The Worldwide Leader in Sailmaking

- Sail Care & Repair

- Sailing Gear

- Find A Loft

- Sail Finder

- Custom Sails

- One Design Sails

- Flying Sails

- New Sail Quote

- 3Di Technology

- Helix Technology

- Sail Design

- NPL RENEW Sustainable Sailcloth

- Sailcloth & Material Guide

- Polo Shirts

- Sweaters & Cardigans

- Sweatshirts & Hoodies

- Accessories

- Summer Sale

- Shop the look

- Mid & Baselayers

- Deckwear & Footwear

- Luggage & Accessories

- Spring Summer '24

- North Sails x 37th America's Cup

- Sailor Jackets

- SALT X North Sails

- NS x Slowear

- T-shirts & Tops

- Sailor Jacket

- Sustainability

- North Sails Blog

- Sail Like A Girl

- 37th America's Cup

- Icon Sailor Jacket

- Our Locations

- Certified B Corporation

- North SUP Boards

- North Foils

- North Kiteboarding

- North Windsurfing

SAIL FINDER

SAILING GEAR

COLLECTIONS & COLLAB

WE ARE NORTH SAILS

ACTION SPORTS

Popular Search Terms

Organic cotton

Scuba fleece

Drawstring hood

Utility pocket

Stand collar

Sorry, no results for ""

Subscription

Welcome aboard.

We want to make our emails as relevant as possible for you.

Interests saved

Something went wrong, please try again

Welcome to North Sails

Stay up to date with the latest North Sails news.

Receive a 10% discount code for your first apparel order. Excludes sails and SUP’s. See our Terms and Conditions .

Yes, I agree to the terms of use and privacy policy.

FIBERS & FABRICS: A SAILOR’S GUIDE

Everything you need to know.

Modern sailcloth begins life as industrial fiber and film. Some of these products are well known to sailors by a specific supplier’s brand name; but in many cases the material properties of these products are not especially well understood. A better understanding of the characteristics of these fibers can be helpful in choosing the right sails for your boat.

The ideal sailcloth fiber would last for decades of use, stand up to the harsh sailing environment (toughness and structural durability), would not stretch under load (modulus and shape holding) and would be low in cost. But in the real world, available fibers exhibit varying degrees of these attributes with some materials having vanishingly small levels of stretch for weight, but less than desirable durability, while others are tough, but somewhat stretchy. Finding the right balance of properties for your type of sailing and keeping within budget is the key to being happy with your sails.

Let’s start with the various fibers found in abundance in top quality sailcloth, and then look at the more anomalous products that have appeared (and in some cases later disappeared from sailmaking applications).

Polyester has for decades been the most commonly used sail fiber because it is strong, durable and relatively inexpensive. Woven polyester sailcloth is often called “ dacron ”, in reference to the brand name given by DuPont to their Type 52 Dacron yarn, which was developed specifically for sailcloth and was the industry standard for years. Over the years other suppliers have introduced premium polyester yarns well suited to sailcloth. Premium polyester yarns deliberately feature very high shrinkage when heated during the finishing process. High shrinkage, combined with very tight weaving, produces sailcloth which is tightly packed and stable without having to rely on on adding excess (and less durable) resins for stability. Polyester fabric is used both as stand-alone woven cloth and as a component in laminates. Polyester yarn is quite resistant to UV damage.

Nylon is widely used for spinnakers and asymmetric spinnakers (Gennakers™) because it is low cost, is lightweight for its strength, and exhibits good UV stability. Nylon is quite stretchy (a big part of why it has very good strength), which is not a liability in downwind sails where some sail stretch is desirable. One warning about nylon to bear in mind: while nylon is a rugged material, it is very susceptible to damage from exposure to chlorine. Never use bleach when washing or rinsing nylon sails, and never soak a nylon sail in a swimming pool.

Aramid fibers are lightweight, have high resistance to stretch and high breaking strength. Not surprisingly aramids are often the fiber of choice for racing sails, and can also be viable in laminated cruising sails, when properly protected from excess UV and flexing. Kevlar® (a Dupont product) and Teijin’s Twaron® and Technora® are commonly used aramid fibers in sails. Aramid fibers are often blended with even lower-stretch and higher strength carbon fibers within the same racing sail. While not inexpensive, aramid fibers are moderately priced in comparison to the most exotic fiber types.

Ultra PE (UHMWPE) was originally introduced as a competitor to Kevlar. The brand names Dyneema®, produced by the Dutch company DSM, and Honeywell’s Spectra® are familiar to many sailors. These fibers are highly processed polyethylenes which offer very good UV resistance, very low stretch and very high breaking strength. Ultra PE fiber does exhibit some tendency to “creep” (elongate over time when kept under sustained high load). As a result the UltraPE mass in sailcloth needs to be relatively high compared to expected sail load. “Spectra/Dyneema” has been used primarily on larger cruising boats where reasonable weight, strength and durability are paramount. Ultra PE fiber is expensive, but very long sail life ensures high value in these sails.

Carbon Fiber appeared in sails during the 1992 America’s Cup and has since been widely accepted in grand prix sailing – including high end cruising applications. Carbon fibers are impervious to UV damage and have extremely high modulus (low stretch), but are quite sensitive to flex. If you take a raw carbon fiber tow (yarn) and fold it in your fingers it will snap after only one or two hard folds. Depending on the carbon content and the construction of the sailcloth, crews need to be very careful to avoid flogging and hard creases when flaking or folding a sail. A notable breakthrough in the utilization of Carbon is in blending it with Ultra PE fiber where the two material’s complementary properties are synergistic.

Other Fibers – Current and Obsolete New fibers occasionally come out of the petrochemical company’s labs, and often prove to be of limited utility (or just plain unsuitable) for sailcloth applications. North’s approach to new fibers is to first carefully examine the laboratory performance figures, determine a likely appropriate use for the fiber, engineer the right fabric design and choose appropriate sail size range. Finally, we require an extensive testing period to make sure any new fiber lives up to its (often unfounded) promises.

PEN , sold under the brand name of Pentex™, is available in a relatively limited range of yarn sizes. PEN fibers are related to polyester (PET) but stretch about half as much (PEN is only 1/5 higher in strength). This relative mismatch between stretch and strength performance means a PEN based sailcloth cannot be truly lightweight in actual use. The cost of PEN falls between polyester and the aramids. PEN use is mostly driven by class and rating rule restrictions where aramid fiber is not allowed. PEN fiber has low shrinkage when heated during finishing, so it cannot be woven tightly like polyester. For this reason, PEN fibers are found only in combination with PET (aka “mylar”) film in laminate cloth for paneled sails. PEN does not come in woven form.

LCP (liquid crystal polymer) is a lightweight fiber that performs well for stretch and flex, but is consequentially more sensitive to UV exposure than Aramid. Vectran is the commonly heard brand name for LCP fiber. North Sails does not use LCP in any sail materials as the cost/durability/performance equation is simply not compelling.

PBO is an example of a highly touted ultra-high-performance fiber that failed as a sail material. Made by Toyobo in Japan, it beats all but the most exotic carbon fibers in stretch and strength for its weight. But PBO is very susceptible to sunlight and flex damage, so PBO based sails proved very short lived.

