- Multihull Sailor

- Real Estate

- Maintenance & Hardware

- Water Sports

The Best Boat Paints to Decorate and Repair Your Ride

No matter what type of boat you own, painting it and adding a bit of personal flair is always fun. Whether you choose to add a colorful stripe to the side or repaint the entire boat’s body, using high-quality, durable, and long-lasting paint is essential. Regardless of how you choose to paint your boat, you first need to decide on the right boat paint for your DIY project. To help you out, we've collected the best boat paints of 2024. The classic TotalBoat Boat Paint is our top pick, and you can check out our buying guide and other recommendations to learn more!

Our Top Picks For Boat Paints

- Best Overall: TotalBoat Boat Paint Shop Now ➔

- Easiest To Use: Duralux Boat Paint Shop Now ➔

- Quick Drying: Rust-Oleum Boat Paint Shop Now ➔

- Best Colors: Marine Coat One Gel Repair Kit Shop Now ➔

- 1 The Types of Boat Paint

- 2 Topside boat paint

- 3 Bottom paint

- 4 Wood boat paint

- 5 Tips When Using Boat Paint

- 6 Use the right type of paint

- 7 Follow the instructions carefully

- 8 Give ample time for the paint to dry

- 9 Choose the right colors

Can boat paint be used on all parts of the boat?

When should i paint my boat, does boat paint last forever, related articles, the best boat paints of 2024, best overall.

TotalBoat Boat Paint

Boats are almost always left exposed to the elements, which is why you’ll want a boat paint that will last you for years to come. The TotalBoat Boat Paint is a solid choice for any boat lover and has more than 20 colors to choose from, including aqua mist, sea foam, and fire red. The paint leaves behind a gloss that’s bright and is sure to stand out among other boats at the dock. This boat paint is incredibly easy and simple to apply. You don’t need to be an expert to give your boat a good coating with this seamless paint. Thanks to this boat paint’s bold profile and numerous color options, we’ve chosen it as our best overall pick, particularly for those who want to try painting their boat for the first time.

- Glossy and durable finish

- Up to 20 colors to choose from

- Self-leveling formula

- Not all colors are always available

Easiest To Use

Duralux Boat Paint

For many, painting a boat can be a risky endeavor. Owning a boat isn’t very cheap, and making a mistake during the paint job can lead to stains and errors that are difficult to fix. So, unless you can afford professional help, you may not want to take the plunge. Fortunately, painting a boat isn’t rocket science and with the help of the Duralux Boat Paint, it can be a fun and easy task. The paint only needs two thin coats with either a brush, roller, or airless sprayer. As long as you don’t paint your boat under the sun, you’ll get consistent and reliable results with this paint. The range of colors is a little bit limiting, but if you can get past that this boat paint is a strong first choice for novice boat owners.

- Very easy to apply

- Can be applied with various tools

- Long-lasting finish

- No warm color options available

Quick Drying

Rust-Oleum Boat Paint

Are you pressed for time or just itching to head into the water as soon as possible? The Rust-Oleum Boat Paint offers a quick and easy solution to all your problems. This paint dries in as little as one or two hours, which means you can start boating on the very same day you apply the paint. With a formula that retains its gloss over time, your boat will look as good as new for months or years to come depending on how you maintain it. While this boat paint only offers eight color options, it has a nice range of colors and most boaters are sure to find exactly what they’re looking for. If you’re okay with neutral color tones, such as sand beige or battleship gray, this fast-drying boat paint is a great investment.

- Dries very quickly

- Retains its gloss

- Great for use on fiberglass

- Not many color options

Best Colors

Marine Coat One Gel Repair Kit

With an easy-to-use formula and fast-drying properties, this gel coat will make your DIY boat project into an effortless task. Its versatile nature extends beyond boats, making it a perfect choice for fiberglass and other materials as well.

The real charm of Marine Coat One is its ability to create perfect color matches, bringing a fresh, vibrant look to your ride. Mix it up to get your preferred shade and watch as your boat wears a new, sparkling look. And it’s not just about aesthetics, it’s about enhancing durability too. So, if you’re looking forward to a sailing season with a boat that looks brand new and stands strong, this might just be your best bet.

- Easy to mix and apply

- Durable and long-lasting

- Provides a good color match

- Instructions are not novice-friendly

The Ultimate Buying Guide to the Best Boat Paints

When launching a boat renovation project, there’s a lot to keep in mind, such as boat carpets , boat seats , boat cushions , and more. But the most important element of all is boat paint. To renovate your boat, you’re going to need more than just regular old paint. Enter boat paint, a unique type of paint that is durable enough to stick to a boat in water. Boat paint usually leaves behind a glossy finish that gives your vehicle a nice tone that really pops when out on the water.

Because boat paint is made to last, you can expect a coating to stay in good condition for months or even years to come. How long your boat paint lasts will vary depending on how often you use your boat, where you’re boating, and how you store your boat when not in the water. There’s a lot to consider when buying boat point, so we’ve prepared a guide to help you out.

The Types of Boat Paint

Topside boat paint.

Topside paint is paint that’s applied on the top half of the boat, or the part of the boat that isn’t submerged in the water. While this type of paint can get wet, it’s used mostly for decorative purposes rather than protective purposes. You can get topside paint in a variety of colors and they can dry as quickly as one hour after application depending on the formula.

While topside paint may not be as protective as bottom boat paint, it’s still great for keeping your boat protected from harsh UV rays. Even your boat can feel the effects of the sun after weeks or months of exposure and a good coating of topside paint can prevent any UV damage from occurring on your boat’s hull.

Bottom paint

Bottom paint is a type of paint that’s applied to the bottom half of the boat, or the part of the boat that’s submerged underwater. This type of paint isn’t always visible as it’s under the water, but depending on how clear the water is you may be able to get a glimpse of it. Where bottom paint truly shines is in its ability to protect the boat from organisms in the water.

There are many critters in seas and lakes that can cause damage to your boat over time. Weeds and barnacles are some of the most common culprits. Bottom paint minimizes the chances of these critters from getting on your boat, ensuring it stays in good condition for much longer.

Wood boat paint

Wood boat paint is a type of paint that’s applied to wooden parts of the boat. These paints are not as long-lasting as other paints but are great if you want to preserve the wood finish on your boat.

Tips When Using Boat Paint

Use the right type of paint.

There are many types of boat paints that are used for certain applications. Before you think about the color or finish of the paint, first consider where you’re applying the paint. Are you trying to protect the bottom of your boat? Will you be adding color to the topside? Ask yourself these questions before buying so you can be sure to choose the correct type of paint, then you can choose the color.

