ONE, HMM And Yang Ming Confirm The Alliance Partnership

ICS Publications Announces The Launch Of “A Practical Guide To Shipboard Inspections”

‘Helios’ Sets New Guinness World Record For Most Solar Panels On A Cargo Vessel

Shipowners Who Force Seafarers To Sail High-Risk Areas May Face Sanctions

Introduction To Ship Load Lines

If we try to define Load Line in the simplest fashion, it will be as follows:

“Load line is a special marking positioned amidships which depicts the draft of the vessel and the maximum permitted limit in distinct types of waters to which the ship can be loaded.” When the load line is drawn over the output characteristic curve in a graph, it makes contact at a point known as the operating point/ quiescent point or Q-point.

As a result of the numerous maritime accidents that have happened at sea due to the overloading of vessels, the significance of having a standard maximum limit for ships was identified long before. However, it took many years to have an International agreement for the universal application of Load lines.

It was in 1930 when the first International Load Line Convention took place, after which it was periodically amended until the latest one in 2003.

To make a complete comprehension of Load Lines, we must address the following questions:-

- What is the purpose of Load Line?

- Why is it necessary for ships to have Load Lines?

- What exactly is a Load Line?

- What is the marking on a Load line?

- What are the different types of Load Lines?

Table of Contents

Purpose and Necessity of Load Lines

The Load Line concept emerged in Britain in the 1870s to prevent merchant ships from being overloaded. The fundamental purpose of a Load Line is to allow a maximum legal limit up to which a ship can be loaded by cargo. By prescribing such limits, the risk of having the vessel sailing with inadequate freeboard and buoyancy can be limited.

A vessel should have sufficient freeboard at all times. Any exceptions will result in insufficient stability and excessive stress on the ship’s hull. This is where load-lines play an essential role, detecting whether the vessel is overloaded and its freeboard tremendously effortless.

Lloyd’s Register has established a minimum freeboard requirement for its classed ships to ensure their good reserve buoyancy in heavy seas.

However, since the buoyancy and immersion of the vessel largely depend on the type of water and its density, it is not practical to define a standard freeboard limit for the ship at all times. For this reason, the load line convention has put regulations that divide the world into different geographical zones, each having a separate prescribed load line.

For example, A vessel sailing in Winter on North Atlantic Ocean will have a greater freeboard than on a voyage in Tropical Zones and Freshwaters.

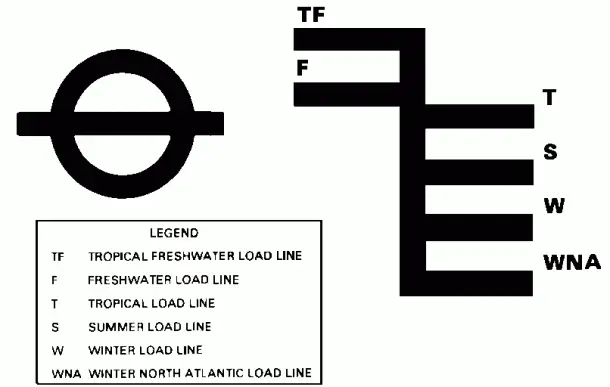

Understanding Load Line Marks And Types

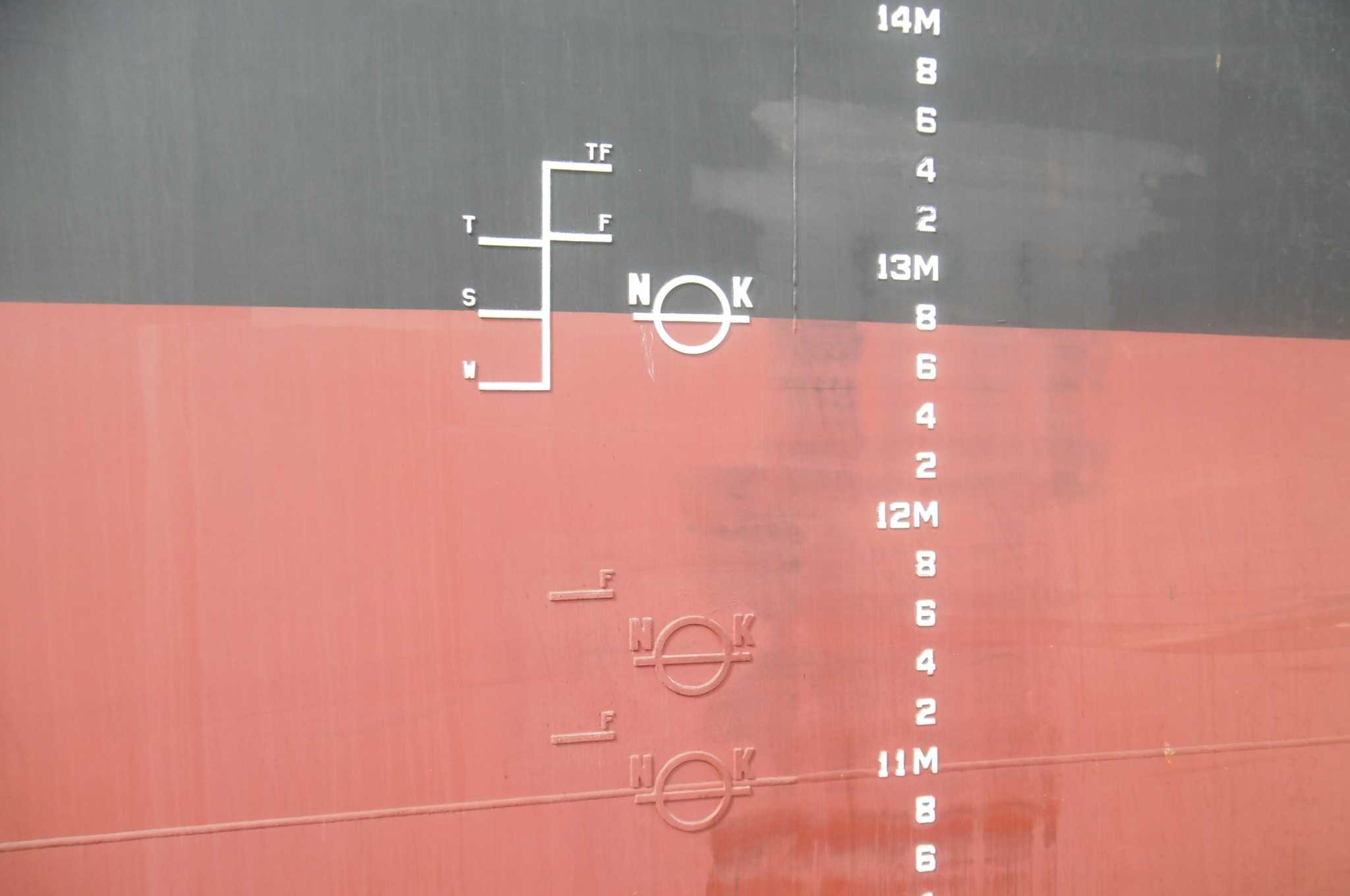

As we have already defined above, the Load Line is a special marking positioned amidships. All vessels of 24 meters and more are required to have this Load line marking at the centre position of the length of the summer load waterline.

- Standard Load Line marking – This applies to all types of vessels .

- Timber Load Line Markings – This applies to vessels carrying timber cargo .

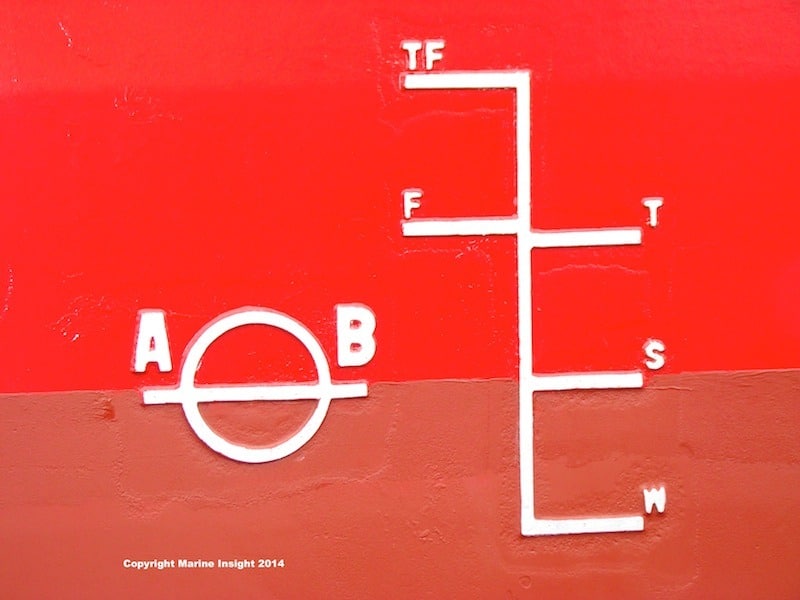

These marks shall be punched on the hull’s surface, making it visible even if the paint on the side of the ship fades out. The marks shall again be painted white or yellow on a dark background/black on a light background. The complete Load line markings consist of 3 vital parts.