GET IN TOUCH

REQUEST A QUOTE

BROWSE ALL SAILS

FIND YOUR SAIL

Featured stories, offshore sailing guide, how to care for your foul weather gear, npl renew faq.

- Refresh page

Home > Education & Expertise > Sailcloth

Precision Sails is proud to offer the largest selection of sailcloth in the industry. Whether you’re a weekend warrior on a 16′ boat, a world explorer sailing your home around the world, or a speed demon with a desire to finish first in your club and long distance races, we can find the cloth for you. The correct sailcloth for your boat depends on the area that you sail in and the type of sailing you like to do. This can often make choosing a cloth difficult and overwhelming. Don’t worry, we can help. Precision Sails’ dedicated sail consultants will walk you through the process.

What sailcloth do we use?

First run sailcloth.

Precision Sails only uses first run sailcloth for all of our sails. All sailcloth is manufactured to industry standards for quality. However, when mistakes happen, or flaws are discovered in rolls, cloth manufactures will offer these “seconds” at a discounted price because of the small imperfections in the cloth. Although this cloth may be fine for some applications, we choose to only use first run sailcloth because we believe that if we are going to spend the time designing a perfect sail, we should build it with a perfect cloth.

Welcome to the world of choice

In the sailmaking industry there are sailcloth manufacturers and sailmakers. Precision Sails designs and builds sails using the top manufacturers of Dacron sailcloth, Nylon Spinnaker cloth, and rolled Laminate sailcloth. Even though all sailmakers have access to the same suppliers of sailcloth, many choose to only work with a limited number in order to reduce their inventory requirements. At Precision Sails we’re different. Here, you have the world of choice, and that means we can guarantee that you’ll find a cloth choice to suit your needs. Learn more about the brands we work with below.

Trusted Brands With Unparalleled Experience

At Precision Sails, we work with industry-leading brands, like Bainbridge and Contender to offer a wide variety of sailcloth options to ensure that your perfect sail is made from the right cloth. Our team understands the ins and outs and the pros and cons of each cloth we use in our loft and can help you make a decision based on your sailing requirements.

Contender Sailcloth

Contender supplies sailmakers all over the world with a full range of cloths for modern sail design. They offer woven Dacron for cruising and racing, Spinnaker Nylon in multiple colors and weights, and Laminate sailcloth for performance cruising and racing.

Bainbridge International

Bainbridge International is one of the longest established sailcloth manufacturers in the world. This company has almost a centuries experience in developing and supplying the highest quality and performance materials to the marine industry. Bainbridge has always been at the forefront of technical developments within the world of sailcloth. Through the skills of their technical team, Bainbridge has developed a number of products including AIRX Performance Spinnaker Fabrics, MP Multi- Purpose Spinnaker Fabrics, DIAX Laminated Sailcloth, and SAILMAN Full Batten Systems. These have been used by many high profile campaigns including America’s Cup, Vendee Globe, Volvo 60, and BT Global Challenge.

Dimension Polyant

Dimension Polyant’s core pillar is quality. They combine traditional craftsmanship with state of the art production facilities at the highest technological level. As the world market leader in the field of sailcloth, every piece that leaves their factories in Kempen (Germany) and Putnam (USA) benefits from their experienced, innovative development teams, and industrial manufacturing knowledge. Dimension Polyant develops, weaves, laminates, and finishes to the highest quality standards.

Challenge Sailcloth

There are many different factors that are considered in the construction of sailcloth. Challenge Sailcloth is confronted with a common question from many sailors, “Which fabric is the best?”. Challenge Sailcloth, or any cloth manufacturer, does not make one fabric that is better than another. They make many different fabrics for many different applications. Challenge has been able to match the advancing technology in the industry to produce a wide range of products lines for their customers in both racing and cruising markets.

Mazu Sailcloth

The foundation of Mazu Sailcloth lies in its experience and passion for the sea and is based on more than 30 years in the yachting, sailmaking, and sailcloth industries. Mazu is wholly dedicated to offering sailmakers the best sailcloth styles, the best construction, and the best consistency.

Cruising Dacron Sails

Precision Sails offers the largest selection of Crosscut and Radial Dacron sails in the industry. Whether you are sailing with the family at the summer cottage a few weekends a year or cruising around the world, there is a Dacron made precisely for your needs and within your budget.

Each sailcloth manufacturer offers several qualities of Dacron to choose from in order to fit your needs. We’ve grouped sailcloth of similar qualities from each manufacturer to help you make a well-informed decision about what’s best for you!

Cruising Laminate Sails

Laminate cruising sails are best suited for sailors who are looking for improved performance through better sail shape, and retention of sail shape over the life of the sail. These types of sails are produced using the same methods as racing sails. However, they are built with longevity in mind using Polyesters and Taffeta to increase durability and ease of care.

Laminate sailcloth is designed to resist stretch under initial load, as well as stretch over time.

Long Distance Cruising & Circumnavigation Sails

Long distance cruising and circumnavigation offers sailors the freedom to move their floating home to unlimited locations throughout the world. This type of sailing has unique sailcloth needs. Even though ocean crossings have become more predictable with modern forecasting and prediction software, you still need sails that are prepared for changes and inaccurate wind and wave forecasts.

Club Racing & Long Distance Racing Sails

Racing sails are built for speed. Precision Sails has access to the best Racing Laminate sail cloth offered in the industry. Whether you are racing against your fellow club members in “beer can” races just for fun or campaigning your boat in long distance races for bragging rights and prize money, there’s a Racing Laminate sail that will meet your expectations and your budget.

Cruising Nylon

With a long life span and durability in mind, Cruising Nylon is designed for performance cruising with yachts and long-distance. Our Cruising Nylon’s abilities are well suited for radial sails. They have excellent tenacity and strength making it an ideal choice for those long trips or circumnavigations. With built-in UV protection and low-shrink Polyester yarns, these cloths will give you an excellent finish that you can rely upon for years to come.

Racing and Club Racing Nylon

With Bainbridge and Contender’s range of performance fabrics, these sailcloths promote high performance, low weight, no porosity, and water resistance. Combined, this equates to excellent shape retention and flying temperament. Our series of Racing Nylons is ideal for the avid sailor who insists on a stellar performance.

Sailing Resources

Learn more about Precision Sail Loft, including our resources on sail maintenance, and trimming techniques. You can also find our digital showroom featuring hundreds of videos of various sails made from many different cloths.

Installing A Lazy Jack Bag: Calico Skies

Ask Precision Sails , Featuring – Partners , Installation

Calico Skies recently installed their new Precision Sails Lazy Jack Bag. Learn about what the system is and how you can install one on your sailboat.

What To Do If Your Spinnaker Wraps Around The Forestay

Ask Precision Sails , Featuring – Partners , Spinnakers

A spinnaker wrapping around your forestay can be a scary experience. It’s important to know what causes it to happen and how to safely recover from a spinnaker wrap.

Building Sails For The Royal Canadian Navy

Ask Precision Sails

Darryl, CEO of Precision Sails and creator of I Dream Of Dinghy, documented the process of measuring, designing, and installing new sails on two Bavaria C45 sailboats that the Canadian Navy purchased for their training program.

" * " indicates required fields

Thanks for telling us a bit about yourself and your boat. Our team will send you a preliminary quote based on information we have gathered from sailors similar to you.