Follow the instructions carefully

Paint is pretty easy to use and apply, but not all paints are the same. Depending on the formula of the paint, you may need to apply it a certain way or use specific tools for the best results. Even if you have experience painting walls, floors, or other surfaces, boats are a different thing entirely. You should always follow the instructions on the product packaging.

Give ample time for the paint to dry

Some paint formulas take overnight to dry, while others take only one or two hours. While you may be tempted to take the boat out for a ride as soon as the recommended drying time is over, it never hurts to wait one or two more hours just to be on the safe side. Unless you can comb over every inch of where you painted, it’s always a good idea to give the paint just a little extra time to dry. After all, the paint will be there for months or even years to come, so an extra hour won’t hurt.

Choose the right colors

Choosing the right colors for your boat paint can be a tricky task depending on how you want the paint to look. If you’re looking to simply paint over some scratches, it’s not too difficult to find the right color, but if you want to redecorate the hull that’s a different story. Think about what colors you like and how you want your boat to look. You may also want to consider the location itself, or where you plan on using the boat. These considerations may be trivial, but they’re worth thinking about if you want your boat to look nice in the end.

People Also Asked

No. There are certain types of boat paint used for specific parts of the boat, such as the topside or bottom.

If you feel like your boat could use a new paint job or if your boat has scratches from damage done by docking, it may be time to repaint your boat.

While boat paint formulas are made to last for as long as possible, these paints do not last forever and you will eventually have to apply another coat in the future.

Article Contributors

Sail magazine review team.

SAIL Magazine Review Team reports on best-selling products in sailing and boating. SAIL Magazine is reader-supported: When you buy through links on our site, we may earn an affiliate commission. Artificial Intelligence (large language models) may have been used in the research and creation of the content.

To ensure questions about product testing or a specific article are addressed, please contact [email protected]

How To Paint A Sailboat: A Complete Guide

Whether you’re new to owning a sailboat or not, you have likely put some thought into painting your boat yourself. It is important to keep your boat well painted as it can save you a lot of money in the long run. It can also save you a lot of money if you choose to paint your boat yourself.

Whether or not this is the first time you have painted your boat, you will still find this article useful. It has lots of tips and tricks for making sure you get the job done and get it done well. Hiring a professional may be easier, but there is a sense of pride and accomplishment in doing it yourself. If you use this article as a reference, you can’t go wrong.

Table of contents

Why is it important to paint your sailboat?

Painting your boat is not just an excuse to put some creative flair into your boat, it is an important process in keeping the boat safe. Safe from salt, safe from barnacles, and safe from damage. The paint acts as a vital protective layer, without it your boat will be vulnerable to all kinds of damage. If you have a wooden hull, this protective layer will keep the wood from rotting. It can also plug any minuscule holes that might allow sea life and salt to make its way into the body of the boat.

There is also, of course, the added benefit of having a boat that looks good . A boat is a point of pride and should be treated as such. Having a glossy looking boat is something to be proud of. Most boats are not painted far above the waterline, so it is even an opportunity to make your boat stand out. Some people also believe that painting a boat brings good luck. Unless of course, you paint it green, green is thought to bring bad luck. Whether or not you believe that is up to you.

What are the benefits of painting your boat yourself?

When it comes to painting your boat there are only two options. Hire a professional boat painting contractor, or bite the bullet and do it yourself. They both have their pros and cons, of course, but there is so much more to be gained by doing it yourself. First of all, painting your boat yourself is just as fun as it is difficult. Learning to paint is a valuable life skill that you won’t regret learning as early on in your sailing career as possible. If you can learn to paint your boat now, you will save yourself a small fortune in the long run.

Hiring a contractor is expensive, to say the least, it may be faster and easier overall, but the extra cost can make it simply not feasible. Or simply unappealing. If this is the first time you are painting your sailboat you will need to make a one-off purchase of all the equipment needed for prepping, painting, and finishing the boat. After these one-off purchases are out of the way, you will only need to buy paint and new rollers the next time. Even if you need to buy all the equipment brand new, it can be cheaper than hiring someone else to do the job for you.

How often do you need to paint your sailboat?

The general rule of thumb for painting your boat is that it will need bottom paint about once a year. This is when you will need to take the boat completely out of the water and give it a fresh new coat. If your boat spends all of its time in the water, it certainly needs painting at least once a year. The saltwater is so corrosive that you shouldn’t let your boat go without a fresh coat of bottom paint for more than 2 years. Even if your boat only spends half its time in the water, and the other half on land, you will find that its best to keep its coat topped up.

The top paint, or the above waterline paint, doesn’t need painting anywhere near as often. It isn’t in direct contact with the seawater so it simply isn’t going to get eroded down as much. The salty sea spray can still be damaging over time so this paint should be re-done every 3 years. It can be more or less frequent depending on use and personal preference. Some people like to do above waterline paint yearly, with the rest of their boat, but it isn’t necessary.

What are the best paints to use for your sailboat?

There are plenty of great brands of paint out there, in various colors and shades, so you won’t struggle for choice. There are some things you might want to look for in your paint . For example, you may have noticed that a lot of boats tend to have red hulls. This isn’t just a fashion statement, and while red is supposed to bring luck this isn’t the main reason either. The reason is that this red/orange paint is perfect for added protection along the bottom of your boat.

This red/orange paint is interestingly chosen because it is, of course, traditional; but mostly because of its copper. The copper is actually what gives the paint its red/orange color.

Copper is perfect for the bottom of your boat for several reasons. First, copper acts as a biocide. It stops worms from making their way into the hull if your boat is wooden. If it is metal or fiberglass, it still has the benefit of stopping barnacles and other sea life from attaching themselves deep into the hull of the boat. Copper is also strong enough to hold up to scraping.

Scraping is when you scrape barnacles and other sea life off the hull of your boat. Scraping is an important part of keeping your boat in good condition. It is important to check with the marina or port authority whether or not you are allowed to scrape. If you scrape without permission you may find yourself on the receiving end of a hefty fine. The reason is that they don’t want you introducing invasive species on to the marina floor. This is mostly a problem when you are coming from somewhere vastly foreign, not sailing from New York to Chicago for example.

How many coats of paint does a sailboat need?

When painting your boat it’s a good idea to think about how many coats of paint you are going to need. There is no exact number that is needed, it is mostly to do with how well protected your boat needs to be and how much time you have on your hands. Every coat takes time and attention to detail.

If you choose to do four coats of paint it is going to be time-consuming but very well protected. That being said, the minimum number of coats is two. One is not enough. If your boat only spends part of the time in the water, two to three coats are plenty.