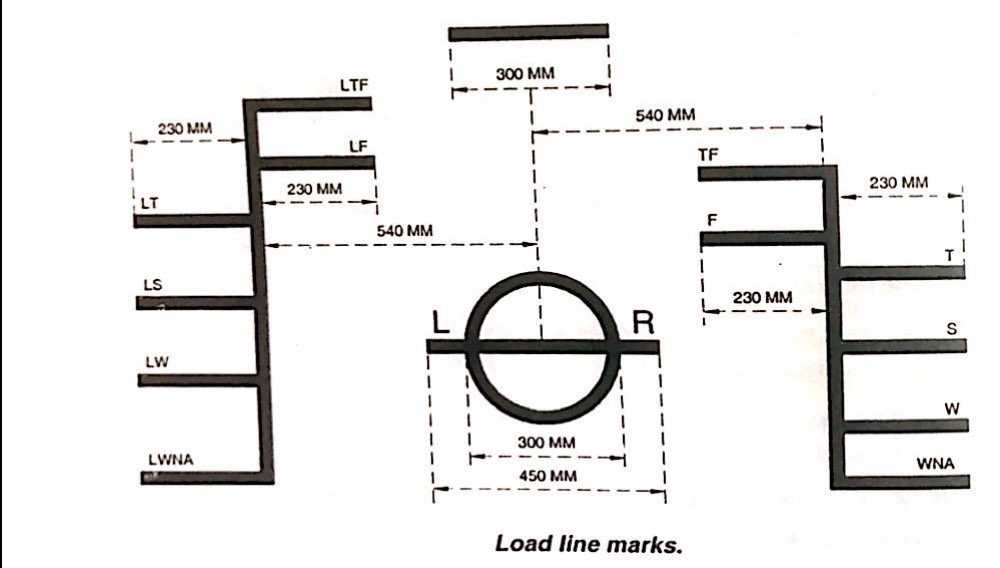

- Deck Line is a horizontal line measuring 300mm by 25mm. It passes through the upper surface of the freeboard.

- Load Line Disc is a 300mm diameter and 25mm thick round-shaped disc. A horizontal line intersects it. The upper edge of the horizontal line marks the ‘Summer saltwater line’, also known as the ‘ Plimsol Line.

- Load Lines – Load lines are horizontal lines are extending forward and aft from a vertical line placed at a distance of 540mm from the centre of the disc. They measure 230mm by 23mm. The upper surfaces of the load lines indicate the maximum depths to which the ships may be submerged in different seasons and circumstances.

S – Summer:- It is the primary freeboard line at the same level as the Plimsoll Line. Other load lines are marked based on this Summer freeboard line.

T – Tropical:- It is 1/48 th of the summer draft marked above the Summer load line.

W – Winter:- It is 1/48 th of the summer draft marked below the Summer load line.

WNA – Winter North Atlantic:- It is marked 50mm below the Winter load line. It applies to voyages in North Atlantic ( above 36 degrees of latitude) during the winter months.

F – Fresh Water:- It is the summer freshwater load line. The distance between S and F is the Fresh Water Allowance (FWA).

TF – Tropical Fresh Water is the freshwater load line in Tropical. It is marked above the T at an amount equal to FWA.

Watch the video explaining the Plimsoll line on the ship

Timber Load Line Markings

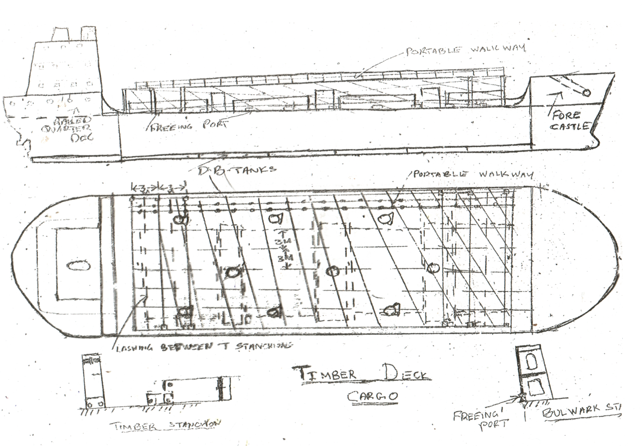

Ships engaged in the timber deck cargo trade must have a unique set of Load lines known as the Timber Load Lines. Such vessels shall comply with the Code of Safe Practices for Ships Carrying Timber Deck Cargo in construction and other requirements obtaining greater reserve buoyancy and lesser summer freeboard.

Timber cargo vessels will have a second set of Load Lines marked like the standard load lines positioned 540mm above the centre loading disc.

The timber load line’s letter marking is different and prefixed by ‘L’, meaning ‘Lumber’.

LS – Lumber Summer:- Its upper edge marks the summer saltwater timber loading. It is situated at a specified level above the Plimsol line.

LW – Lumber Winter:- It is 1/36 th of the lumber summer draft below LS.

LT – Lumber Tropical:- It is 1/48 th of the lumber summer draft above LS.

LWNA – Lumber Winter North Atlantic:- It is at the same level as WNA.

LF – Lumber Freshwater:- It is situated above the LS by an amount equal to FWA.

LTF – Lumber Tropical Fresh Water:- It is positioned above LT by an amount equal to FWA.

International Loadline Certification

Every ship surveyed and marked in accordance with the present Load line convention is issued an International Load Line Certificate by the authorised administration. The certificate will have a validity of not more than five years and will contain all vital information, including the assigned freeboard and freshwater allowance.

It is to be noted that, after completion of a load line survey and issuance of the certificate, no changes shall be made to the superstructure, markings, equipment or arrangements covered under the survey. If such changes need to be made, the survey’s authorised authority shall be contacted.

Over to you.

Please go ahead if you have more points to mention on ship load-lines. We would like to see them as comments!

Frequently Asked Questions

1. what is a load line in shipping.

Also known as the Plimsoll Line, the Load Line is a marking that indicates the extent to which the weight of a load may safely submerge a vessel, by way of a waterline limit.

2. Where is the purpose of a load line on a ship?

They are horizontal lines extending forward and aft from a vertical line situated at a distance of 540 mm from the centre of a disc. They measure 230 mm by 23 mm. The upper surface of these lines indicates the maximum depths to which vessels can be submerged in different situations and seasons.

3. What is a summer load line?

It is the waterline up to which a ship may be loaded in seas during summers when waves are lower and less harsh than in winters.

4. Where are load lines exactly located?

It is said that a commercial carrier is adequately loaded when its waterline is equal to the plimsoll line which is located on the hull of a ship.

5. How many types of load lines are there?

There are two types of load line markings. The standard load line marking is applicable to all vessels and the Timber load line markings are for ships carrying timber.

You might also like to read

- 15 Important Points To Consider While Preparing For Load Line Survey On Ships

- Loads Acting On Fore And Aft Regions Of Ships – Strengthening Against Dynamic Loading

- What Are Line Throwing Apparatus On Ships?

- Real Incident On Ship: Oil Cargo Spill From Tank Washing Line Drain Cock

- What is Plimsoll Line on Ships?

Article In Pictures

Disclaimer : The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

BE THE FIRST TO COMMENT

70 comments.

WHAT DOES THAT CIRCLE INDICATES IN THAT LOADLINES?

@ suamil Thanki:

The Circle in the loadline has two significance:

1. The circle with the line through it indicates whether or not the cargo is loaded evenly

2. In earlier days, the line in the circle was taken as a reference for maximum draught of the ship, which is now same as summer load line of the ship.

The circle is the load line disc and the letters on either of its side is simply the abbreviation of the classification society which has done the survey and issued the certificate. In the above image ‘AB’ is the abbreviation of ABS Classification Society.

Please read above the Load Line subtitle.

Well done fellow seaman. Bon voyage

@Sunil: Please post all your queries in our forum- https://forums.marineinsight.com

LOAD LINES ALSO IMPLY WATERTIGHT OF HATCHCOVERS, HATCHES, PIPES, BLOWERS, ETC

Just to correct you,

1) Stress & stability problems do not result from overloading. You might be loaded above the required load line marks but still have good GM and stresses well within limits and you might be half way from load line marks and still have unacceptable stresses. The purpose of load lines is to ensure vessel has sufficient reserve buoyancy (and not stress and stability).

2) The load lines zones are not divided on the basis of type of water & density (as claimed in this post) but on the basis of weather conditions in that geographical area that warrants the ships to be loaded lower (which is Winter Loadline) or above (which is Tropical loadline) summer loadline. Fresh water marks are given to give the indication of loading in fresh water so that when the vessel arrives at sea, she is at her allowed loadline.

Considering the rank of the author, Well Done.

Your inputs are well noted and the corrections are highly appreciated.

it’s answers my question..i help load/unload ships for seaboard/jacintiport, Houston…always wondered what the marks were for…

How many classification societies do we have?please name them.

If sea water density more or less remains same, then why ships draft reduces in winter north atlantic..ie how seasons causes draft changesss…

Classification Societies…

ABS – American Bureau of Shipping (USA) *Largest BV – Bureau Veritas (France) CCS – China Classification Society (China) DNV – Det Norske Veritas (Norway) GL – Germanischer Lloyd (Germany) IRS – Indian Register of Shipping (India) KRS – Korean Register of Shipping (Korea) LR – Lloyd’s Register of Shipping (UK) *Oldest NK – Nippon Kaiji Kyokai (Japan) RINA – Registro Italiano Navale (Italy) RS – Russian Maritime Register (Russia) CRS – Croation Register of Shipping (Croatia)

.In determining load line zones , both weather and density factors are included or on weather ?

.In determining load line zones , both weather and density factors are included or only weather ?

What is the difference between standard loadline and timber loadline???

timber loadline is assigned for ship carrying timber cargo on deck and standard loadline is for any type of ship.

Why there are two loadline certificates issued and only one used at a time??

Gd day to all

Pls clear my doubt why tropical is 1/48 . Thks Best regards.