We will give you a call in order to narrow down the options on your quote and improve the accuracy. If you want us to call you at a specific time, feel free to schedule a time on our calendar!

Thanks for telling us a bit about yourself and your boat. Our team will reach out to offer some suggestions and get started on finding you the perfect sail!

My Cruiser Life Magazine

Sailing Materials – What Are Sailboat Sails Made of?

Of all of the sailing materials found on the modern cruising or liveaboard sailboat, the sailing fabrics that make up the sails and lines may be some of the most space age. Sailing materials have advanced remarkably in the past 100 years, and the progress seems to keep speeding up.

There are still plenty of boats flying their trusty old Dacron sails, that’s for sure. But there are also more and more boats using advanced laminate sail fabrics. So let’s look at the differences and figure out which is right for your boat.

Table of Contents

Traditional canvas and “tanbark”, dacron sails, nylon sails, laminated sails and carbon fiber sailcloth, standard sail patterns, load-path sails, weave patterns in sailboat sail materials, the most crucial part of a sail design.

- Modern Sailboat Construction and Materials

Sail Materials FAQs

What are Sails Made Out Of?

Sail making material has actually changed dramatically in the last century. For example, the sails of the tall ships of yesteryear were made entirely of natural fibers, yet such a delicate thing is nearly impossible to find on a sailboat today.

But sails have progressed. What are sails made of? The most common material used today in Dacron, a synthetic fiber made of polyester. But progress doesn’t stop there. Today, sails are designed from the ground up in the loft, built fiber by fiber, for that specific application. Today’s racing sails and high-tech and truly marvels of modern engineering.

There are only four basic choices of fabric for sails.

- Natural fibers like cotton canvas, which are very rare now

- Synthetic modern fabric like polyester fiber Dacron, the most common sail material

- Lightweight fabrics like nylon, which is used for spinnakers and downwind sails

- High-tech composite fabrics called laminates, which are used on racing sailboats

Before the middle of the 20th century, sails were made of natural fibers (just like everything else on a boat). Cotton canvas was the material of choice but rotting was a major problem. Imagine what would happen to a cotton t-shirt left out in the sun and salt air 24/7/365.

To help them last longer, cotton sails are tanned using tannins from tree bark. Tanbark sails, as these are called, have a reddish-brown color and are more resistant to rot, mold, and mildew.

The modern fabrics that replaced cotton have fixed most of the problems with rot, so real tanbark sails are basically a thing of the past. However, some modern sailcloth options are sold in a tanbark color for sailors who want that traditional look. True cotton sails are not an option for modern sailors. Even if you wanted to deal with the problems and expenses involved, finding a supplier for them would be next to impossible.

If anyone is still flying cotton sails out there, the only purpose would be for historical authenticity. Several museum ships around the world are maintained using original supplies and original materials. They have to source and sew their sails all from scratch.

Plastics changed nearly everything. Today, it’s nearly impossible to find a product that doesn’t contain some amount of plastic. Most types of sailboats are nearly all plastic when you look closely.

The canvas that most sailors associate with sailing is a woven acrylic cloth commonly referred to by its trade name, Sunbrella . It’s waterproof and extremely resistant to UV damage. It comes in a rainbow assortment of colors, although most boaters seem to prefer blue or green. Grey, tan, and red are also common, but you can find hundreds of options if you’re feeling creative. Sunbrella is used all over the boat–but not for sails.

The cloth used for sails is very similar, but it is woven heavier and more resistant to stretch. It is also most often referred to by its trade name–Dacron. Dacron is white in color 99-percent of the time. But it is also sold in tanbark, a reddish color that looks traditional.

Colored Dacron sailcloth is becoming more common, although it is still rare to see it on the water.

Dacron is the type of sail material you’ll see on nearly every sailboat you find. Dacron comes in various thicknesses or weights. The heavier the fabric, the stronger it is to take on heavy weather sailing. So a storm sail will be built out of heavy-weight fabric, whereas a 155-percent genoa made for light air will be made out of lightweight material.

The design and weight of the sail are matched for its purpose. Most boats are equipped with a set of sails that can do all conditions–but this nets you a “can do everything moderately well” sail. If you want light-air sails, the lighter fabric is then too thin to fly when the wind pipes up. If you want heavy-weather capability, the fabric will be too heavy to fill when the wind is light.

Dacron is still the number one choice for most sailors because it’s widely available, easily repaired, reliable, and affordable.

More often than not, if you see a colorful sail, it is made of nylon. Nylon is another type of synthetic fiber, but it is woven thin into very soft and billowy fabrics. Many of us own nylon windbreakers or know of the ripstop nylon used in tents, umbreallas, or even parachutes.

When used for sailmaking, nylon is good for light wind sails. It’s not strong compared to Dacron but it is lightweight. That makes it good for catching the slightest puff of breeze. Spinnakers are made of nylon, and since they look and feel like parachutes, sailors often call them “chutes.”

Unlike Dacron, nylon is widely available in any color you could want. Spinnakers are usually creative expressions of the crew or made to match the boat. They often have many colors stitched together in colorful patterns, just like hot air balloons.

The hottest thing in sailing is laminated sailcloth. The word “laminate” refers to a combination of materials stacked together to make a composite structure. For example, our hulls are made of fiberglass laminates. Racing boats have sails that are often laminates made of high-tech fibers and fabrics that offer maximum performance, strength, and sail shape.

Laminate sails start with a Mylar sheet base layer. High-tech fibers are then laid out and glued to this base. Finally, a material called taffeta gives the sail some strength and resistance to chafing. With so many options of materials, all layered one on top of the other, the sail can be precisely the shape the designer intends. Laminated sails are usually black or grey in color, and are sometimes transparent.

Eight different sailing fabrics can be used in laminate sails.

- Carbon fiber sails

- Spectra or Dyneema (Aramid fibers)

Laminated cruising sails offer the best performance and sail shape, but they are extremely expensive and generally not for your average cruising boat. They tend to offer shorter service lives and are more prone to UV damage than Dacron sails.

These high-tech sails can be made in one of two ways. First, the laminate materials may be created in rolls, just like Darcon or any other woven fabric. The sail loft then takes the material and cuts the panels to make a sail. The sail can be cut crosscut, tri-radial, or bi-radial, just like any other.

Alternatively, some lofts are now creating the laminate fabric as they manufacture the sail. This allows them to orient the strongest fibers of the layup in the perfect place to take the load placed on it during sailing. These sails are called load-path sails. North Sails 3Di sails are an example of this super-cool technology.

Sail Material Design, Cut, and Weave

The sail manufacturing process is an involved one. Sails are sized for the boat and customized for the cruising conditions in sailing and the style of the sailor at the helm . As a result, there are seemingly endless choices if you want to replace your sails, from the materials used, the sail design and cut to use, the conditions you’ll be expecting, and your goals for your boat performance-wise.

Sails are unique in that they must have a specific shape to power the boat. A perfectly flat sail is ineffective. Instead, it should have a curve like an airplane’s wing. This curve, called the draft, must be built-in. Sailmakers cut each piece of the sail with this in mind, and then the completed sail can have as much or as little curve as necessary.