If you are someone who lives on their boat full-time, or at least most of the time, you may want to do more coats. Three, maybe even four, might be ideal here. The reason is that first, your boat is going to experience way more wear and tear than one that is just an ocean part-timer. And second, taking out your boat (which is also your home) is a giant hassle. It is a tedious process, so doing it as infrequently as possible is probably in your best interest. More coats last longer. When you are sailing from place to place, finding somewhere to take your boat out of the water and perform this maintenance is inconvenient. You want to be doing it as little as possible.

What safety precautions do I need to take when painting my sailboat?

All paint can be toxic when inhaled. Even if it is “non-toxic” paint it is going to be harmful to your lungs. They aren’t meant to inhale anything but air, even non-toxic paint is going to be bad for them. This is why it is important to wear a face mask.

Your mask should be specifically for painting, not surgical masks or other cheap medial masks. They are not going to be strong enough, with a fine enough air filter. Whether you feel the need to wear eyewear is up to you during the painting process.

Before the painting begins, when you are scraping and sanding, it is a good idea to wear some goggles to keep debris and splinters out of your eyes. It is also a good idea to wear gloves. You don’t want to rough your hands up too much, they need protection from not only the paint but splinters and sharp pieces of metal.

Painting a boat can be dangerous work. Without taking the proper safety precautions you are putting yourself at unnecessary risk. This safety equipment costs just a few bucks and is equally important as any of the other tools needed to paint your boat.

What tools do I need to paint a boat?

There is more to painting your boat than just using paint and a brush . You will also need tough sandpaper , potentially an angle grinder or welder , paint, primer , brushes, paint rollers , paint thinner , and solvent. You will need to make sure you have all of these things before you start painting. You can pick any of these items up at a boating goods store.

It is a good idea to bring some buckets with you for filling with water, both for rinsing off your boat and your brushes. All of your safety equipment needs to be brought too.

If this is your first time painting your boat yourself, you may find you need to buy all of these things at once. That can be a lot to stomach when its all in one go, luckily, most of these tools and equipment can be reused. Besides, it is still going to be far cheaper than hiring someone to do it for you. All of this equipment is an investment in your boat.

How to paint a sailboat

Whether this is the first time you have painted your boat or not, you may find some of the tips in this next section useful. Painting your sailboat may be tricky at first, but over time you will get the hang of it. The problem with painting your boat is that it can be a very expensive mistake if you get it wrong.

It is important to read this guide carefully, take your time, and make sure you do the job properly. It may be slow going at first, speed will come over time. Once you have gathered all of your safety equipment and tools you are ready to get started.

The workspace

First of all, you need to ensure you have the right workspace. You cant paint your boat in the water so you are going to need to find somewhere to do your work. This is easy enough if you don’t live on your boat full time, take the boat to your house and do your painting on the driveway. If this isn’t an option because you don’t have space or live on your boat full time, you are going to need to rent somewhere. There are typically places affiliated with the marina that you can use. In some cases, these even come with a majority of the equipment you will need. This, of course, drums up the price a bit, but that’s unavoidable.

Your workspace needs to be well ventilated, or you risk making yourself very sick. Both from paint fumes, rubbing alcohol fumes, and fine matter from when you sand the hull down. This means painting your boat in your garage, if it even fits, is not always the best idea. If you do decide to paint outside, it is important to consider the chance of rain. Of course, your boat is pretty waterproof, but once you begin sanding rain might damage the wood if left to sit there.

Before you do anything else, it is important to look your boat over fully from top to bottom. You are looking for any bumps, scrapes, cracks and general damage. This damage is not going to be noticeable while the boat is in the water, so just before you paint it is one of the only times you get to have a close look. Once you have made note of all this damage, it is time to get to work repairing it. Depending on just how severe this damage is, you may want to get help with this next stage.

All of this damage needs to be repaired before anything else can take place. Painting over these damaged areas is just going to hide the problem temporarily, the next time it comes to painting you will find they are far worse. If you don’t deal with this now, they are going to snowball into complicated and expensive repairs.

After your repairs are done it is time to start sanding. This is very time consuming as you need to do it three times. Per coat. First, take the 600 grit sandpaper and make your way around the boat. It is best to use electrical tape to mark out a section at a time so you don’t keep losing your place. After you have finished with the 600 grit sandpaper, it is time to move on to 800, then 1200. This process is important so you will be painting on as smooth a surface as possible. It is then a good idea to wipe the surfaces of the boat down with a damp cloth to remove any of the dust and flakes of metal/wood. Otherwise, you end up painting over them.

You could wash the boat down with a hose but you want to avoid getting the boat unnecessarily wet now that the hull has lost its protective layer. If you are sanding down a boat with a copper paint bottom, you may find the sanding process difficult. Just do your best, it doesn’t need to be 100% perfect. It is important to get as much of the old paint off as possible. Your new paint won’t adhere to the old paint as well as it would to the boat hull itself.

Putting on a layer of primer is not 100% necessary but it is recommended. The idea is that you want your topcoat to adhere to the boat as well as possible, a layer of primer can help you do that. The primer needs to be painted on evenly all over the boat. If you only feel like doing below the waterline, that is fine too. It will save you a lot of time. Putting on the layer of primer is not the most time-consuming part, it is mostly the sanding down that you will have to do. You will need to sand down using the 600 grit paper, then the 800, then 1200. Just like last time. Your layer of primer needs to be as smooth as possible for the maximum adhesion.

Now comes the paint. It is recommended to do at least two layers of paint. One undercoat and one top. Some people choose to go as far as two layers of primer, two layers of undercoat, and three layers of topcoat. This is going to be very time consuming, remember you will need to sand down three times between each layer of paint. You can paint using a brush if you like but is far easier to use a roller. It is also far easier if you employ someone to help you with this stage. It could be your spouse, child, friend, or anyone. It doesn’t need to be a paid professional. It can take a long time to go through this process. Especially if you are effectively doing 8 layers of paint (including primer).

The fastest way to paint, especially if you are on your own, is to use a sprayer. They are easy to use, with a little practice. If you haven’t used one before you may find that you struggle to get an even coat. You should always paint in vertical stripes, not horizontal. Additionally, it is a good idea to have someone following after you with a small brush doing small touch-up jobs. Any unevenness will need to be sanded down and repainted. The whole painting process can take a week if you aren’t efficient.