The first illustrating diagram hand an error in the thickness value it should be 25 mm not 23 mm. Plimsol was a real good blissed person he was a cause to save other seafarers life from sinking at heavy weather sea.

Why would some would like to have a multiple load line certificate?

Hi friend I am shashank junior Engg I want to know why load line given at mid ship only

In addition, The WNA applies only to vessels less than or equal to 100 meters in length. Thank you.

Any one can tell me the meaning of the following abreviation SEP in maritime methodology Thanks a lot

what is the difference between plimsol mark and fresh water load line ?

please clear my doubt. if i load from winter seasonal zone what loadline shld. be follow the winter load line. or the summer load line ? is there any specific density for TF, F, T, S, W, WNA? What thats mean of 1/48 from summer to tropical / and winter?

Hi jack says, If you load cargo in winter seasonal zone, you have to load just to winter load line. This means your appropriate load line must be always above the water level in all seasonal zones throughout your voyage, thanks

What is minium summer load line

Eddie, that differs per ship

Hi, please clear my doubt, If vsl load in the tropical seasonal zone and discharge in the winter zone which load line need to use in the loading port.

why load line marking has standard dimension ?

on what criteria the loadline is detrmine for a particular vessel

A LOAD LINE CONDITIONS OF ASSIGNMENT SURVEY will be performed by the surveyor with following important criteria: Freeboard, Stability, Ship type, deck openings, watertightness arrangement etc.

why this figure 1/48 cmae,why not any other figure?

can you explain three conditions of load line law that would prevent a vessel proceeding to sea

Is there any derivation for 1/48….or just a rough number for density correction?

Hi dears Could you help me to find stability of Mr.Lester with solution way ?

can you explain how the draft marks 2, 4, 6….are read??? say suppose the waterline is just touching 2 then should we consider it as 2m or the 2 should be completely immersed to take as 2m

@Vamsi: 2 should be immersed to take the reading as 2.

please clear my doubt, If vsl load in the tropical seasonal zone and discharge in the summer zone which load line need to use in the loading port.

do winter loadline apply in australia

Hay Point is in the Tropical Load Line Zone. The area outside the Great Barrier Reef is in the South Pacific Seasonal Tropical Zone. Tropical: From 1 April to 30 November; Summer: From 1 December to 31 March.

How does a ship superintendent relate their job scope to load lines regulations during site duties?

Why do some cargo ships have more than one set of load lines marked, i. e. multiple load line.

@Hai: Multiple load lines are used when, for a period of time, a FG cargo ship has a need to operate temporarily with a greater freeboard than the minimum freeboard stipulated in accordance with the International Convention on Load Lines. IN Many ports, the port dues are calculated as per the deadweight of the ship and some ports have a restriction on maximum deadweight of the ship. with multiple ladling, the owners can reduce or increase the deadweight according to their requirement.

please help me this ques come on mca writen exam i couldn’t fiend the ans **explain the importance of EACH of the following with reference to the purpose of the load line survey. 1.bilge system 2.ballast system

Sir pls clear my doubt on these question when we can add 0.025 either water lineabove or below summer draft and wats the difference betwwen intial and present draft

How you calculate the height of loadline location?

Purpose of the disc in load line

@Capt. Madhu incorrect, the 2 should be on the waterline to take the reading as 2M

Can I load the vessel and exceed summer draft when I am in summer Zone. In example, my mean draft , amidship is 16,5, summer draft16,9, aft 17,1 fwd 16,1. In this scenario i have exceeded summer draft the stern, but at the plimsol mark, midhsip is not exceeded. Correct If I am wrong, but to fulfill the requirements the mean draft must not exceed the summer draft ?

How to check if the loadline is ad per the certificate? Procedure please ….

Which load line you use in the month of July ( you are proceeding from IRAN to WEST coast of INDIA)

Why vessel less than 100 m are assigned to wna load line wile trading in winter in atlntic area

@Radek As per the LL convention, the ship cannot be submerged at the appropriate load line, in still water, at a density of 1.025kg/l. It is legal to load the ship to the load line and have stern trim.

@anscar Whatever zone the ship is sailing in is the loadline that the ship cannot exceed. You can exceed the summer draft in a tropical zone, consume fresh water and fuel oil to reduce the draft before you get to the summer zone.

Sir, please clear my doubt. Why timber Loadline is higher than the standard Loadline?

Which nautical publication will you find the load line zoning chart?

Hello, may I ask permission to use an image from this article. It is the image of the load line near the top of this page with credit Marine Insight. I would like to use this image in a children’s educational book called Extreme Science: Forces in a section explaining how ships float. It would be used very small, thumbnail-sized on an inside page.

Many thanks

@Rob: You can use the image, provided; due credits are given to the website.

Difference between star board load line and Port load line marking

Please what is all seasons load line, and how will implement it.

@Abdel Naseer: In the case of a ship being assigned a freeboard greater than minimum so that the load line mark is marked at a position corresponding to or lower than the lowest seasonal load, and line assigned at a minimum freeboard is in accordance with the calculation procedure, only the Fresh Water Load Line needs to be marked. Such load lines are termed “All Seasons Load Lines” and are illustrated in the photo.

I was reading the Wiki article on this subject, and the first image there has a Plimsoll line marked with a “C.” What does that mean. You can see it here: https://commons.wikimedia.org/wiki/File:733_how-deep.jpg

@Spencer hello. i have got two question about this all season load line Q1,If only Fresh Water Load Line need be marked, ships navigate in Tropical Fresh Water Area will bear a loss of freeboard by d/48. Are there any details can support to explain the reason of this amendment. Q2:Does the “lowest seasonal load line” includes the Winter Load Line?

Which ships need not to have a WNA mark?

Why load line is on both side of ship ?

Having the load line on both sides of the ship ensures that the ship’s draft can be easily and accurately determined from either side, regardless of the ship’s orientation or the position of the observer or stationing of the ship in port. Additionally, the load lines are also painted on both sides of the ship to meet the international maritime regulations, which requires ships to be marked with load lines in order to ensure that they are operated safely and to prevent overloading.

Having the load line on both sides of the ship ensures that the ship’s draft can be easily and accurately determined from either side, regardless of the ship’s orientation or the position of the observer or stationing of the ship in port. Additionally, the load lines are also painted on both sides of the ship to meet international maritime regulations, which require ships to be marked with load lines in order to ensure that they are operated safely and to prevent overloading.

Leave a Reply

Your email address will not be published. Required fields are marked *

Subscribe to Marine Insight Daily Newsletter

" * " indicates required fields

Marine Engineering

Marine Engine Air Compressor Marine Boiler Oily Water Separator Marine Electrical Ship Generator Ship Stabilizer

Nautical Science

Mooring Bridge Watchkeeping Ship Manoeuvring Nautical Charts Anchoring Nautical Equipment Shipboard Guidelines

Explore

Free Maritime eBooks Premium Maritime eBooks Marine Safety Financial Planning Marine Careers Maritime Law Ship Dry Dock

Shipping News Maritime Reports Videos Maritime Piracy Offshore Safety Of Life At Sea (SOLAS) MARPOL

WAIT! Did You Download 13 FREE Maritime eBooks?

Sign-up and download instantly!

We respect your privacy and take protecting it very seriously. No spam!

Knowledge Of Sea

We will keep you updated

LoadLine and Draft Marks

Loadlines are one of the earliest safety features introduced in shipping, At the time of introduction, ships were suffering heavy losses because of overloading. Lord Plimsoll, a member of the parliament, fought for introduction of Loadlines and hence the term “plimsoll disc”. The safety of the ship is of paramount importance and all your energy must be devoted in that direction. An overloaded ship is an unsafe ship, as it does not have adequate reserve buoyancy and strength to face the elements.

How, when and why loadline marks came into being

The origin of loadline marks dates back to 1876 when a member of the British parliament by the name of Samuel Plimsol took an active part in promoting the Merchant Shipping Act of 1876 (MSA). This act was the first legislation, which required all ships to carry loadline marks on each side of the vessel.

The Concept was to bring about shipboard safety for seafarers against the then greedy ship-owners that were interested only in maximising their profits by Constantly Overloading their ships, thereby jeopardising safety and life at sea.

The Load Line regulations of 1966 under the current Convention are in force now and deal with all details regarding the strength of the ship, sub-division, watertight closing devices and where needed weather tight closing appliances, load line marks and the assignment of freeboards.

The ship’s load line certificate is displayed on the ship and the master records the sailing draft and the freeboard in the official logbook. Heavy penalties and detention may be the result if a ship does not comply with the freeboard requirements and LL regulations.

Criteria for load line assignment

Load lines are assigned to ensure that the ship has sufficient freeboard to ride the seas in the prevailing weather conditions.

In such assignments, following conditions are taken into account:

- Adequate freeboard to provide reserve buoyancy even when the ship is rolling and pitching.

- Strength of the hull (ships are designed to submerge to a designed draft)

- The ability to shed seawater , off the decks. Ships are provided with either decks with only railing or bulwarks with freeing ports on the bulwarks. Ships also have decks with sheer, which rise in the fore and aft direction so that the water drains off. Ships also have a camber, which allows the water to drain off to the scuppers.

- Means of closing the number of openings on the main deck .

- The sub-division of the hull to ensure damage stability even when one or more compartments get flooded.

Location of deckline, the Plimsol disc and assigned freeboard.

The deckline is located amidships in line with the uppermost continuous plating (weather deck) where it meets the sheer strake (the upper most plate (strake) of the ship’s side).

In case you are on a ship with a ’rounded sheer strake, you will observe that the deck line is located lower down where the curvature of the sheer strake ends.