There are three main types of cut that a sail can have to accomplish this–crosscut, tri-radial, and bi-radial. Each type varies in complexity and cost to manufacture and provides a different amount of shape-holding potential throughout its service life.

Crosscut Sails

Most sails you find will have crosscut designs. These sails are cut in strips that run from forward to back at a slight angle. Once the entire sail has been stitched together, reinforcements are added at each corner.

Stretching is a natural part of a sail’s life as it is trimmed and filled with wind. A crosscut sail does not have any extra structure to help it resist stretching, so they are more prone to it than other cuts.

When a sail has been stretched so far that it loses sailing efficiency, it’s said to be “blown out.” When crosscut sails blow out it will be a gradual process as the panels stretch a little bit at a time.

Tri Radial Sails

Tri-radial cut sails have a distinctive look to them. The panels that make the sail are smaller triangles that radiate from each sail corner. Tri-radial sails are made of more panels than crosscut ones, so there is more potential for a knowledgable sailmaker to fine-tune the design. This can result in a more efficient sail shape.

The extra seams in the sail also reinforce the sail overall. This results in a sail that doesn’t stretch as much over time. But once it does go, it is likely to blow out and needs replacement quickly.

If you’d like to see a detailed look at how the pieces of a tri-radial sail fit together, check out this DIY video from Sailrite. Sailrite sells sew-your-own sail kits, with the parts cut from CAD-designed plans.

Biradial Sails

A bi-radial sail is just like a tri-radial, except that the panels that make the design come from only two corners–the head and the clew.

Load path sails are built piece by piece in the loft using composite laminates. Instead of starting with sheets of material, the loft starts with the raw materials that will make the completed sail. Then, it is glued together into the final shape, with strong fibers reinforcing its built-in shape.

Not all fabrics are woven together in the same way. Dacron can be woven in multiple ways, and your sailmaker must know how to combine the right weaves with how the fabric is cut for the sail. The weave is designed to provide strength in one direction and shape in another.

Quite often, the difference in price between two similar-looking pieces of Dacron comes down to the weave. This is because the weave gives the Dacron “tenacity.” High-tenacity Dacron fabrics are best for cruising sails because they stretch less and distribute the load evenly over the sail.

It’s also important to consider the weave of the material when choosing the cut of the sail. For example, a cloth that works for crosscut sails will not be best for a radial cut sail. In addition, some manufacturers weave the Dacron with high-tech fibers, like Dyneema, for extra strength.

The important thing to know is that the weave of the sail cloth fabric you chose must match the cut of the sail’s panels. In other words, you can’t use the fabric from a tri-radial sail to make a crosscut sail or vice versa.

Picking the Right Sailboat Sail Material

For the amateur sailor, sorting through the dizzying array of choices of sailboat sails material is daunting. The flashy racing sails and load path sails are tempting, but are they worth it?

The truth is, Dacron is still popular for a reason. If you’re lucky enough to be outfitting a $500,000 aluminum sailboat , buying the best of the best only makes sense. But most of us are on a budget when outfitting our boats.

What’s more, will you notice the difference between a high-tenacity high-end Dacron compared to a laminate? The answer is probably no on an older, heavy displacement cruising boat. But, on the other hand, on a high-performance catamaran or trimaran, it might be well worth the investment.

Here’s a video from renowned sail loft Precision Sails discussing the most important factors when choosing your next set of sails.

Modern Sailboat Construction and Materials

Our boats have progressed a lot since the wooden-hulled and canvas-sailed ships of the past. Revolutionary new materials mean boats and sails that resist water, pests, and UV damage. As a result, years are added to the life of parts, and maintenance costs are reduced in the process. And if there’s one thing that every boater can agree on, it’s that most time sailing and less time doing maintenance is good news.

Sails are a major investment. For the average boater, a set of new sails should last ten or more years. Unless you’re planning on circumnavigating or racing competitively, most people never have to replace a set of sails. If you are faced with the choice, be sure to consult with a knowledgable sail loft that is familiar with your boat and your goals for it.

What are the materials used in sailing?

Sailboat sails are usually made of Dacron, a synthetic fabric made of polyester. It is very heavy, resists tearing, is waterproof, and resistant to UV damage.

What is the best material for a sail?

Nearly all sails on cruising boats are made of Dacron, a trade-name for polyester fabric. Dacron is long-living and resistant to water, UV damage, and rot.

What material are sailboat sails made of?

The most common sail material is Dacron, a type of polyester fabric. Alternatively, racing boats or yachts may have laminate sails made of high-tech materials like Kevlar or carbon fibers.

Is boat sail material waterproof?

Yes, the materials used in sailmaking do not absorb water. Dacron is the most common material, and it is extremely water-resistant.

Matt has been boating around Florida for over 25 years in everything from small powerboats to large cruising catamarans. He currently lives aboard a 38-foot Cabo Rico sailboat with his wife Lucy and adventure dog Chelsea. Together, they cruise between winters in The Bahamas and summers in the Chesapeake Bay.

Leave a comment

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

What Are Sails Made Of? (And What's Right For You)

Last Updated by

Daniel Wade

June 15, 2022

Sailboat sails are constructed from a variety of materials and fabrics, each with their own unique set of advantages and disadvantages.

Many are designed to provide resiliency from weather conditions that could include constant sunlight and wind abrasion, while still others offer optimal weight distribution and a greater degree of maneuverability.

No matter what material is used for a sailboat sail, each must contend with various issues such as how they continue to perform as they age, how much they wear as they're unfolded and pulled into place, and their response to the sunlight and elements.

All of these considerations factor into choosing the perfect sail for any given situation, with a multitude of fabrics, materials, and options to select from.

Table of contents

What fibers do sails use?

The fibers from which sailboat sails are made could include any number of natural or synthetic materials, that can range from cotton, flax, or hemp, to polyester, nylon, and more. Deciding upon the right one usually depends on what type of sailboat you are using or your reason for sailing.

The most common material used in sails is also the most budget-friendly, known as "Dacron" within sailing communities, it's more often referred to as polyester by the rest of the world.

While this is a very typical choice among recreational and casual sailors, when it comes to more demanding needs, the fabrics and materials can get as exotic as kevlar, mylar, or carbon instead.

Sail Durability

While all sails have their benefits and strong points, some are more durable and sturdy than others. For example, laminate sails which are constructed from multiple layers of film glued together, are able to withstand extremely high wind speeds and are also very resistant to damage from the sun's UV rays.

Those in search of a long-lasting and durable product may find laminate sails to be their ideal option, despite the higher price point. It also isn't uncommon to find companies that offer products developed from a combination of materials, such as those developed from aramid-kevlar or numerous other custom-made fabrics.

Performance Sails

Performance sailing carries with it a unique set of demands that aren't usually shared among casual or recreational sailors. Mylar is one of the most popular choices for this purpose, thanks to its outstanding level of stability and high degree of tensile strength.

This makes it a sought-after choice for those involved in racing or simply anyone looking for a tight and accurate response. The material used in a sailboat sail is commonly referred to as "sailcloth" and can be woven, spun, or even molded into place (as with laminates).

Sail Measurable Factors

Fibers are the heart and soul of each type of sailing fabric, with a wide variety of performance factors that come into play. Cost-effectiveness is one very common consideration, measuring both the initial price of the sail, as well as how expensive it can be over the course of time.