Take pictures

It is a good idea to take pictures throughout the whole process. This is for future reference. For example, if you take pictures of the boat when you are assessing it for damage, you can compare them to after you have repaired or sanded the trouble spots down. If you cant see the trouble spots still, great! If you can, it will help you keep an eye on them after you have painted too. It’s a good idea to catalog all of these areas if they start to become regular problems you may want to have your boat looked at by a mechanic. You might also like to have a before and after picture for your blog, or just as a personal memento.

Hopefully, you now have all the theory needed to paint your boat. There is a lot more that goes into painting your boat than simply grabbing some paint and a brush. It takes planning, practice, and attention to detail. If you follow this guide you will have no trouble at all. If this is your first time painting your boat, don’t be disheartened if it takes a lot longer than you expected. Speed will come with time, it is far more important to get the job done right than get it done quickly. If you put the work in you will be painting like a pro in no time at all.

Related Articles

Daniel Wade

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Repairs and Maintenance

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

How To Choose The Right Sailing Instructor

August 16, 2023

Cost To Sail Around The World

May 16, 2023

Small Sailboat Sizes: A Complete Guide

October 30, 2022

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

June 15, 2022

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

Boat Reviews

- Boats Specs

- Marine Pros

- Boat Insurance

- Boat Warranties

- Boat Transport

- Boat Towing

- Marine Forecasts

Your Ultimate Boating Resource

Sailing Smoothly: The Best Guide to Selecting the Perfect Bottom Paint for Your Boat

Maintaining your boat’s performance and longevity is deeply anchored in the choice of the right bottom paint. It’s not just about aesthetics; it’s about creating a shield against marine life that can slow you down.

Dive into this all-encompassing guide to discover how the right bottom paint, tailored to your boating lifestyle, can make a world of difference.

The Vital Role of Bottom Paint

Think of your boat’s hull as a warrior in constant battle against underwater foes. Without bottom paint, it’s vulnerable to fouling, which can lead to reduced speed and efficiency. The secret weapon? Bottom paint infused with biocides that repel these unwelcome guests, keeping your hull sleek and swift.

Exploring the Seas of Bottom Paint Choices

Navigating the world of bottom paints can be like sailing through uncharted waters. There’s hard paint for the long haul, ablative paint that gracefully wears away with use, and even eco-friendly options that embrace green sailing. Each type has its unique strengths, so your choice should reflect your nautical needs.

The Copper Conundrum

Copper-based paints have long been the go-to for their fouling-fighting prowess. But as we become more conscious of our environmental impact, it’s important to weigh the effectiveness against potential ecological concerns.

Tailoring Paint to Your Boating Style

Your boating habits are the compass that guides your choice of bottom paint. Whether you’re leisurely cruising or racing against the wind, there’s a paint that aligns perfectly with your aquatic adventures:

Cruising Boats

With sleek and sturdy boats, their hulls coated in durable paint, resist the corrosive forces of time and tide. These vessels offer unwavering protection, allowing you to sail confidently through any weather conditions.

Racing Boats

For those seeking speed, ablative paints provide a slick and clean surface that is crucial for cutting through the waves. Their sleek, streamlined bodies sliced through the water with precision and speed. Each boat was coated in a shimmering layer of ablative paint, creating a smooth and clean surface that was essential for achieving maximum velocity.

Factors to Navigate When Choosing Paint

The waters you sail, the material of your hull, and even local laws are crucial markers in your journey to the perfect paint:

As you glide through the vast expanse of ocean, the type of water beneath your boat plays a crucial role in determining the ideal paint for your vessel. The crystal clear waters of a freshwater lake call for a different coating than the salty waves of the open sea. And even the laws and regulations of the local area can impact your choice of paint.

Hull Material

Selecting the hull material for your boat is like choosing a vessel as a sailor. The material you choose will play a crucial role in determining which type of paint will adhere best and provide optimal protection for your boat. Think carefully about your options, for the material itself can greatly impact the performance and longevity of your watercraft on the open seas.

DIY or Professional

Taking on a DIY project can be both exciting and daunting. Are you confident in your skills to paint your own ship, or will you leave it to the professionals? Consider the type of paint you choose–some are more forgiving for those without professional experience. As you set out on this endeavor, envision yourself as a deckhand navigating rough seas, armed with your chosen brush and paint, ready to transform your ship into a masterpiece.

Local Rules of the Sea

As you sail the open sea, always keep a vigilant watch on the horizon for any local regulations that may dictate your voyage. Pay special attention to any restrictions regarding copper-based options, as they may affect your journey in unexpected ways. Stay informed and navigate confidently to ensure smooth sailing ahead.

Final Thoughts

Your boat is more than a vessel; it’s a testament to your passion for the sea. Choosing the right bottom paint is a crucial step in ensuring it remains your faithful companion on countless voyages. With a keen understanding of the types of bottom paint and a thoughtful consideration of your boating style and environment, you can set sail confidently, knowing your boat is as ready for adventure as you are. Keep your hull in prime condition, and the sea will always welcome you with open arms.

RELATED ARTICLES

Overview of the 2024 sea-doo rxp-x 325, overview of the 2024 parker offshore 2900 cc, what your boat’s beam is and why it matters, power cats of 2024: ultimate guide to the top power catamarans this year, navigating the heat: 10 safety tips for a safe boat ride in the summer heat, latest posts, don't miss, our newsletter.

Get the latest boating tips, fishing resources and featured products in your email from BoatingWorld.com!

What type of wood is used for pier pilings?

What is the difference between a dock and a floating pier, what is the proper technique for pulling a beginner wakeboarder, what does ‘no wake’ mean on a lake, what is the difference between wash and wake, highs, lows, and tidal know-how: a deep dive into ocean currents, 10 essential tips for fishing near private property, the benefits of using a drift sock: guidance for anglers, lure fishing: secrets for imitating live bait and attracting fish, explore the untapped depths of america’s best bass fishing spots, outboard motor maintenance: tips for keeping your engine in top shape, the essential boat tool kit: tools every boater needs, diy boat building: 8 tips and tricks for building your own vessel, the art of miniature maritime craftsmanship: ship in a bottle, antifouling paints: a guide to keeping your boat shipshape, beginner’s guide to standup paddle boarding: tips and techniques, boating for fitness: how to stay active on the water, kayak safety: how to stay safe on the water, anchoring in a kayak or canoe: how to secure your small boat, overview of the 2024 yamaha 252sd, overview of the 2024 tiara yachts 48 le, overview of the 2024 bass cat jaguar sts, 2024 pursuit os 445: an overview, 2024 aquila 47 molokai review, 2024 sea-doo switch 13 sport review, gear reviews, megabass oneten max lbo jerkbait review, fortress anchors fx-7 anchoring system review, fortress anchors fx-11 anchoring system review, fortress anchors commando anchor kit review, fortress anchors aluminum anchors review, stay in touch.

