrade the F-36 to an F-39. The new design is not only larger but also includes a number of improvements, the latest design insights, rotating mast and last but not least the folding option.

So this delay wasn't too bad at all and now I could update without any trouble and not having done the wrong things. Spring 2002 I ordered the updated plans. Not all drawings were ready yet but there was enough to make a start.

In the spring of 2003 the form frames for the first float are upright.

Vacuum Resin Infusion.

In the year 2000 when I started to study the possibilities for a DIY boat building project, I was a total composite greenhorn, but I already had learned that a vacuum treatment was desirable to get the lightweight multihull quality I was looking for. However, it was hard to find any information about how to get a vacuum densified laminate within my range of possibilities.

I learned to understand the vacuum bagging technique but the implementation looks to be very challenging. At least to me. The fact that this technique should start with old-fashioned hand lay-up and then to be completed within the time constraints of the resin clock currently looks very discouraging to me. And for laminating and subsequent vacuum bagging the hulls are many helpers needed for which I do not have enough space in my humble workshop.

An article in our local ″ Zeilen ″ magazine put me on the trail of the vacuum infusion technique. This has given me a whole new perspective on the matter. Although, there was almost no information available, except that it was some kind of black magic, operated behind closed doors by some very professional boat building plants.

A breakthrough was made possible through the purchase of knowledge at Polyworx in the person of Mr. Arjen Korevaar.

With almost no previous composite experience, I suddenly saw the possibilities to make my boat building project possible and still be assured of the best possible quality. After all, vacuum infusion is a defined process that not depends of my initially lack on knowledge and experience and skills for laminating big boat hulls. It gave a boost to the preparations.

Earlier in the eighties I have built an epoxy/wooden boat, somewhere in a remote barn. From that I learned that I will never build a boat again in a different location than at home.

In the past I did a rebuilding of the garage of our modest house with the intention to enlarge the living room with the aft part of the (former) garage. But I had also a hidden motive to built a new boat, so the actual joining with the living room had still to wait some time ....

Building at home is essential for me. Despite the small room for this project, it is much more efficient than a workshop somewhere else. It's save, I can leave the things behind me and every single moment of the day, or when I feel like to do something, the project is just a few steps away. But the most important advantage is the fact I can stay at home and near my family, a great benefit to family- and social live.

With extension the working area is about 13 x 3,7 m², but the height is not enough to join the two main hull halves together. So I have to do this somewhere else.

Since there is only just enough room for the main hull (or halves), I made an attic floor for workbench and vacuum table. In fact, the whole floor is a 3,5 x 3,7 m² bench and a standing room is 0,9m. lower in front of this (removable). With the main hull in place, I don't need this lower floor anymore as working at the bench is possible while standing on the F-39 cabin roof.

However, I still need to learn to have the discipline to be very organized and clear, to be able to manage this job in this limited space. Anyway, I don't have a choice. I would never attempt such a project in another location than at home.

As I am going to build with epoxy, there is no inconvenience with bad smell because epoxy is almost odorless. Which is not the case with the two part painting products. These have an awful smell and for this reason I installed a big ventilation unit capable to maintain a low pressure in the workshop. With this the painting fumes flow outside instead of causing troubles with the family.

Workshop extension

There was still one difficulty to overcome: the garage is 2m. too short so I had to enlarge the garage a bit. This turned out to be a big problem in our highly civilized and urbanized small country! July 2001 the plans for a temporary extension were sent to the officials of the my hometown.

By the end of August they decided to turn my request down...............

As I've said before, home building is essential. No permit is no project, but this is something the Jacks-in-office didn't want to know and certainly would never understand. (and here they are right, it's nuts probably ;-)

Wow, I never expected this. The extension is simply, small and temporal while I knew (almost) for sure the Dutch building laws must allow this! So next step was to raise an objection to this decision and for this we have a special committee of independent wise men. They decided that the refusal was taken on wrong arguments and advised the officials to think about other arguments for a refusal (no sailors neither)!

Now it became a bad joke. Better arguments were hard to find, but they found them, legal ones against a temporary extension, but, as I found out, nothing against a permanent extension...........

All parties were agreed that this enlargement is not an embellishment for the house, so the legal permanent option is the worst solution. This strange situation came to an climax by a special permission by the Lord Mayor himself, which allowed me to build the temporary (and inexpensive) option. I received this long awaited document in the summer of 2002.

After one year of struggle, the actual building of the workshop extension was finished in just 3 weekends. Even the neighbors like the result and are getting curious about my activities (which are quite abstract for non-yachties).

I started the building of the F-39 in the Spring of 2003 at home. By the end of 2009 I have build and finished both floats as well as the starboard half of the main hull together with some interior parts as settee and galley. Roughly a little less than half of the entire construction job, although it has taken much too long.

But then that once-in-a-lifetime opportunity came along ....

2010 Changes, another workshop