Various load line marks, dimensions and their location

On the side of the ship on both sides amidships, are marked a set of lines as shown in the figure. These are called LOAD LINES.

- Right at the top is the deck line. It is 300 mm long and 25 mm wide with its upper edge in line with the uppermost continuous watertight deck.

- Vertically below the deck line is a circle whose outside diameter is 300 mm. It is called the loadline disc, or Plimsoll.

- A horizontal line 450-mm long and 25 mm wide cuts through the loadline disc. it is called the Plimsol line. Its upper edge passes through the centre of the disc. The letters L and R are initials of the assigning authority – in this case Lloyds Register. These letters may sometimes be IR AB, BV or the initials of any other assigning authority. IR stands for Indian Register of Shipping. The height of these letters is 115 mm and their width is 75 mm. The gap between the Plimsol line and these letters are 38 mm in height.

- A set of lines each 230 mm long and 25 mm wide marked TF, F, T, S, N, WNA are marked 540 mm forward of the centre of the loadline disc. They are on the right of the disc on the starboard side and on the left side of the disc on the port side (i.e. forward of the Plimsoll mark).

Load line zones

The oceans are divided into various zones these consist of

Summer – S

Tropical – T

Winter – W

Winter north Atlantic – WNA

Fresh water – F

Tropical fresh – TF

Load line marks

In the figure above, you would notice two sets of toad lines. The one on the right the normal load line and one on the right hand include marks for a ship carrying lumber or timber on its deck. (Hence the prefix “L”)

Load lines and zones

Zones are marked as areas along with the dates of its applicability on a special chart called the LOADLINE ZONE chart. You will find this chart prominently displayed on the bridge and in the cargo office. A certain area could be summer zone during certain months and tropical or winter during the remaining months (see Zone chart on board your ship). These are called seasonal zones.

It is mandatory for a ship to ensure that at all time on its voyage that the appropriate load line is not submerged neither in port nor during any stage of the voyage nor when passing from one zone to the other.

- When a ship is in tropical zone and in seawater of density 1025, she must not load to more than the upper edge of the line marked T.

- When a ship is in summer zone and in the seawater of density 1025, she must not load to more than the upper edge of the line marked S. Incidentally, this line is at the same level as the line passing through the centre of the load line disc.

- When a ship is in winter zone and in seawater of density 1025, she must not load to more than the upper edge of the line marked W. .

- In the Winter North Atlantic the seas are so rough that smaller ships may not remain safe if allowed to load even upto SW”. The upper edge of WNA line, which is 50 mm below the `W” line, is the maximum they can load in waters of 1025 density. Ships of more than 100 meters length do not have this limitation.

- When the density of the water is 1000 i.e. in fresh water and In summer zone a ship may load upto the upper edge of the line marked ” F”

- When the density is 1,000 i.e. in fresh water and in tropical zone , a ship may load upto the upper edge of the line marked “TF”.

Distances between the seasonal load lines

- The distances between the centre of the disc and the deck line is prescribed by the assigning authority and depends on several factors including the ships dimensions, structure, water tightness arrangements, type of cargo to be carried etc. The draft at the S line is the summer load draft.

- The distance between W and S, between T and S and between and TF is the same and is equal to 1/48th of Summer load draft.

- The distance between S and F is equal to the distance between T and TF and is the Fresh water Allowances (FWA) for that ship.

Assigning authority of the loading marks

The Flag State of a vessel is the authority. In many cases, they hand over the inspection and assignment to the classification societies, who assign the marks and issue the certificate to the ship on behalf of the Flag State.

Reading load line marks

- The ring, lines and letters shall be painted in white or yellow on a dark background, or in black on a light background.

- They should be permanently marked on both sides.

- The marks should be plainly visible.

- All readings are taken from the top of the relevant load tine mark.

Knowledge and use of draft marks (Also spelt as draught marks)

- Draft marks on a ship are located at 6 locations.

- On both sides at the bow

- On both sides amidships

- On both sides at the stern

Draft marks could be either in meters or in feet or in both i.e. meters & feet.

Draft marks

Draft marks are numerals painted on the stem, amidships and stern of a ship. They indicate the depth of the ship’s keel below the water line.

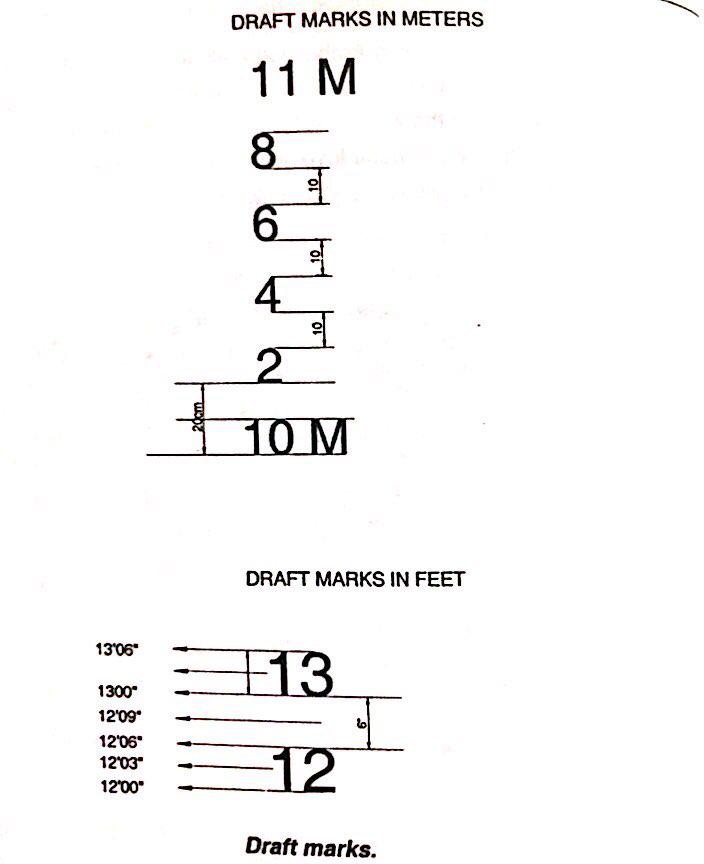

The meter mark numerals are 10cms high. in between the meter marks but slightly to the right of them are marked Arabic numerals as 2, 4, 6 and 8, this indicates 20cms, 40cms and 60cms and 80cms. The’ of these Arabic numerals is 10 cm and spacing between them is 10 cm. The bottom of the numeral indicates the draft.

If the water level touches the bottom of ’10’ the draft would be 10 meters if the water level just touches the bottom of 2 then the draft level would be 10 meters and 20 cms, if the water level just touches the top of ‘2’ then the draft would be 10 meters and 30cms. if the water is at any level other than the top or the bottom mark, the draft has to be estimated. The thickness of all marks is 1 cm.

The feet are marked either in Arabic numerals or in roman. In both cases, the height of the marks is 6 inches. if the water level just touches the bottom of 12, the draft would be 12 ft. If the water level just touches the top of 12 ft, the draft would be 12 feet 6 inches. If the water level were halfway between the top of 12 and bottom of 13, the draft would be 12 ft 9 inches: The thickness of the mark is one inch.

Draft Marks

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Load line and Draught Markings

Load Line Markings

The first official loading regulations are thought to date back to maritime legislation originating with the Kingdom of Crete in 2500 BC when vessels were required to pass loading and maintenance inspections. Roman sea regulations also contained similar regulations.

In the Middle Ages the Venetian Republic, the city of Genoa and the Hanseatic League required ships to show a load line. In the case of Venice this was a cross marked on the side of the ship and of Genoa three horizontal lines.

However over the centuries, greed took over and malpractises of overloading started around the world.

Coffin ships

Coffin ship is the name given to any ship that has been over-insured and is therefore worth more to its owners sunk than afloat. These were hazardous places to work in the days before effective maritime safety regulation. They were generally eliminated in the 1870s with the success of reforms championed by British MP Samuel Plimsoll.

Lord Plimsoll

Many of these in the days of wooden sailing ships were old ships riddled with wood rot, woodworm and shipworm, repainted, renamed and falsely stated to be new ships. There were over 2000 cases of sailors who had signed on as crew for a ship, saw the ship’s condition and refused to go on board it. They were tried in court for this refusal. Samuel Plimsoll took up this issue.

Samuel Plimsoll (10 February 1824 – 3 June 1898) was an English politician and social reformer, now best remembered for having devised the Plimsoll line (a line on a ship’s hull indicating the maximum safe draft, and therefore the minimum freeboard for the vessel in various operating conditions).

In 1867, Plimsoll was elected as the Liberal Member of Parliament for Derby, and endeavored in vain to pass a bill dealing with the subject of a safe load line on ships. The main problem was the number of ship-owning MP’s in Parliament.

In 1872, he published a work entitled Our Seamen, which became well known throughout the country. Accordingly, on Plimsoll’s motion in 1873, a Royal Commission was appointed and in 1875 a government bill was introduced, which Plimsoll, though regarding it as inadequate, resolved to accept. Attempts were made by the Prime Minister to drop the bill. However popular feeling forced the government to pass a bill which in the following year was amended into the Merchant Shipping Act.

This gave stringent powers of inspection to the Board of Trade and the mark that indicates the safe limit to which a ship may be loaded became generally known as Plimsoll’s mark or line.

The waterline is the line where the hull of a ship meets the surface of the water, in concept or reality. Specifically, it is also the name of a special marking, also known as an international load line, Plimsoll line and water line (positioned amidships), that indicates the draft of the ship and the legal limit to which a ship may be loaded for specific water types in order to safely maintain buoyancy, particularly with regard to the hazard of waves that may arise.