To be updated with all the latest news, offers and special announcements.

- Privacy Policy

Home » Blog » Sail » Boat bottom paint: choose the best antifouling paint for your boat

Boat bottom paint: choose the best antifouling paint for your boat

By Author Fiona McGlynn

Posted on Last updated: February 9, 2022

You’re perusing the chandlery looking for a gallon of boat bottom paint (a.k.a antifouling paint). You just want to get in, get out, and get on with painting your boat.

But you reach the paint aisle and are awash in choices and confounding terms : hard modified epoxy, premium ablative, water-based, photoactive, thin film … The shop assistant suggests one paint, but your marina neighbor swears by another brand.

You’re feeling defeated. What happened to the good old days of slapping on some tar with a paintbrush and calling it a day?

Welcome to the convoluted (and at times highly controversial) world of marine boat bottom paint!

Fortunately, antifouling paint is not all that complicated . We’ll walk you through the different types of paint, help you choose the right bottom paint for your boat, and list the best boat bottom paint brands in each category.

Note: This post contains affiliate links. If you purchase a product through a link on this site we will earn a small commission. All opinions are our own. Thanks for your support!

What is boat bottom paint?

Antifouling paint is a specialized paint that is applied below the waterline to inhibit the growth of weeds, slime, and animals (e.g., barnacles and tube worms).

All antifouling paints are made from a combination of these four components:

- Biocide (deters living organisms)

- Resin (keeps the paint together)

- Solvent (determines application characteristics and clean up/removal methods)

- Pigment (color and viscosity)

The differences in paints are based on the sources and mixes of these four elements .

For example, the softness or hardness of a paint is determined by the type, combination, and quantity of resin used in the mix. More on the differences between soft and hard paints later!

Do I need bottom paint on my boat?

For boats kept in the water for more than a week at a time, it is necessary to apply boat bottom paint to prevent growth of marine life (fouling).

Why would you bottom paint a boat?

Boat owners apply antifouling paint to the bottom of boats that are left in the water all season because it reduces the growth of marine life (fouling). Fouling not only reduces a boat’s performance but can also permanently damage the hull.

- Fouling can dramatically reduce a boat’s performance. A fouled bottom causes drag, which reduces fuel efficiency, speed, and handling, and can even cause a boat to sit lower in the water.

- Fouling can permanently damage the hull. In extreme cases, where marine growth has been left unchecked for extended periods of time, the “glue” produced by fouling critters can damage fiberglass and wooden boats.

How long does bottom paint last on a boat?

Depending on the marine life in your area, how you use your boat, and how often you clean your hull, you may need to apply antifouling paint anywhere from once a year to once every three years .

When should you bottom paint a boat?

Bottom paint may last one to three years, but you should check to see if it needs new paint, every year. If you see worn-through patches, flaking, blistering, corrosion, or any of the signs below, it’s time to repaint. Clean the bottom of your boat first, so you can see the condition of the paint.

• The paint has worn through. A common practice is to alternate boat bottom paint colors so you can clearly see when this has happened. • Flaking or blistering paint. When water gets under the paint (often around hardware) it can cause blistering and damage. If you see a fair bit of flaking or blistering, it’s time to repaint. • If you find yourself using abrasive tools and scrubbing to remove growth while cleaning your hull. Your dive service can also advise you on when it’s time for new paint. • If you notice performance issues , like reduced boat speed or handling and you have persistent growth on the hull. • Corrosion (if you have an aluminum boat). Aluminum doesn’t “rust”, though it does produce aluminum oxide which causes paint to flake off, exposing the aluminum underneath. • Your boat has been stored in the water for three seasons . Despite manufacturer claims to the contrary, most paint jobs don’t last more than three seasons.

A note on timing and temperature

Most boaters apply antifouling paint at the beginning of the season once temperatures have warmed up enough for the paint to dry. It’s important to know that paint will only dry under the right conditions (generally speaking 50-85 degrees F and below 65% humidity). It can be too cold, hot, or humid for the paint to cure, so read the manufacturer’s directions and choose your timing carefully.

Note that hard boat bottom paints lose their antifouling effectiveness when exposed to air so you would not want to apply hard paint in the winter and then store it out of the water for several months.

Types of boat bottom paint

Antifouling paints can generally be classified into three groups: s oft paints , hard paints , and hybrid paints. As mentioned previously, the difference between soft and hard paint is the type, combination, and quantity of resin used in the mix.

Ablative bottom paint

Soft bottom paint (a.k.a. self-polishing and ablative bottom paint) is intended to gradually wear away as water flows over the hull. As the paint gradually sloughs off, it exposes fresh biocide, preventing marine organisms from attaching to the hull.

- Reduces buildup of old paint (as it’s constantly wearing away) which means less sanding and expense when you go to repaint.

- Soft paints contain less copper but the ablating action means the copper is used more efficiently.

- Does not lose effectiveness when exposed to air.

- If the boat is docked for long periods (not moving) the paint will not effectively slough off and fouling will occur.

- Ablative antifouling paints are a poor choice for fast boats because higher speeds quickly wear away the paint.

Generally recommended for:

- Slow boats (e.g. cruising sailboats and non-planing powerboats) that are used frequently as well as boats that are stored out of the water for part of the year. While displacement boats may choose either soft or hard bottom paints, many boat owners opt for soft paints due to the advantages of lack of paint build-up.

Interlux’s Micron CSC

Pettit’s ultima sr40.

Hard bottom paint

Hard bottom paint ( a.k.a non-sloughing or hard modified epoxy paint) does not erode over time and instead, the biocide leaches into the water. Water will gradually penetrate the paint until the biocide has been completely used up at which point the hard paint is no longer effective.

- Great for fast boats (e.g. racing sailboats and powerboats) as their tough exterior does not erode with increased speeds .

- Can be “burnished ” (finely sanded and polished) to provide a fast and smooth surface .

- Often contain a higher copper content which means better antifouling performance.

- Can be scrubbed more aggressively than ablative paint when cleaning the bottom of your boat.

- Hard paints build up over time with each additional coat unless vigorously sanded back each year. Eventually, the paint may build to a point where it cracks and peels and the hull will need to be stripped back (a very time-consuming process).

Stripping back paint to gel coat is a multiweek paint job and one of the downsides to hard paints which build up over time.

- Fast boats (e.g. racing sailboats or planing powerboats) and boats that stay in the water year-round. Ablative paints won’t last long at high speeds and a hard burnished surface will be faster for racers.