Another measurable factor of the performance of sail fabric is known as "creep", which has to do with how much a sail tends to lose its shape over consistent and continued use. Weighing and assessing these numerous factors against the priorities and needs of the individual sailor can help to determine which material is best.

Flex Strength

Flex strength is a term used to indicate the capability of a given sail (and the material from which it's made) to maintain its strength after having been folded back and forth throughout the course of normal use.

It isn't uncommon for performance sailboats and racing boats to feature sails that need changing more frequently than those on other sailboats, and for this reason generally have a lower flex strength.

Not only is polyester fiber one of the most resilient and affordable choices, but it also has the added benefit of featuring excellent flex strength. This makes it an optimal material for casual sailing (often called "cruising", or "cruise sailing") on a regular and ongoing basis.

UV Resistance

One of the most UV resistant forms of sailboat sails available on the market comes from those manufactured using carbon fiber, which is virtually unaffected whatsoever by the sun's powerful and potentially damaging rays.

Carbon Fiber Sails

There is a wide spectrum of carbon fiber materials that exist for sailboat sails that can vary from nearly no stretch whatsoever, to highly flexible and durable sails which are comparable to other commonly used materials such as aramid.

While carbon fiber clearly ranks at the very top of available materials in terms of performance, its main detriment is the high degree of degradation it suffers due to flexing when compared with materials such as polyester. Thanks to its industry-leading performance and UV protection, carbon fiber also finds itself as one of the most expensive options on the market for sailing materials.

Polyester Sails

Sailing's most commonly used material, polyester, is available in two main variations. PET, short for polyethylene terephthalate, is the number-one most common fiber used in the world of sailing today.

Long having been replaced by stronger fibers when it comes to racing and performance, it remains a highly coveted option due to its resistance to abrasion and very low cost.

Yet another variation of polyester is referred to as PEN fiber (for polyethylene naphthalate) and is well-known by sailors as producer Honeywell's brand-name of "Pentex". PEN fibers are not considered to be lightweight, and stretch only about half as much as PET fibers while being just 1/5 better in overall strength.

Aramid Sails

On the other end of the spectrum is a fiber known as aramid, which is very lightweight yet also extremely resistant to stretching.

It features a very high breaking strength, and for this reason is a highly popular choice for racing sails.

It's commonplace to find aramid fibers blended with the even less stretchy and higher strength carbon, or used in laminate cruising sails.

Though considered to be somewhat of an exotic material, aramid is still moderately priced and can often be purchased for much less than carbon or other fibers.

Nylon Sails

Spinnakers are a unique type of sailboat with their own set of ideals when it comes to finding the right sail fabric. One of the most common choices is nylon, which is usually quite cheap, fairly lightweight, and boasts a surprising amount of strength.

Nylon can be very durable, while also offering a formidable amount of protection against UV rays.

Spectra Sails

Another very common option when it comes to spinnaker sailing is spectra, which provides superior UV protection and breaking strength along with high flex strength and very low stretch. As the sail ages however, it can give way to a change in shape as a result of permanent elongation with sustained use.

Signs Of Wear

As sails are used, they eventually tend to show signs of wear that include stretching in high load sections. This can cause steering to become more difficult while also impacting the shape and effectiveness of the sail.

By selecting sail materials that are more resilient to winds and have greater strength levels, these negative influences can be kept to a minimum.

Today's modern sails are expertly crafted to the highest standards of detail and precision, thus being capable to contend with harsh conditions far better than sails used long ago.

The History Of Sails

Animal skin sails.

It is highly likely that the earliest sailboat sails were fashioned from animal skins, used on raft-like craft and dating back as far as 3300 BCE.

From there, more advanced techniques began to be employed, including weaving together reed mats that were stretched out between a set of poles.

By the time France, England, and Spain began duking it on on the high-seas over naval supremacy, sailcloth had started being fashioned from weaving together flax fiber for a reliable and consistent hold.

Eventually, this method would later be replaced with cotton sails for its improved quality and canvas.

Cotton Sails

The use of cotton as sail material had its advantages over flax and hemp, but not without its own set of unique drawbacks. Although cotton would be able to maintain its shape better and keep less wind from getting through, it also tended to be extremely rigid and stiff which made it challenging to steer in harsh or windy conditions.

Popularity of cotton sails soon caught fire worldwide in 1851, shortly after a United States racing yacht by the name of America soundly defeated a fleet of British yachts in competition (at the time, an unheard of feat). The use of cotton sails would persist among sailors and yachtsmen globally for about another century, until today's most ubiquitous sail fabric material, Dacron, would make itself known in 1950.

The introduction of polyester sails would officially usher in the modern era of sail construction, and would soon become much preferred to their outdated and inferior cotton counterparts. Sold under the"Dacron" moniker in the U.S. and by the name "Terylene" in the U.K., these new sails were able to keep their shape for years at a time - a stark contrast to the previously used cotton equivalent. The heat pressing process of these sails helped to deliver a higher degree of strength, while also providing a much improved lightweight design. Thanks to the way these fabrics are manufactured and treated, the impeccably smooth surface allowed nearly no air whatsoever to escape through pores or holes in the material.

Sail Grouping

Overall, there exist two main categories that sails fall into; those being fore-and-aft sails (which are generally triangular in shape) and square sails. These are further distinguished by being either primary sails which serve as the main propellant of the ship, or secondary sails that serve to assist it.

Sails are also grouped by function, such as summer or tropical weather sailing , cruising, storm sails and more, which can help narrow down the most appropriate construction materials to use. Modern synthetic fibers make up the vast majority of sail fabrics in use today, and there are configurations tailored to every kind of sail and sailboat on the water.

Sail Construction

Sailcloths can be constructed in numerous ways, but are typically either woven or pressed together in a film of some sort (such as a laminate).

Breakthroughs in the world of sailcloth materials are taking place all the time, with experimental and innovative fibers hitting the market to accommodate nearly every type of sailor or sailboat imaginable.

It's hard to argue that we've come a very long way from the early days of the vikings, who set sail across Iceland and Scandinavia in the 19th century using sails made of wool.

Today's composite materials have risen enormously in complexity, with entire lines of trademarked and patented custom fabrics and materials from businesses all around the world.

Choosing The Right Sail

Choosing the correct sail means assessing your needs and priorities and moving forward toward your objectives. Even more variations of sails exist within the categories already mentioned, such as panelled sails which are a unique variety of laminate sail.

There are also fiber path and membrane sails, which each employee specific production in manufacturing techniques to achieve a consistent and reliable bond. Dyneema is one example of a widely known and used proprietary fabric, produced by Dutch firm DSM, and is growing in popularity both as a standalone fabric in its own right as well as a supportive material when combined with carbon. A near endless number of weaves exist, including the "DCX" Dacron, "D4" Load Path, " Square" Sailcloth, and more.

Sail Suppliers

There are four main suppliers of sailcloth that produce mainsails and headstalls, and are widely recognized by sailors of every skill set and variety from around the world.

These include Challenge Sailcloth, Bainbridge International, Contender Sailcloth, and Dimension Polyant.