The purpose of a load line is to ensure that a ship has sufficient freeboard (the height from the water line to the main deck) and thus sufficient reserve buoyancy. The freeboard of commercial vessels is measured between the lowest point of the uppermost continuous deck at side and the waterline and this must not be less than the freeboard marked on the load line certificate issued to that ship. All commercial ships, other than in exceptional circumstances, have a load line symbol painted amidships on each side of the ship. This symbol is also permanently marked, so that if the paint wears off it remains visible. The load line makes it easy for anyone to determine if a ship has been overloaded. The exact location of the load line is calculated and verified by a classification society and that society issues the relevant certificates.

As we have already defined above, Load Line is a special marking positioned amidships. All vessels of 24 meters and more are required to have this Load line marking at the centre position of the length of summer load water line.

There are two types of Load line markings:-

Standard Load Line marking s – This is applicable to all types of vessels.

Timber Load Line Markings – This is applicable to vessels carrying timber cargo according to regulations.

These marks embossed on the surface of the hull making it visible even if the ship side paint fades out. The marks shall again be painted with white or yellow colour on a dark background / black on a light background.

The complete Load line markings consist of 3 vital parts.

Deck Line – It is a horizontal line measuring 300mm by 25mm. It passes through the upper surface of the freeboard.

Load Line Disc – It is 300mm diameter and 25mm thick round shaped disc. It is intersected by a horizontal line. The upper edge of the horizontal line marks the ‘Summer salt water line’ also known as ‘Plimsoll Line’.

Load Lines – Load lines are horizontal lines extending forward and aft from a vertical line placed at a distance of 540mm from the centre of the disc. They measure 230mm by 25mm. The upper surfaces of the load lines indicate the maximum depths to which the ships maybe submerged in different seasons and circumstances. On most ships, you find paint colour changing at Summer mark.

This is how it is seen on the Starboard side of shipside.

T – Tropical :- It is 1/48th of summer draft marked above the Summer load line.

W – Winter :- It is 1/48th of summer draft marked below the Summer load line.

WNA – Winter North Atlantic :- It is marked 50mm below the Winter load line. It applies to voyages in North Atlantic ( above 36 degrees of latitude) during winter months. Ship’s length not exceeding 100 m.

F – Fresh Water :- It is the summer fresh water load line. The distance between S and F is the Fresh Water Allowance (FWA)mm = Displ / (4 x TPC).

TF – Tropical Fresh Water :- It is the fresh water load line in Tropical. It is marked above the T at an amount equal to FWA

Add Load line zones explanation and chart

Load Line Zones

They are Seasonal.

The seasonal zones, areas and periods that determine the appropriate load line in a particular sea area at a given time of the year are by way of the chart

The Tropical, Summer and Winter freeboard zones are based upon the following weather criteria:

Summer zones : Regions where not more than 10% of wind speeds exceed force 8 Beaufort (34 Knots)

Tropical Zones : Regions where not more than 1% of wind speeds exceed force 8 Beaufort (34 knots) and not more than one tropical storm in a ten-year period occurs in an area of 5 0 Latitude/Longitude square in any one separate calendar month.

Winter Zones – Are all other regions

Draft Marks

What are draft marks? Why do you need them?

All the ships have draft marks in the forward, aft and midship region on port and Starboard sides . These marks are used to verify the draft of the ship in any loading condition. In simpler words draft mark tells us what is the ships depth at that time. It is distance from the Waterline to the lowest part of the ship.

Draft readings when used for calculations give us underwater volume and Displacement. This helps in knowing cargo quantity on board.

Draft also tells us about minimum depth requirements for ship to stay afloat.

How do you read Load lines and Draft marks?

LOAD LINES: They are marked only Amidships on both sides. Upper edge of the load line indicates correct reading. We do not measure anything on Load Line markings. We just have reading of Yes/No. Load lines deal with FREEBOARD only and NOT DRAFT.

DRAFT MARKS: They are marked on both sides, Forward, Mid-ship and Aft. Readings are taken on both sides and averaged.

When the markings are in meters, the main meter marks are marked as numbers followed by the letter M such as 8M, 9M, 10M. In between the metric marks are numeral markings such as 2, 4, 6 and 8 to indicate 20 cm, 40cm, 60 cm and 80 cm. The height of each mark is 10 cm and the distance between the mark in 10 cm.

If the water is just in line with the LOWER EDGE of the mark 10M, the draft is 10.0 meters. If the water is in line with the top edge of 10 M, then the draft is 10.10 meters and so on.

You must be logged in to post a comment.

- Marine Expert

- 0 5 952

Ship Load Lines

International Loadline Certification.

Every ship surveyed and marked in accordance with the present Load line convention is issued an International Load Line Certificate by the authorized administration. The certificate will have a validity of not more than five years and will contain all vital information, including the assigned freeboard and freshwater allowance.

After completion of a load line survey and issuance of the certificate, no changes shall be made to the superstructure, markings, equipment or arrangements covered under the survey. If such changes need to be made, the survey’s authorized authority shall be contacted.

Load line is a special marking positioned amidships which depicts the draft of the vessel and the maximum permitted limit in distinct types of waters to which the ship can be loaded.” When the load line is drawn over the output characteristic curve in a graph, it makes contact at a point known as the operating point/ quiescent point or Q-point.

As a result of the numerous maritime accidents that have happened at sea due to the overloading of vessels, the significance of having a standard maximum limit for ships was identified long before.

Purpose and Necessity of Load Lines.

The Load Line concept emerged to prevent merchant ships from being overloaded. The fundamental purpose of a Load Line is to allow a maximum legal limit up to which a ship can be loaded by cargo.

A vessel should have sufficient freeboard at all times. Any exceptions will result in insufficient stability and excessive stress on the ship’s hull. This is where load-lines play an essential role, detecting whether the vessel is overloaded and its freeboard tremendously effortless.

However, since the buoyancy and immersion of the vessel largely depend on the type of water and its density, it is not practical to define a standard freeboard limit for the ship at all times. For this reason, the load line convention has put regulations that divide the world into different geographical zones, each having a separate prescribed load line.

Understanding Load Line Marks And Types.

The Load Line is a special marking positioned amidships. All vessels of 24 meters and more are required to have this Load line marking at the centre position of the length of the summer load waterline.

Standard Load Line marking – This applies to all types of vessels.

Timber Load Line Markings – This applies to vessels carrying timber cargo.

These marks shall be punched on the hull’s surface, making it visible even if the paint on the side of the ship fades out. The marks shall again be painted white or yellow on a dark background/black or on a light background. The complete Load line markings consist of 3 vital parts.

- Deck Line is a horizontal line measuring 300mm by 25mm. It passes through the upper surface of the freeboard.

- Load Line Disc is a 300mm diameter and 25mm thick round-shaped disc. A horizontal line intersects it. The upper edge of the horizontal line marks the ‘Summer saltwater line’, also known as the ‘Plimsol Line.

- Load Lines – Load lines are horizontal lines are extending forward and aft from a vertical line placed at a distance of 540mm from the centre of the disc. They measure 230mm by 23mm. The upper surfaces of the load lines indicate the maximum depths to which the ships may be submerged in different seasons and circumstances.

S – Summer : - the primary freeboard line at the same level as the Plimsoll Line. Other load lines are marked based on this Summer freeboard line.

T – Tropical : - 1/48th of the summer draft marked above the Summer load line.

W – Winter : - 1/48th of the summer draft marked below the Summer load line.

WNA – Winter North Atlantic : - marked 50mm below the Winter load line. It applies to voyages in North Atlantic (above 36 degrees of latitude) during the winter months.

F – Fresh Water : - the summer freshwater load line. The distance between S and F is the Fresh Water Allowance (FWA).

TF – Tropical Fresh Water is the freshwater load line in Tropical. It is marked above the T at an amount equal to FWA.

Only registered users can comment

- Project Management – Dry Docking and Repairs

- Ship Services

- Marine CAD Services

- Marine IT Services

- Academic services

- MEO Class 1

- MEO Class 2

- MEO Class 4

- ASM / Masters

- Class IV Level

- Academic Papers

- Year/Month Sets

- Shirts & Trousers

- Deck Officers

- Engineer Officers

- Coveralls / Boiler Suits

- Marine Uniform Shirts & Trousers

- Epaulettes for Marine Deck Officers

- Epaulettes for Marine Engineer Officers

- Marine Belts | Peak cap | Accessories

- Marine Accessories

- Marine Engineering – General

- Marine Engineering – Motor

- Marine Electro Technology

- Ship Safety & Naval Architecture

- MMD Procedures

- Merchant Navy Courses

Load Line Regulations – A comprehensive guide

Load Line Regulations

Introduction.

The Load line regulations have a long history of over 140 years. They were introduced in the British parliament by Lord Plimsoll, in the year 1854 and finally passed in 1876 as the first merchant shipping Act. As per this Act all Merchant ships were required to have a Load line marked on the ship side at the mid-ship length. This Load line mark has a circle with a diametrical line cut across the circle . This mark is also known as plimsoll mark and ships were allowed to load only till this line reached the waterline, thus preventing overloading of the ship. The rule adopted to determine this line was by referring to a table of Freeboards against length of ship and from it determine the allowable Freeboard. This Rule is still in force even in India for assigning Load line to sailing vessels.