Interlux’s Ultra

Pettit’s trinidad sr.

Hybrid bottom paint

Hybrid bottom paints (aka semi-hard ablative paints) incorporate many of the benefits of both hard and soft bottom paints into a single product. Hybrid paints are self-polishing (like soft paint) and release biocides at a controlled rate (like a hard bottom paint), but they can’t be burnished to a smooth slippery surface for smoothness and speed. They also have less buildup than a hard paint.

- Ablative action

- Releases biocides

- Less buildup than hard bottom paint

- Holds up to faster speeds

- Can tolerate haulouts and air exposure without loss of protection

- Can’t be burnished

Generally recommended for

- Highspeed powerboats

- Slower displacement boats

- A fast trailerable boat may be better off with no paint at all as hard paints don’t do well when exposed to air for long periods . If that’s not possible, a hybrid paint may be a better option.

Things to consider before buying bottom paint

There are a few important things you should consider when choosing a boat bottom paint.

What type of material is my boat’s hull?

Boat hulls can be wood, fiberglass, aluminum, and steel. It’s important to ensure that a paint is appropriate for your boat’s hull material.

For example, aluminum boats must use specialized aluminum-safe paint. The cuprous oxide in regular paints will result in galvanic corrosion and damage an aluminum hull. Aluminum-safe paints use alternate biocides like zinc and cuprous thiocyanate.

For the same reason, you should never paint underwater metal components (like a propeller) with cuprous oxide paints .

Examples of aluminum safe paints: • Interlux’s Pacifica • Pettit’s Ultima Eco

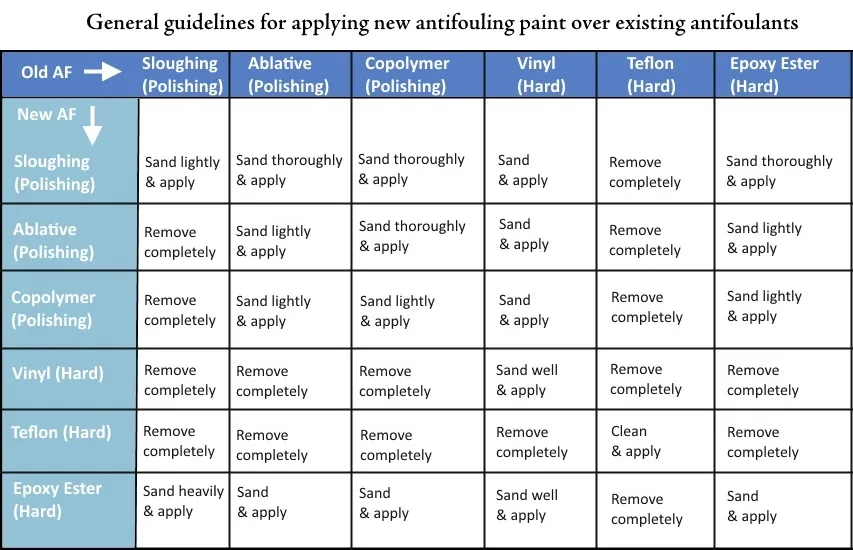

What type of paint is on my boat right now?

If you’re repainting a boat you must ensure that any paint you apply is compatible with the existing paint on the hull. West Marine , Pettit , and Interlux all publish compatibility charts for reference .

As a rule of thumb, soft paints can be applied over hard paints but hard paints cannot be applied over ablative paints . To switch from soft paint to hard paint, the soft paint should first be entirely removed.

But what if I don’t know what the old paint on the hull is?

If you don’t know what type of bottom paint is currently on the hull, you can at least determine whether it is hard or soft paint by rubbing the hull with a light-colored, damp rag. If the paint easily rubs off onto the rag, it’s likely ablative.

How often do I use my boat?

If you use your boat frequently, ablative bottom paint is a good choice because fresh biocide will be released as the boat moves through the water.

If your boat will be sitting for long periods, a hard bottom paint may be a better choice.

Where will I be using my boat?

There are many different types of fouling. Marine biologists estimate there are more than 4,000 known fouling species! Generally, these species fall into one of three groups: animals, weeds, and slime.

Factors like water temperature, water quality, nearby population centers, inflows from rivers and streams, the speed of currents, and the amount of sunlight will affect the types and degrees of fouling in your area.

You’ll want to choose a bottom paint that is suitable for the fouling in your area. As fouling can differ from one marina to the next, it’s a good idea to ask the dockmaster or boaters in your marina what fouling they notice and what paint they use.

For example, freshwater areas like the Great Lakes, don’t have to worry about barnacles, but they do suffer from slime. In this case, a thin film paint might be a good option as it offers a super slippery, low friction finish to prevent slime from attaching to the hull.

Examples of thin film paints:

Interlux’s vc offshore, pettit’s sr-21, do i plan on racing my boat.

If you’re looking for high-performance, opt for a hard bottom paint that can be burnished (wet sanded) to a shiny, slippery, and fast finish.

What are the environmental regulations in my area?

The word “biocide” literally means “life-killer”. The biocides used in anti-fouling paint are harmful to aquatic life (and not particularly healthy for humans to work with). It’s widely accepted that accumulated copper from boat bottom paint is detrimental to the marine environment .

In places like California and Washington state, this has led to new environmental regulations regarding the sale and use of boat bottom paints. Many locales also limit copper accumulation by prohibiting in-the-water hull cleaning.

In response to these health risks and environmental concerns, paint manufacturers have begun to offer more environmentally friendly alternatives, including:

- Water-based, low volatile organic compound (VOC) bottom paints

- Copper-free bottom paints containing photoactive materials and organic biocides.

These non-toxic, copper-free, and environmentally responsible alternatives to conventional antifouling paints are effective, kinder to the environment, and healthier for the person using them.

Examples of eco-friendlier bottom paints:

Interlux’s micron cf, pettit’s hydrocoat eco.

How many coats of bottom paint do I need?

For ablative paint , a single coat is sufficient for a season, whereas two or three coats of paint are recommended for multi-season use.

For hard paint , one or two coats is generally recommended. Additional coats will just add to more sanding down the road.

If in doubt, check the manufacturer’s recommendations.

How many gallons of bottom paint do I need?

The amount of bottom paint you’ll need depends on the size of your boat and how many coats you apply.

You can use this calculation to give you a rough estimate of how many gallons of paint you’ll need per coat.

Calculate the area you’ll need to paint:

[Length of your hull LOA (in feet) x Beam (in feet) x .85]

Then, divide it by the paint coverage listed by the manufacturer.