Having a near Limitless abundance of cloths, materials, and state-of-the-art manufacturing techniques means that today's new and experienced sailors alike will thankfully not be limited when it comes to finding and selecting the perfect fabric and materials to complete their sailboat configuration.

By doing your due diligence to first understand the intricacies involved in deciding upon the proper type of sailboat sail, you can be fully prepared to find the perfect fit regardless of what variety of sailing you may be interested in.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Learn About Sailboats

Sailboat Parts

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Affordable Sailboats You Can Build at Home

September 13, 2023

Best Small Sailboat Ornaments

September 12, 2023

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

- Masting, rigging and sails

- Remember me Not recommended on shared computers

Forgot your password?

Your best sail cloth and technique

By steven sturgis March 11, 2015 in Masting, rigging and sails

- Reply to this topic

- Start new topic

Recommended Posts

Steven sturgis.

Hi every one. I have been looking for the best sail cloth for my Flying Fish build. I would like to get a lot of suggestions that I can look at. Please include where the cloth can be bought. Do you change the color with dyes? do you age the cloth some how? How do you add detail to the sails? All sail makers are welcome to post their designs I know a lot of you don't put on sail because it covers the rigging so anyone that does would be a great asset to the topic. Looking forward to seeing your tricks and designs.

sail techniques http://modelshipworl...-and-technique/

Link to comment

Share on other sites.

Click on the Nautical Research Guild Home Page straight up to the top of the page, then, click on Ship Modeling Resources, then, click on Ship Modeling Database of Articles, Then click Rigging and Sails, then click the pdf "Making and forming sails for your model."

I could have pasted the direct link, but thought it better for you to see everything that was available here on MSW.

You can go to a Joanne's or any yard goods store and buy Egyptian cotton, almost silk like. Coffee and/or tea make good stains, very controllable.

I'm certain there will be other suggestions to follow....

- tasmanian and LFrankCPA

Thank you twintrow. I did look at that but some one needs to go back and up date the links. About 80% don't work any more. I was going for full rigged full sails. Can you do that in paper? 1/8 scale

Im sure this is old hat to the expert modelers but passing on that knowledge is needed by the next generation of builders

- JerseyCity Frankie

I make sails for models in scale 1:75 with seams of the cloths sewing marked with single thread ( courtesy of Admiral ). For models in scale 1:100 I use computer printing of cloths lines and reef bands on thermal transferring paper for ironing on to sails fabric . Sails leech, head and foot ropes are fixed in its place with use of textile adhesive .

Material for sails I prefer is old bed linen many, many times washed .

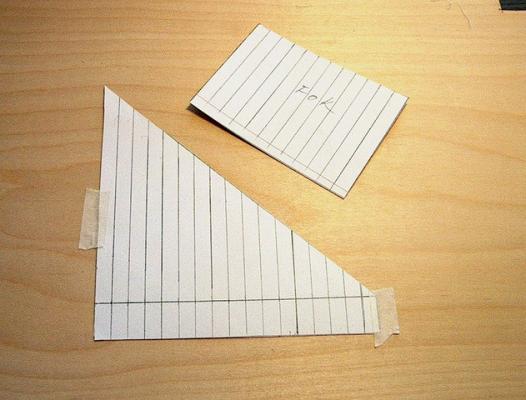

Work step by step

1.Make paper stencil for each sail and check it’s dimensions on your model.

2.With soft pencil transfer all lines in to fabric – add stripe 5-7 mm around

sail edges.

3.Make all necessary lines on fabric using sewing machine and thin thread with light brown or beige color.

For sails with thermal transferring of line any sewing is not necessary.

Cut of sail shape.

4. Fold the edges stripe to reverse side of sail and apply textile adhesive

5. Put sail on flat surface protected against glue adhesion ( wax paper )

and fix it with pins and nails for forming clews.

Using textile adhesive attach thread around sail and form clews and cringles as necessary.

After adhesive excess removal from sail surface and final ironing your sail is ready.

Foto 1-10 Sail making Step by Step

Foto 11 HMS Speedy - printed sails

Foto 12 HMS Warrior - printed sails

Foto 13 Patern for printing sails for S/S Savannah

- Landlubber Mike , CaptainSteve , bhermann and 9 others

I wouldn't use paper. If you don't want to use cloth, use silkspan from a hobby shop that deals with the RC guys/gals. It comes in various weights and you'd probably need to acquire small amounts of several sizes to find which one works best for you.

- Elia and Canute

Mark "The shipwright is slow, but the wood is patient." - me Current Build: Past Builds: La Belle Poule 1765 - French Frigate from ANCRE plans - ON HOLD Tri ton Cross-Section

NRG Hallf Hull Planking Kit HMS Sphinx 1775 - Vanguard Models - 1:64

Non-Ship Model: On hold, maybe forever:

CH-53 Sikorsky - 1:48 - Revell - Completed Licorne - 1755 from Hahn Plans (Scratch) Version 2.0 (Abandoned)

Good stuff.

I have seen some members using silkspan and modelspan. Any thought on this material. I'm not familiar with thermal transferring paper. can you elaborate. How do you use textile adhesive with out making a mess? Is it diluted in any way?

The adhesive is not diluted , unwanted stains of adhesive on sails can be easily removed by scraping .

Thanks for outlining the step by step process you use. In my opinion, the thermal transfer is brilliant. I have been hesitating to start my sails for quite a while because I don't want to sew the seam lines (I think they would look too bulky) and I don't trust myself to be able to draw them evenly using pencil. You have certainly given me something to think about! I imagine transfer will be more durable than pencil - another plus for the technique.

Current build -- MS Bluenose

Future build - MS Flying Fish

"A ship is safe in harbor, but that's not what ships are for." - William G. T. Shedd

Guest Tim I.

Good stuff. I have seen some members using silkspan and modelspan. Any thought on this material. I'm not familiar with thermal transferring paper. can you elaborate. How do you use textile adhesive with out making a mess? Is it diluted in any way?

Silk span is easy to work with. PVA glue works well and any glue that moves outside what you are trying to glue will dry clear. Also Rubber Cement works well, if applied sparingly. Here are some sails I have done using silk span. Nothing to write home about, but my first attempts at sail making.

I use strips of silk span to simulate seams and sail detail and work them up in layers. You can also add bolt ropes and reef points to add more detail. I did not go into a lot of detail with these, rather kept them simple to work on my technique. Also if you use PVA a good idea is to press the sails between some parchment paper and heavy books while drying to prevent buckling or bubbling of the thin strips of silk span.

I hope this helps.

I like the look of the silkspan and the layering of the cloth details. What weight silkspan do you use?

Not quite sure on the weight. I just bought what my local hobby store has. This Silk Span in my pictures is the "SGM White".

Hope this helps,

A question about silkspan. Can it achieve the draped and folded look of clewed up sails? Or will it be too stiff? I want to show my ship in the process of reducing to battle sail.

Laissez le bon temps rouler !

Current Build: Le Soleil Royal

Completed Build : Amerigo Vespucci

Just saw this while looking for a source for Sig Silkspan, source of quote is the Stuntbarn an RC Forum:

"Title: Silk Span Covering

Post by: ericrule on October 22, 2012, 12:10:29 PM I just got off the telephone with Sig Mfg where they informed me that they will no longer have silk span available. At the present time they have only OO (Light) in stock and when that is gone they will no longer be able to obtain it.