With the advent of steel ships and powered propulsion, the very simple Load line regulations has slowly developed into a more elaborate set of rules covering all known aspects of flooding and damage control. The 1930 Load line regulations came into force after the development of steel ships powered by steam or I.C. engines . At That time tankers were also in vogue . The rules therefore catered to dry cargo ships as well as tankers and the concept of two separate tables of Freeboards based on length of ship was in existence then as it is now. Most of the rules now in force were also in force then.

The 1966 Load Line Convention happens to be the first International Load Line Convention after IMO (IMCO) came into existence. The Convention was held from third March to fifth April 1966 . The L/L Regulations being the outcome of this Convention was adopted on fifth April 1966. The Regulations came into force six months after it was officially adopted ie on fifth October 1966.

The special provisions in these regulations is the official recognition given to steel hatch covers and an incentive to adopt steel hatch covers instead of wooden hatch covers. By favouring ships with steel hatch covers by a reduction in summer Freeboard., thereby increasing their dead weight capacity . Hence in these regulations there are actually three sets of basing summer Freeboards. Table A for liquid bulk carriers (tankers) , Table B for dry cargo carriers with steel hatch covers and a third Table showing the increase in Freeboard from Table B for ships fitted with wooden Hatch covers.

Another important feature in these regulations is the assignment of timber Load line to ships specially equipped to carry timber as deck cargo..Considering that timber is a buoyant cargo special regulations have been provided for carriage of timber deck cargo and conditions for its assignment. These are stated in chapter 4 of the Regulations.

The various chapters of these Regulations and their contents are shown in the following table:

| 1 | GENERAL | from 1 to 9 |

| 2 | CONDITIONS OF ASSIGNMENT | from 10 to 26 |

| 3 | FREEBOARDS | from 27 to 40 |

| 4 | SPECIAL REQUIREMENTS FOR SHIPS ASSIGNED TIMBER FREEBOARDS | from 41 to 45 |

| ANNEX 2 | Zones, Areas and Seasonal periods | |

| ANNEX 3 | CERTIFICATES |

OBJECTIVES OF ASSIGNING A LOAD LINE WITH FREEBOARDS

The goal objectives for assigning a load line to ships are twofold :

- To provide adequate reserve buoyancy against accidental flooding of any water-tight compartment in the

- To give protection to the crew on board for their safe movement within the

These goal objectives are realised by the following functional objectives, which are:

- Weather tight integrity of the freeboard or main deck

- Providing sufficient subdivision within the hull so that reserve buoyancy is sufficiently

- To provide adequate strength to the

- To provide comfortable and safe accommodation for the crew and facilities for their safe movement within the ship and to land ashore during port stay.

DIFFERENT FREEBOARD TABLES

The regulations provide primarily two separate tables, one for dry cargo vessels and another for liquid cargo vessels. From the tables one can observe that the basic freeboard for a tanker is considerably less than the freeboard of a dry cargo vessel of same dimensions. The reasons are as follows:

- Weather-tight integrity of freeboard deck : – The tanker has small openings for cargo ullaging and tank entry on the freeboard deck, which can be efficiently maintained in tight condition as compared to the dry cargo carrier which has large hatch covers for the holds which are rather difficult to maintain in a weather tight

- Cargo space subdivision :- Considering two equally dimensioned ships , one a tanker and the other a dry cargo vessel, the tanker has its cargo space divided into 3*5=15 tanks by transverse and longitudinal bulkheads, whereas the dry cargo vessel’s cargo space is divided into 5 holds by transverse bulkheads. The reserve buoyancy potential for the tanker becomes superior to the dry cargo vessel’s reserve

- Hull strength :- The tanker hull strength is superior to the dry cargo ship strength of same The longitudinal bulkheads and Isherwood framing system improve considerably the resistance to overcome large bending moments the tanker is subjected to. The large web frames within the tanker assist the tanker to resist the large shear forces the tanker is subjected to. This aspect makes the tanker more stronger than the dry cargo ship of equal dimensions.

- Permeability ;- In a tanker because of the liquid nature of the cargo which fills up the cargo space to its full level, the permeability of sea water entering the cargo space due to bilging is very negligible as compared to a dry cargo vessel whose permeability of the cargo space is about 60% on an average

Taking into account all the above factors all of which are in favour of the tanker, the regulations provide for a considerable difference in the freeboards of these vessels.

SUMMARY OF THE REGULATIONS

1Strength of hullShips built and maintained in accordance with class regulations are considered to have adequate strength.10Information to be supplied to the masterThe need to provide a ship specific approved stability booklet with relevant damage stability calculations for masters use. Where D is less than L/15 no reduction in freeboard.

| Chapter | Reg no. | Title | Objective and brief summary |

| 1 | Strength of hull | Ships built and maintained in accordance with class regulations are considered to have adequate strength. | |

| 2 | Application | Applies to all sea going ships , except naval ships. | |

| 3 | Definition of terms used in the | Appropriate meaning of technical words used with reference to these regulations meanings of some important terms (*1) | |

| 4 | Deck line | Freeboard deck ref line, 300mm long and 25mm thick painted on the midship side edge. | |

| 5 | Load line mark | Also known as the plimsoll mark, a circle 25 mm thick intersected by a diametrical line 25 mm thick | |

| 6 | Lines to be used with the load line mark | The various freeboard lines used with loadline mark each 25mm thick. | |

| 7 | Mark of assigning authority | Authority to the classification society which has classed the ship to put its initials on the load line mark. | |

| 8 | Details of marking | Explains the colour contrast and method of marking | |

| 9 | Verification of marks | Function of the class to verify the relevant freeboards and confirm it is in accordance to the certificate. | |

| 10 | Information to be supplied to the master | The need to provide a ship specific approved stability booklet with relevant damage stability calculations for masters use. | |

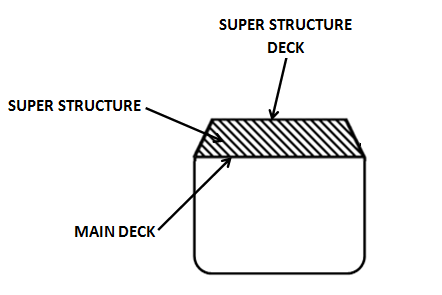

| 11 | Superstructure end bulkheads | Shall be of efficient construction and if needed fitted with approved steel weather tight doors. | |

| 12 | Doors | Specification of approved type steel weather tight doors fitted on all access openings on exposed decks | |

| 13 | Position of hatchways, doorways and ventilators | Weather-tight integrity. | |

| 14 | Cargo and other hatchways | Weather-tight integrity. | |

| 15 | Hatchways closed by portable covers and secured weather-tight by tarpaulins and battening devices. | Specification of older type wooden hatch covers with steel hatch beams. | |

| 16 | Hatchways closed by weather tight covers of steel or other equivalent material fitted with gaskets and clamping devices | Specification of steel hatch covers with securing devices. | |

| 17 | Machinery space openings | Weather tight access to machinery spaces .Weather tightness of skylights and fiddley deck. | |

| 18 | Miscellaneous openings in freeboard and superstructure decks | Weather-tight integrity . | |

| 19 | Ventilators | Weather-tight specifications for cargo hold ventilators. | |

| 20 | Air pipes | Specifications for construction and efficient means of prevention of ingress of seawater into tanks to which these air pipes are connected. | |

| 21 | Cargo ports and other similar openings | specifications for water tight fittings and securing devices particularly when the openings are below the freeboard deck. | |

| 22 | Scuppers, inlets and discharges | Efficient leak proof connections to ship side using doubler flange fitting. water tight integrity | |

| 23 | Side scuttles(port holes) | Specifications of approved type portholes with deadlight blanks. Weather-tight integrity for side scuttles fitted above freeboard deck and water tight integrity for side scuttles fitted below freeboard deck. | |

| 24 | Freeing ports | Prevention of accumulation of sea water on freeboard deck, especially in ships fitted with bulwarks. | |

| 25 | Protection of the crew | Safe weather proof quarters for the accommodation of crew and provision for their safe movement within the ship and for entering as well as leaving the ship. | |

| 26 | Special conditions of assignment for type ‘A’ Ships | Weather-tight fittings for access to pump room, provision of catwalk connecting accommodation house to forecastle and freeing ports if bulwarks are fitted | |

| 27 | Types of ships | Lists tankers(A-type) and dry cargo ships fitted with approved type steel hatch covers(B-type) and(*2) conditional specifications for B-60 and B-100 (B-type) ships. Table for increase of freeboard for ships fitted with wooden hatch covers. | |

| 28 | Freeboard tables | Table A for tankers , Table B for Dry cargo ships fitted with steel hatch covers. | |

| 29 | Correction to the freeboard for ships under 100m in length. | Increase in freeboard by defined formula. | |

| 30 | Correction for block coefficient | Standard C = 0.68 .Freeboard correction factor=(C +0.68)/1.36 | |

| 31 | Correction for depth | Standard L/D =15, where D is greater than L/15 the freeboard is increased by( D-L/15)*L/0.48 mm, at lengths less than 120 metres and 250 mm at 120 metres length and above. Where D is less than L/15 no reduction in freeboard. | |

| 32 | Correction for position of deck line | Applies to ships with rounded gunwale. The position of deck line is shifted below at the junction of sheer strake. No change in freeboard. | |

| 33 | Standard height of superstructure | Standard height varies from 1.8 to 2.3 m as per length of superstructure. | |

| 34 | Length of superstructure | Length of superstructure with attachments within the length of the ship | |

| 35 | Effective length of superstructure | Net length of superstructure. | |

| 36 | Trunks | Trunks are similar to deck houses which do not extend to the sides of the ship. Examples are deck houses on bulkcarriers on which the cargo cranes are mounted. They are fitted with weather tight closing doors and fittings. | |

| 37 | Deduction for superstructure and trunks | Proportional reduction in freeboard as per length of superstructure and trunks. | |