Area to paint (in square feet) / coverage (in square feet per gallon)

For example, a 35-foot sailboat with a 12-foot beam using a paint with a coverage of 400 square feet per gallon would be:

[35 x 12 x .85] / 400 = .9 gallons per coat

With this information in hand, you can now walk confidently into your local chandlery and make an informed decision on antifouling paint. It’s time to paint!

Fiona McGlynn is an award-winning boating writer who created Waterborne as a place to learn about living aboard and traveling the world by sailboat. She has written for boating magazines including BoatUS, SAIL, Cruising World, and Good Old Boat. She’s also a contributing editor at Good Old Boat and BoatUS Magazine. In 2017, Fiona and her husband completed a 3-year, 13,000-mile voyage from Vancouver to Mexico to Australia on their 35-foot sailboat.

Terms and Conditions - Privacy Policy

- 2024 BOAT BUYERS GUIDE

- SWS ADVENTURES

- Email Newsletters

- Fishing Boat Reviews

- Fly Fishing

- Marine Electronics

- Fishing Tackle

- Fishing Destinations

- The Bahamas Fishing Guide

- Boating Safety

- Ultimate Boating Giveaway

- Uncategorized

Choose the Right Bottom Paint

- By : Glen Law

- Updated: September 21, 2007

| If you don’t perform your own maintenance, it’s important to let the boatyard know which bottom paint to apply. |

Nobody likes to think about bottom paint, but everybody likes to think about his checkbook – or at least preserving its contents. Second to preserving fishing time, saving money – especially when it comes to boat maintenance – is something we’re all interested in. Even the guys who you’d think have better things to worry about than fuel consumption sit up and take notice when their choice of bottom paint can save them some serious bucks.

Case in point: When the J&T;, a 61-foot Viking, was delivered to Johnson & Towers, Inc. (the big marine diesel distributor in Baltimore), it sported a coat of standard Viking-issue ablative bottom paint. “We’d requested a different paint, but it just didn’t happen,” recalls J&T; skipper Dave Shinn. “They put on the paint they regularly use, the self-cleaning type.”

The J&T; fishes the Atlantic from New Jersey through the Caribbean each season, so water conditions and distances covered are extreme. The boat logs 1,500 hours a year.

“We left the original Micron CSC paint on, and we ran with that until it was time to repaint the bottom,” says Shinn. “Then we switched to the Interlux VC Offshore we had requested, the paint we were most used to.

“Once we switched to the hard paint, we noticed a big difference. Our speed stayed the same, but when we started comparing fuel logs from before the change to after we replaced the soft paint with hard paint, we discovered we had gone from 120 gallons an hour at cruise speed to 110 gallons an hour. And that’s not just on a single trip; it’s consistent with what we’ve recorded in our fuel logs over the past ten months we’ve been running with the VC Offshore.”

Return Investment

Granted, few of us run our boats 1,500 hours a year, or range as far and wide as the J&T; does. But all things are relative, and a nearly ten-percent savings on anything is worth paying some attention to. Look at it as return on investment.

Most of us who paint our own hulls, or who direct the boatyard to use a specific product, decided long ago which brand and type of bottom paint we like best, and we’ve pretty much stuck with it. But things change – water conditions, boat usage, even climate – and all of these variables have a lot to do with the type of paint that’s most efficient. Therefore, it pays to reassess from time to time the way you use your boat. Maybe you keep it in a different place than you did when you chose your paint originally. Maybe you’ve changed the species you most fish for or the amount of running you do. Maybe the quality of water you fish in has changed. The demands you make on your bottom paint can be as varied as the waters you fish and the species you seek.

While there are a number of bottom paints on the market from several major manufacturers, there are really only a limited number of choices you can make. Quite simply, there are “hard” paints and there are “soft” paints, each for a different purpose, and in those two categories there are weak, moderate and strong toxicity levels, which indicates the amount of the toxic ingredient, or biocide, that kills the things that want to live on the bottom of your boat. John Ludgate, vice president of sales and marketing for Pettit Marine Paint, explains some of the differences.

Ablative Vs. Hard

“There are two kinds of paint: ablative, which wears away by itself, and hard, which means the copper biocide leaches out and leaves the paint behind looking like Swiss cheese. At the end of 12 to 18 months you have to sand off this residue and apply a new layer of hard paint.”

Marine bottom paint comes in different varieties, each designed for a specific application or location.|

Ablative paint requires less maintenance, says Ludgate. “You don’t have to sand it to apply more paint. Like a bar of soap, the whole thing removes itself at a controlled rate, taking the organisms with it.”

Why you would choose one over the other has to do with the way the boat is used, as well as the level of maintenance you are willing or unwilling to take on. Another consideration, says Ludgate, has to do with the characteristics of the paint itself.

“Trailered boats and dry-storage boats require special consideration. Once you take a hard paint out of the water, the copper oxidizes and loses its effectiveness. Then it has to be sanded and repainted before you put it back in the water. With an ablative paint you don’t have to do this.”

There are advantages to both kinds of paint, and perhaps the biggest factor in choosing between ablative and hard is how the boat is used. “For high-speed running you need hard paint,” explains Ludgate. “At speeds of over 25 or 30 knots, ablative paints dissolve much faster. Fishermen who want to run 43 knots out to the canyons prefer a harder, more durable paint that will hold up to the wear of high speeds.”

Another benefit of hard paint is its “scrubbability.” In Southern California and parts of Florida, bottom cleaning is done on a regular basis by divers with scrub brushes, and a hard paint is essential for this kind of treatment. “Other guys will put on an ablative paint, which doesn’t build up on the bottom, so a complete stripping job is seldom necessary,” says Ludgate. “Pettit sells more hard paint than ablative, because that’s what most people have traditionally used, but the trend these days is more towards ablative as people recognize the benefits of less maintenance.”

How Powerful?

Once you’ve established the way you use your boat, and thus the kind of paint you need, you’ll want to consider the strength of the biocides based on the type and ferocity of bottom-fouling organisms that live in your area.

Jim Seidel, the assistant marketing manager for Interlux, explains a systematic approach to reviewing your particular needs. “Geography is a major consideration,” he says. “Different climates support different organisms, which require different paints. Florida is different than Maine. Tropical waters are much tougher on anti-fouling paint than are cold northern waters. In the tropics you need something that is a little more powerful and will hold up a little longer.”