According to the person I spoke to the company that supplied the silk span is out of business and they can not find any other supplier. Mike is searching for a new source but it does not look like he is having any luck."

So not sure if real or not....? But if true silkspan may not be around loong??

Just saw this while looking for a source for Sig Silkspan, source of quote is the Stuntbarn an RC Forum: "Title: Silk Span Covering Post by: ericrule on October 22, 2012, 12:10:29 PM I just got off the telephone with Sig Mfg where they informed me that they will no longer have silk span available. At the present time they have only OO (Light) in stock and when that is gone they will no longer be able to obtain it. According to the person I spoke to the company that supplied the silk span is out of business and they can not find any other supplier. Mike is searching for a new source but it does not look like he is having any luck." So not sure if real or not....? But if true silkspan may not be around loong?? Tom

That is what my local hobby store told me as well. That is why I bought out everything they had, for stock.

Oh noooooooooooooooooooooooooo !!!!! Say it ain't so.

Thank you all this is good stuff. I hope I can still get silk span I would like to try it out.

Landlubber Mike

Is there a difference between silk span and model span? I have a roll of model span, but haven't tried using it yet.

Current Wooden builds: Amati/Victory Pegasus MS Charles W. Morgan Euromodel La Renommèe

Plastic builds: SB2U-1 Vindicator 1/48 Five Star Yaeyama 1/700 Pit Road Asashio and Akashi 1/700 diorama Walrus 1/48 and Albatross 1/700 Special Hobby Buffalo 1/32 Eduard Sikorsky JRS-1 1/72 IJN Notoro 1/700 Akitsu Maru 1/700

Completed builds : Caldercraft Brig Badger Amati Hannah - Ship in Bottle Pit Road Hatsuzakura 1/700 Hasegawa Shimakaze 1:350

F4B-4 and P-6E 1/72 Accurate Miniatures F3F-1/F3F-2 1/48 Tamiya F4F-4 Wildcat built as FM-1 1/48 Special Hobby Buffalo 1/48

Citroen 2CV 1/24 - Airfix and Tamiya Entex Morgan 3-wheeler 1/16

Terminated build: HMS Lyme (based on Corel Unicorn)

On the shelf: Euromodel Friedrich Wilhelm zu Pferde; Caldercraft Victory; too many plastic ship, plane and car kits

Future potential scratch builds: HMS Lyme (from NMM plans); Le Gros Ventre (from Ancre monographs), Dutch ship from Ab Hoving book, HMS Sussex from McCardle book, Philadelphia gunboat (Smithsonian plans)

I believe its just a different brand butt lets let the experts handle that question.

For what it's worth I got a big roll of model span last year from CornwallModelBoats.

Steven, if you're interested in furled sails, I shared my techniques that I used on my Badger in a separate thread:

http://modelshipworld.com/index.php/topic/3944-landlubber-mikes-technique-for-furled-sails/

- 2 months later...

jablackwell

Those looking for SilkSpan can still find it at the Guillow model airplane homepage. It can be found under the spare parts section. Each model plane has a spare parts assortment, and the wing covering is an option for most.

U.S. Brig Syren - 1803 - Model Shipways - First PoB Build

Sopwith Camel F.1 - 1916 - Model Airways - Not a Ship! , Completed

Kate Cory - 1856 - Model Shipways - Second Build, completed

Sultana - 1767 - Model Shipways - First shipbuild, completed

There's more on using SilkSpan for sails in a new booklet by SeaWatchBooks, or as a new chapter in a new edition of Swan IV.

- EricWilliamMarshall

Be sure to sign up for an epic Nelson/Trafalgar project if you would like to see it made into a TV series http://trafalgar.tv

- 1 month later...

Jolley Roger

For what it's worth I got a big roll of model span last year from CornwallModelBoats. Steven, if you're interested in furled sails, I shared my techniques that I used on my Badger in a separate thread: http://modelshipworld.com/index.php/topic/3944-landlubber-mikes-technique-for-furled-sails/

Can you recall under what product name CMB was selling the model span?

I've been unable to find it on their site.

Samuel Pepys notes in his diary on 19 July 1667: "the Dutch fleets being in so many places, that Sir W. Batten at table cried, By God , says he, I think the Devil shits Dutchmen."

I can't find it on the website either. I'm fairly certain it was under building materials or something and listed as Modelspan. I looked at the packaging, and it had the Mantua name/emblem on it, but I don't see it under the Mantua fittings. Maybe email them and ask?

Thanks Mike, i'll send them a mail.

I am a passionate advocate of including sails on models so I am pleased you are making the decision to include them on your model.

I had a look at your Victory build log, those sails looks fantastic!

I think I will follow your method when I get to that part on my build.

Richard Griffith

Bluejacket Shipcrafters ran out of silkspan recently but they substituted model span which to me is the same material. I used it to added furled sails to Le Superbe. I am a very happy customer of BJ, not an employee.

- Landlubber Mike , Canute and MrBlueJacket

I'm just using old worn bed sheets for my 1/100 scale HMS Victory. Check out my build log which is really not much at all about building the kit and mostly focussing on how I am making the sails. I bet if you searched through all my comments on MSW you would find 1/2 of all my posts are having to do with sails or rigging. I am a passionate advocate of including sails on models so I am pleased you are making the decision to include them on your model. I don't think the thickness of the material is that big a deal as long as the texture of the weave is fine enough not to draw attention to itself. Many very convincing ship model sails have actually been carved out of wood. My build log goes into a lot of detail on these points but I will just set them out here again: Don't use pure white sails, this will look too stark and in fact actual sails were cream colored or very light grey.(staining with coffee is super easy and very effective) Don't sew the boltropes on, no matter how fine a thread you use, it will look out of scale. Just glue them on. Do include sail construction details like reef bands and reinforcing patches, these give a good texture and are realistic. Look at all the photos you can find of reproduction ships that resemble your ship and try to duplicate that look.

JCFrankie, thanks so much for your detailed log on your sail techniques. I went with furled sails on my Badger, but was planning on doing a mixture of furled and unfurled on my Pegasus and future builds. Your results are fantastic, and I will certainly bookmark your log for when I get to that point! I experimented with tissue and a few other materials as well, but ended up with cloth as well.

Once again, a big thank you!

- 3 years later...

Hi I am making sails for a large pond yacht which will of course become very wet , if I chose a material that becomes too wet and heavy that will cause problems,

what is the best material to use

for a large expanse of sail.

My pond yacht is 5ft long not inc

bow sprit.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

× Pasted as rich text. Paste as plain text instead

Only 75 emoji are allowed.

× Your link has been automatically embedded. Display as a link instead

× Your previous content has been restored. Clear editor

× You cannot paste images directly. Upload or insert images from URL.

- Insert image from URL

- Submit Reply

Recently Browsing 0 members

- No registered users viewing this page.

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild 237 South Lincoln Street Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful links.

- Articles Database

- NRG Home Page

- NRG Online Store

- Important: Our Guidelines

- Terms of Use

- Buildlog Index

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

Our Emblem ®

Nautical Research Guild ® and the NRG logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,999,236 & No. 6,999,237, registered March 14, 2023)

- Existing user? Sign In

- Latest Posts

- All unread content since my last vist

- Unread topics I have posted in

- Create New...