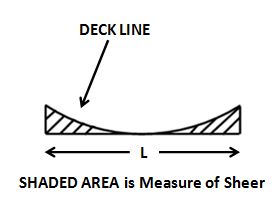

| 38 | Sheer | Sheer is the upward curvature of the Freeboard deck line. The measure of sheer will be explained later as a separate explanation (*2) | |

| 39 | Minimum bow height | Separate explanation (*4) | |

| 40 | Minimum Freeboards. | Summer Freeboard:- obtained after all above corrections applied to tabular Freeboard. Tropical Freeboard:- Summer Freeboard – d/48 m Winter Freeboard:-Summer Freeboard + d/48 m Summer Fresh :- Summer Freeboard + Δ/40T Tropical Fresh:-Tropical Fresh +Δ/40 Winter N A:- For ships less than 100 m long :- Winter Freeboard +50mm. Where Δ is the displacement at summer draft, T IS T.P.C. at summer draft, and d is summer draft. | |

| 41 | Application of this chapter | Regulations 42 to 45 are in this chapter. | |

| 42 | Definitions | 1Timber deck cargo :- The term ‘ ‘timber deck cargo’ means a cargo of timber carried on an uncovered part of the freeboard deck or the superstructure deck. The term does not include wood pulp or similar cargo ( ply wood ) (2)Timber load line:- A timber deck cargo may be regarded as giving a ship a certain additional buoyancy and a greater degree of protection against the sea.. For that reason ships carrying a timber deck cargo may be granted a reduction of freeboard calculated according to the provisions of regulation43,44 and 45 and marked on the ship side as separate Timber freeboards. | |

| 43 | Construction of ship | Superstructure:- Ships shall have a forecastle of at least standard height and a length of .07 L. and a raised quarter deck with either a deck house or a strong steel hood of at least same bow height D.B . tanks :-DB tanks where fitted within the mid-ship half length of the ship shall have adequate water-tight longitudinal subdivision. Bulwarks:- The ship will be fitted either permanent bulwarks at least 1 metre in height, specially stiffened on the upper edge and supported by strong bulwark stays attached to the deck and provided with necessary freeing ports. ,or with efficient rails of the same height and of specially strong construction. | |

| 44 | Stowage | Detailed specifications given for proper stowage, timber uprights and lashings. Stability:-Stability working should include water retention constant on deck for calculating transverse GM and Trim and the range of stability should be drawn for Arrival and Departure conditions Protection of crew :- A portable catwalk at least 30 cms wide to be constructed on top of the stowed timber for the crew to proceed to the forecastle as well as to check the lashings on a daily basis during the loaded passage. Two rope ladders one forward and one aft to be fitted to access the catwalk. | |

| 45 | Computation of Freeboard | The minimum summer freeboard is worked out by applying regs27,28,29,30,31,32,37 and 38. The principle used is that the entire length of the stowed timber deck cargo is considered as a virtual superstructure and the allowable reduction in freeboard as per reg37 specially modified and given in this regulation as based on length of superstructure. Referring to position of summer freeboard the other freeboards are placed as follows:- Winter Freeboard :- Summer freeboard + d/36 m Tropical Timber Freeboard:- Summer Freeboard –d/48 m Fresh water timber freeboard shall be in accordance to reg 40 WNA timber freeboard shall be in accordance to reg 40 |

Explanations

Definitions.

- Water- tight :- Means prevention of leakage of water from a closed opening when the closure is subjected to a predetermined head of water. Example—water-tight door in engine room which is subjected to a head of sea water up to main deck level.

- Weather-tigh t:- Means prevention of leakage of water from a closed opening when the closure is subjected to a strong spray of water, such as a swell hitting a weather tight door. Water –tight condition is more stronger than Weather tight condition.

B-60 and B-100 SHIPS

B-60 :- Dry cargo ships of over 100 metres in length, when loaded up to summer draught, will remain afloat in a satisfactory condition of equilibrium after flooding of any single damaged compartment at an assumed permeability of 0,95 excluding the machinery space. In such ships the freeboards shall be reduced to not more than 60% of the difference between table A and table B for the same length of ship.

B-100 :- In dry cargo ships of over 225 metres in length, the machinery space will be treated as a floodable compartment with an assumed permeability of 0,85. The ship will remain afloat in a satisfactory condition of equilibrium after flooding of any single damaged compartment with assumed permeability 0,95 and the machinery space with assumed permeability of 0.85.In such ships the freeboards shall be reduced to not more than 100% of the difference between table A and table B for the same length of the ship.Limits of status and stability in damaged condition:- The following limits may be regarded as satisfactory:

- The final water line after flooding is below the lower edge of any opening through which progressive flooding may take place

- The maximum angle of heel due to unsymmetrical flooding is of the order of 15 degrees.

- The metacentric height in the flooded condition is

Calculation of deck sheer

The deck sheer, which is the upward curvature of the deck plating starting from mid-ship to the ends forward and aft is provided to restrict the water entering the deck when the ship pitches in a heavy sea. The standard sheer profile is specified under regulation 38. Standard sheer profile stipulates that the forward sheer is twice the aft sheer and this is provided to prevent shipping water on deck as the ship moves forward in a rough sea.

| Station | Ordinate (in mm) | Factor |

| After perpendicular | 25(L/3 +10) | 1 |

| 1/6 L from AP | 11.1(L/3+10) | 3 |

| 1/3L from AP | 2.5 (L/3 +10) | 3 |

| Amidships | 0 | 1 |

Forward Half

| Station | Ordinate (in mm) | Factor |

| Amidships | 0 | 1 |

| 1/3L from FP | 5.6 (L/3 +10) | 3 |

| 1/6 L from FP | 22.2(L/3 +10) | 3 |

| Forward perpendicular | 50(L/3 +10) | 1 |

The profile area of the two halves in terms of length is given as follows ; Forward half = 44’47 L +1334 mm 2 .

Aft half = 22.23 L + 667 mm 2

Consider a ship of length 200 metres. As per above calculation the standard forward half sheer area will be = 44.47*200 +1334 =9561 mm 2

The Aft half standard sheer area will be = 22.23 *200 + 667 =5113mm 2 .

Reg 38.9 states as follows “Where the sheer profile differs from the standard, the four ordinates of each profile in the forward or after half shall be multiplied by the appropriate factors given in the table of ordinates. The difference between the sums of the respective products and those of the standard divided by 8 measures the deficiency or excess of sheer in the forward or after half. The arithmetical mean of the excess or deficiency in the forward and after halves measures the excess or deficiency of sheer

| Station | Ordinate (in mm) | Factor |

| Amidships | 0 | 1 |

| 1/3 L from FP | 200 | 3 |

| 1/6 L from FP | 400 | 3 |

| Forward perpendicular | 600 | 1 |

| Station | Ordinate (in mm) | Factor |

| Amidships | 0 | 1 |

| 1/3L from AP | 100 | 3 |

| 1/6L from AP | 200 | 3 |

| After perpendicular | 300 | 1 |

Forward sheer area = 2400mm 2 , After sheer area =1200mm 2

Applying reg 38.9 we have:

Deficiency Forward sheer = \frac{9561-2400}{8} = \frac{7161}{8} =895.125 mm

Deficiency after sheer = \frac{5113-1200}{8} = \frac{3913}{8} = 489.125 mm

The average deficiency = \frac{(895.125+489.125)}{2}= 692.125 mm

Therefore 692.125 mm will be added to the tabular freeboard

Reg 38.14 : Addition for deficiency in sheer :- Where the sheer is less than the standard, the correction for deficiency in sheer shall be added to the Freeboard.

Reg 38.12 Where sheer credit is given for a poop or forecastle, the following formula shall be used;

S=y/3* L’/L

Where s=sheer credit to be deducted from the deficiency or added to the excess of sheer

Y=difference between actual and standard height of superstructure at the end of sheer.

L’= mean enclosed length of poop or forecastle up to a maximum length of

Minimum Bow height

The bow height is defined as the vertical distance at the forward perpendicular between the waterline corresponding to the assigned summer freeboard and the designed trim and the top of the exposed deck at side shall not be less than; For ships below 250 metres in length,

\frac{56 \ast L (\frac{1-L}{500})\ast 1.36}{C_b + 0.68} millimetres.

For ships of 250metres and above in length,

\frac{7000\times 1.36}{C_b + 0.68} millimetres.

Where L is the length of the ship in metres and C B is the block coefficient which is to be taken not less than 0.68

2 thoughts on “ Load Line Regulations – A comprehensive guide ”

is the ship be able to sail when fwd and aft draft is more than the required loadline considering that the midship is not yet touching the required loadline? given example: Summer loadline=13.20 , Fwd and aft drafts=13.30 , midship draft=13.15 .. vessel in hogging condition.

Dear Sirs, Wanted to Know if a ship loaded at Summer loadline can transit the Winter zone during the winter period,, say panama to China if a ship is going via the Great circle route. Understand the weather is a factor to be considered during the passage, Also could u pls advise if it has anything to do with cargo insurance,, we are gas tanker.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Follow us on Social Media

Username or email address * Required

Password * Required

Note: Entering wrong username in the login form will ban your IP address immediately. Entering wrong password multiple times will also ban your IP address temporarily.

Lost your password? Remember me

No account yet?