Colored Dacron Sailcloth

Was this review helpful?

You may also be interested in:

Submit your email address for special promotions and offers.

IMAGES

COMMENTS

Kevlar is costly and worth considering for racing sailboats and offshore cruisers. Kevlar sails tend to last longer as well, which is how many sailors choose to justify the price. Kevlar sails are available in multiple weave types, strengths, and thicknesses. ... 3D 'Load Path' Sail Fabric. Load path (or 3D) sails are a high-tech alternative to ...

Sailmaker's Supply. Your on-line source for knowledge, wisdom, Dacron sailcloth, Sunbrella®, thread, and all the marine fabrics and products you need to sew your own sails and marine canvas! From $6 card holders to professional tools and sewing machines, we have unique gifts to please even the most difficult-to-buy-for boater!

Polyester has for decades been the most commonly used sail fiber because it is strong, durable and relatively inexpensive. Woven polyester sailcloth is often called "dacron", in reference to the brand name given by DuPont to their Type 52 Dacron yarn, which was developed specifically for sailcloth and was the industry standard for years. Over the years other suppliers have introduced ...

All Purpose Dacron Sailcloth. SKU: 1020-P. Read Reviews | Write a Review. $17.92-$24.78 per yard. SELECT OPTIONS: Qty. PRODUCT DESCRIPTION: An all around good choice for mainsails and genoas, this fabric is made with high quality yarns and construction. It is tightly woven with inherent bias stability.

Ambesonne Nautical Fabric by The Yard, Sailing Boats on The Ocean Surfing Coastal Theme Marine Life Colorful Maritime, Microfiber Fabric for Arts and Crafts Textiles & Decor, 1 Yard, Teal Green. 4.4 out of 5 stars. 1,131. $14.95 $ 14. 95. FREE delivery Mon, Aug 12 on $35 of items shipped by Amazon.

Aramid sailing fabrics are available in different combinations of characteristics (elasticity, tensile strength, weight) that determine their application and price. ... With such combination of features, the main advantage of PEN sails is price: a boat owner can buy a set of sails with superior properties compared to polyester sails without ...

In the sailmaking industry there are sailcloth manufacturers and sailmakers. Precision Sails designs and builds sails using the top manufacturers of Dacron sailcloth, Nylon Spinnaker cloth, and rolled Laminate sailcloth. Even though all sailmakers have access to the same suppliers of sailcloth, many choose to only work with a limited number in ...

SALE - Nylon Ripstop Spinnaker Cloth. $10.75 $5.00 per yard. This was a special purchase of Nylon Ripstop Spinnaker Cloth in Orange, Raspberry (Pink) and Hot Pink. The Orange... View Options. Sailmaker's Supply sells a wide variety of Dacron sailcloth & nylon spinnaker cloth. We also sell tanbark sailcloth & polyester insignia cloth for boats.

Vintage Red Sail Boat Fabric, 42'' Wide NOS Sailboat Fabric, DR2 (451) $ 12.00. FREE shipping Add to Favorites Sailboat Nautical Textured Cotton Fabric in Sold by Yard (3.1k) $ 12.00. Add to Favorites DREAM BOATS - Sailboat Toss in Blue - Sailboats Boat Boats - Cotton Quilt Fabric - Quilting Treasures Fabrics - 24344-B (W4059) ...

Sailcloth. Sails made with synthetic fibers. Sailcloth is cloth used to make sails. It can be made of a variety of materials, including natural fibers such as flax, hemp, or cotton in various forms of sail canvas, and synthetic fibers such as nylon, polyester, aramids, and carbon fibers in various woven, spun, and molded textiles.

Natural fibers like cotton canvas, which are very rare now. Synthetic modern fabric like polyester fiber Dacron, the most common sail material. Lightweight fabrics like nylon, which is used for spinnakers and downwind sails. High-tech composite fabrics called laminates, which are used on racing sailboats.

Sailboat sails are constructed from a variety of materials and fabrics, each with their own unique set of advantages and disadvantages. Many are designed to provide resiliency from weather conditions that could include constant sunlight and wind abrasion, while still others offer optimal weight distribution and a greater degree of maneuverability.

COARBOR 12'x12'x12' Sun Shade Sail Triangle Heavy Duty Fabric Cloth Screen for Patio Garden Yard Deck Pergola Canopy Water Permeable & UV Resistant (Beige) 4.3 out of 5 stars. 259. $20.98 $ 20. 98. FREE delivery Mon, Aug 19 on $35 of items shipped by Amazon. ... Upholstery Nautical Fabric by The Yard, Anchor Sailboat Printed Decorative Fabric ...

Tollfree: 1-877-374-SAIL(7245) Local: 228-522-3232. Fax: 228-522-3233

Nautical / Beach / Sailing. Nautical Fabric. Our selection of nautical, sailing and beach upholstery fabric by the yard features sailboats, lighthouses, sea life -- seahorses, sea stars, shells, fish, lobsters, crabs, cephalopods! We also have a large selection of nautical striped fabric that would be great for outdoor beach awnings and unmbrellas.

Sunbrella marine fabrics are excellent for boat interiors, exteriors, sails, headliners, and others. By choosing Sunbrella, you can bet your customers' boats will look great and that the fabric will live up to expectation. Sunbrella boat fabric has been a trusted choice for boaters across the world for more than 50 years.

Work step by step. 1.Make paper stencil for each sail and check it's dimensions on your model. 2.With soft pencil transfer all lines in to fabric - add stripe 5-7 mm around. sail edges. 3.Make all necessary lines on fabric using sewing machine and thin thread with light brown or beige color.

All Yekaterinburg Hotels Yekaterinburg Hotel Deals By Hotel Type By Hotel Class By Hotel Brand Popular Amenities Popular Yekaterinburg Categories More Yekaterinburg ...

4 ounce tightly woven sailcloth in bright colors for small boat mains and jibs, catamaran and windsurfer sails. 54" - 60" wide. Sold by the linear yard. Price: Natural (white): $13.43 per yard Colors: $17.92 per yard In an effort to reduce shipping costs, orders of 5 yards or less may be folded.

Rooms on Zagoorskaya, Yekaterinburg: See traveler reviews, candid photos, and great deals for Rooms on Zagoorskaya at Tripadvisor.

Nautical Sailboats Fabric - Sailing Adventures Icy Blue By Hipkiddesigns - Maritime Sailing Boats Cotton Fabric By The Yard With Spoonflower. (175.7k) $5.25. $7.00 (25% off) FREE shipping. Concord Fabrics Vintage Nautical Blue White Sailboat Themed Cotton Material NOS 1970's! #BV. (559) $13.99.

Guest House on Sheinkmana, Yekaterinburg, Russia - Sverdlovsk Oblast: See traveler reviews, candid photos, and great deals for Guest House on Sheinkmana at Tripadvisor.

14. Visit the Old Water Tower. Source: Photo by Wikimedia Commons user Dom kobb used under CC BY-SA 3.0. The old water tower is one of Yekaterinburg's oldest structures dating back to the 1800s and stands as a monument of industrial architecture. It is one of the city's endearing symbols.