Sailorinsight

Connecting Sailors Around the World

The basic concept of load lines on a ship?

The basic concept of load lines

- Load Line ensure that she cannot be loaded beyond her strength

- Load Line provide adequate reserve buoyancy

- Load Line protects the crew.

Conditions of Assignment

- Hull must be adequate structural strength

- Hull must be water-tight

- Hull must be adequate freeing arrangements

- the ship must have adequate stability

- the ship must have adequate motive power.

Assignment of Load lines

- Conditions of assignment survey

- Deck line fixed

- Freeboard computation

- Assignment of FB/LL

- LL marking on ship sides

- Final survey

- Issued LL Cert.

Ships excepted from Load line Convention’s provisions

- ships of war

- ships of under 24 m length

- ships under 150 GT

- pleasure yachts not engaged in trade

- fishing vessels

Ships exempted from Load line Convention’s provisions

- Ship normally trading domestic voyages

- One-off international voyage

- Ship of novel features.

LOAD LINE LAW

Ship may not proceed or attempt to proceed to sea unless:

(1) Surveyed in accordance with the Regulations

(2) Marked with the appropriate marks

(3) Complies with Conditions of Assignment.

- Information regarding stability, loading and ballasting is provided for the master’s guidance.

- Ship may not be so loaded that the appropriate load line on each side of the ship would be submerged if the ship were in salt water and had no list.

SUBDIVISION LOAD LINES

According to SOLAS II-1/Reg 18/Amd-05

- Used for Passenger Ship.

- Requested by the Owner to Administration to additional LL assigned.

- Assigned and mark in PSSC.

- Not survey with LL survey.

- P1, P2, P3 Notification for passenger service configuration R Highest value

(1)Horizontal line at amidships

(2)300mm(L) X 25mm(B)

(3)Intersect the upper surface of F/B deck.

LOAD LINE SURVEYS

(As per LL Convention Art.14)

Initial survey

- Complete inspection of SEMAS (structure, equipment, arrangements, materials and scantling)

- Ensure fully comply with relevant regulations.

- Complete and through examination as follow:

- Ship’s structure (Internally/Externally)

- All fitting (protection of opening, guard rails, freeing ports and means of access)

- Stability, loading and ballasting information

- Test necessary by surveyor

Renewal survey

Inspection of SEMAS, to ensure with requirement of regulations.

Annual survey (formerly called periodical inspections)

- Ensure that no alteration made to hull (or) structures affecting LL position and all fittings.

- Details items follows

- Opening in ship side (below F/B deck)

- Machinery casing and deck houses

- Freeing ports

- Ventilator and Air pipe

- Position of LL/DL

- Any departures from Conditions of assignment

- Special fitting/marking for timber ship

PSC Inspection

As per LL Con. Art.21

- Validity of Certificate

- Not loaded beyond the limits, by Cert.

- Position of LL, by Cert.

- Any alteration of materials.

- Absence of LL Certificate/ endorsement

- Absence of information regarding for stability, cargo and ballast operation

- Insufficient stability

- Overloading

- Impossible to read LL/ draft marking

- Defect of freeing arrangement/closing devices/crew protections

Cancellation of certificate

- the ship does not comply with the Conditions of Assignment;

- the structural strength of the ship is lowered to such an extent that she is unsafe;

- the information on which the freeboards were assigned was incorrect;

- the ship has not been periodically inspected;

- the new certificate is issued; and

- the ship ceased to be registered.

Information on LL Certificates

- Ship name, ON / POR

- Type of ship

- Position of LL/DL/FB

- Diagram of LL

- Date of initial survey/ annual survey

- Date of place of issue

- Certifying authority

- Signature of person issuing.

Definitions

Winter North Atlantic load line

- ships of 100 m or less in length

- either in the North Atlantic Winter Seasonal Zones (I or II) during winter seasonal periods.

Type ‘A’ ship

- Designed to carry only liquid cargoes in bulk;

- such a ship will have:

- high integrity of the exposed deck and

- high degree of safety against flooding.

Type ‘B’ ship

- any ship which is not a type ‘A’ ship.

Freeboard deck

- is the uppermost complete deck having permanent means of closing all openings in weather section.

Weather deck

- is the uppermost complete deck exposed to weather in any sea condition above and at least two sides;

- means capable of preventing the passage of water in any direction.

Weathertight

- means that in any sea condition, water will not penetrate into the ship.

Enclosed superstructure

- if the first tier of superstructure is watertight, it is called an enclosed superstructure.

Statutory freeboard

- the distance from the upper edge of deck line to the centre of the load line disc.

Preparation for LL Survey

- Stability booklet

- Structural strength sufficient

- Deck/Hull …… not corroded/not cracked

- Watertight …. Cargo port / Opening (below FB DK)

- Weather tight …. Hatchway/coaming , Machinery space opening, opening @ weather dk.

- Good condition .. Ventilator, Bulkwalk, railing ,Pumping arrangement

- Operational …… Non return valve , Port holes, funnel flaps, skylight doors

International Load Line Certificate (1966) (ILLC 66)

- issued to ships which have been surveyed and marked in accordance with the Load Line Regulations;

- issued by the ship’s authorized classification society;

- for an un classed ship, it will be issued by the Administration;

- period of validity is 5 years subject to passing periodical inspections;

- “ Record of Particulars Relating to the Conditions of Assignment ” is issued with a Load Line Certificate.

WHAT OTHERS ARE READING

What is Rising and dipping of lights

5 Investment which Gives Financial Freedom for Seafarers

Why do we need Classification Societies?

2 thoughts on “ the basic concept of load lines on a ship ”.

“I appreciate your blog post.

Glad that you shared these tips, such information was much needed for students who are interested in joining merchant navy.

Leave a Reply

Your email address will not be published. Required fields are marked *

- International Convention on Load Lines

- Conventions

Adoption: 5 April 1966; Entry into force: 21 July 1968

- Chapter I - General;

- Chapter II - Conditions of assignment of freeboard;

- Chapter III - Freeboards;

- Chapter IV - Special requirements for ships assigned timber freeboards.

| Clasification Society 2024 - Version 9.40 |

| . are fitted in the buoyant part of the hull within Level 1, the vessel shall meet the enhanced survivability standard as defined in 3.17 (4) of the Code, with the watertight compartment behind the glazed opening assumed flooded and in all such cases the arrangements should comply with all other applicable provisions of this section . they may be tested , to the satisfaction of the Administration, in accordance with the following provisions: |

(3) In individual cases, when the Administration considers that the requirements of the ILLC with respect to freeing port areas cannot be met, the Administration may consider and approve alternative arrangements to achieve adequate safety standards which may take account of a reduced permeability and volume of a well.

AW = Actual area of the well;

LW = Overall length of the well;

BW = Maximum breadth of the well; and

Dimensions are measured at half the height of the bulwark above the deck of the well,

provided that

(a) the maximum reduction shall not exceed 50%;

(b) the stability requirements for the yacht are maintained with all the wells flooded to any level up to the height of the bulwark; and

(c) the freeing port area provided is sufficient to allow the well to drain in less than three minutes.

(5) Any recess in the weather deck shall be of weathertight construction and shall be self draining under all normal conditions of heel and trim of the vessel; a swimming pool or spa bath, open to the elements, shall be treated as a recess.

(6) The means of drainage provided shall be capable of efficient operation when the vessel is heeled to an angle of 10 o .

(7) The drainage arrangements shall have the capability of draining the recess (when fully charged with water) within 3 minutes when the vessel is upright and at the load line draft and means shall be provided to prevent the backflow of sea water into the recess.

(8) Where it is not practical to provide drainage which meets the requirements of Sections (6) and (7), alternative safety measures may be proposed for approval by the Administration, provided that where the above requirements for quick drainage cannot be met, the effect on intact and damage stability shall be considered taking into account the mass of water and its free surface effect.

3.16 Protection of the Crew and Passengers

(1) The deckhouses used for the accommodation of the crew and passengers shall be constructed to an acceptable level of strength

(2) Guard rails or bulwarks shall be fitted around all exposed decks and the height of the bulwarks or guard rails shall be at least 1 metre from the deck, provided that where this height would interfere with the normal operation of the ship, a lesser height may be approved provided that the Administration is satisfied that adequate protection is provided;

(3) Guard rails fitted on superstructure and freeboard decks shall have at least three courses such that the opening below the lowest course of the guard rails shall not exceed 230 millimetres and the other courses shall be not more than 380 millimetres apart;

(4) In the case of ships with rounded gunwales the guard rail supports shall be placed on the flat of the deck.

(5) In other locations, guardrails with at least two courses shall be fitted.

(6) Guard rails shall comply with the vessel’s Recognised Organisation construction requirements or the following provisions-

(a) fixed, removable or hinged stanchions shall be fitted about 1.5 metres apart and removable or hinged stanchions shall be capable of being locked in the upright position;

(b) at least every third stanchion shall be supported by a bracket or stay;

(c) where necessary for the normal operation of the ship, steel wire ropes may be accepted in lieu of guard rails and such wires shall be made taut by means of turnbuckles; and

(d) where necessary for the normal operation of the ship, chains fitted between two fixed stanchions and/or bulwarks are acceptable in lieu of guard rails.

(e) a combination of bulwarks and guardrails shall be permitted providing that bulwarks comply with applicable freeing port area requirements.

(7) Satisfactory means for safe passage (in the form of guard rails, lifelines, gangways or underdeck passages, etc.) shall be provided for the protection of the crew in getting to and from their quarters, the machinery space and any other spaces used in the essential operation of the ship.