Water type can vary within the same general locale, too. “Here in New Jersey, inshore and offshore are not the same,” says Seidel. “Some bays will be different, too. For example, the eastern side of the bay may be more salty, so on that side you’ll have more animal fouling, while on the west side there’s more slime fouling. It’s a salinity issue. And some areas, such as the mouth of the Connecticut River, have a lot of slime and grass growth – especially in the early spring after everybody puts lawn fertilizer down, so the paint can become overwhelmed. Another spot, Boston Harbor, was long notorious for high fouling because of sewage discharge that put a lot of nutrients in the water.”

The choice of bottom paint can affect performance and economy, depending on how and where a boat is used. |

These special demands, especially for slime control, have recently been answered by paint manufacturers through the addition of a booster biocide, particularly irgarol, a biocide recently approved by the EPA. Interlux calls it Biolux, and it’s available as a dual biocide in the company’s top-of-the-line paints, both hard and ablative. Pettit includes the same chemical in its premium paints, and designates it with the SR – “slime resistant” – moniker. By any name, it’s an additional biocide that, when combined with the regular copper additive, increases bottom protection in especially demanding conditions – the kind that are likely to change over time in response to climatic change and nutrient runoff.

Booster biocides are state-of-the-art in the world of bottom paint, but another trend under development is the non-metal, non-stick surface – a paint so slick that nothing can grow on it. This approach is not yet commercially viable, as the products that have so far been developed require weekly wipe-downs, a type of maintenance that many find too demanding. But it’s an approach that is likely to be developed over the next few years, so we may want to keep an eye on it.

So, what’s the “bottom line?” Every once in a while it may pay to reconsider the paint you’ve been using. Runoff from that subdivision up the street from your marina might just be making the aquatic environment a lot friendlier for nasty underwater organisms, so you may need a boost in biocide. Or, if you’re running longer distances or putting on more hours each year, a different type of paint may just be more economical. Hey, an annual savings of ten percent in fuel costs wouldn’t be too hard to take!

| ¿ New from Interlux is a high-performance, polishing, two-part bottom paint that the company says is the strongest, cleanest antifoulant in the world. Formulated with new Activated Biolux anti-slime technology, the two-part packaging (you simply mix them together) allows the antifouling ingredients to combine more effectively at the time of application. Available in black, blue and red, it’s designed to last up to 18 months with no mid-season scrubbing necessary, is easy to apply, cleanup is with soap and water, and it has very little odor. For product information, contact Interlux Yacht Finishes, Union, New Jersey; (800) 468-7589; www.interlux.com. – Ed. |

| ¿ , (800) 468-7589 ¿ , (800) 221-4466 ¿ , (314) 621-0525 |

- More Uncategorized

Everglades Boats

Boston Whaler

Contender 23Bay

New Electric Trolling Motors for Salt Water

Slow-Pitch Pollock

Selecting the Right Transducer Frequency for Deepwater Fishing

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

The Fastest Boat Bottom Paints: Antifouling for Speed

Whether you're racing your boat or cruising casually, everyone wants to sail faster. Is there a bottom paint that will make your boat sail faster? And is it right for you?

What are The Fastest Boat Bottom Paints? The fastest bottom paints are vinyl or Teflon based hard paints, which can be wet sanded and burnished to a smooth finish .

Maintaining a fast, racing finish with these paints requires more maintenance than a hard copolymer or a softer ablative paint. It is more maintenance, but it can make a big difference in boat speed.

On this page:

What slows you down, bottom preparation is everything, maintaining the finish, alternatives to hard and burnished, how much faster is it, what are your goals, racing vs. cruising.

In a word: friction. Friction causes turbulence and drag

Without requiring a degree in Computational Fluid Dynamics to explain it, a rough bottom is slower. More friction is slower - think about rubbing your hand across a carpeted floor versus a glass table top with a little oil spilled on it. Which is easier? Now imagine you're playing with a toy boat on either surface. If you push the boat, which one will be easier to push? Which might even keep sliding a little if you let it go?

Getting more into the science (still without the degree!), when fluids move over a surface there is a "boundary layer," the layer of fluid closest to the surface skin. When a hard surface moves through a liquid, molecules of the liquid get dragged along with it. This increases "skin friction" and causes drag. The faster something moves, the more drag.

If the flow of molecules in the boundary layer is "laminar", it is evenly spread and more calm. A "turbulent" boundary layer pulls more water with it and causes more friction and drag. A smooth bottom helps maintain laminar flow and reduce turbulence and drag as the boat speeds up.

These forces can be considerable if a boat bottom is not a fair surface, and the effect is more pronounced at higher boat speeds.

Given the power provided from your sails is constant, a boat with less drag will move through the water faster.

Spraying a layer of VC Offshore or Baltoplate on your boat will not make it instantly faster. To get the full benefit of a hard, fast bottom paint job the surface bottom must be prepared with care.

- Old incompatible bottom paint must be stripped. You can't put a Teflon based paint over an ablative or copolymer paint. It won't stay on.

- The bottom should be "faired." The aim is to create a smooth, curved surface with no bumps, dips or ripples. This is labor intensive and requires expertise and a keen eye to fair a hull.

- The bottom should be sanded smooth after fairing and before painting. Even if an orange is round and fair, if you spray paint it you will not end up with a smooth surface. You must start with a smooth surface.

- For a fast finish, spraying gives an even, smoother coating and reduces the amount of sanding time. Rolling hard bottom paint makes little sense because of the increased work from the rough paint application.

- Sanding and wet sanding is a must. Sprayed paint will still feel rough to the touch. For a fast finish sanding and wet sanding with up to 400 grit sandpaper will get results.

- Burnishing is a step even farther than wet sanding, and can give a mirror finish to a well prepared bottom.

Hard bottom paints designed for racing are not as effective at preventing grown as softer ablative paints or copolymers. They don't hold as much active antifouling, and it doesn't leach out of the paint or get refreshed since the paint doesn't slough off. And wet sanding and burnishing both remove some surface active ingredients.

In high growth areas, a racing finish with require constant maintenance and cleaning. When I raced my last boat, I had a diver come every week to clean the bottom and we dove on the boat ourselves at major regattas. You won't get hard growth quickly, but you will get slime buildup in very little time which can slow you.

You may not get two seasons from a coat of racing paint. If you don't, you'll want to wet sand it before the start of the season to ensure everything is smooth and ready again. The good news is that a properly prepared bottom is easy to re-spray and sand back to a good finish compared to the first time you do it.

What if you don't dive, can't clean your boat regularly, or don't want to pay a diver? Maybe you just want to go faster but aren't a speed-mad racer looking for every 1/10th of a knot speed extra?

Dry sailing for smaller boats is very popular. Fair the bottom and leave it unpainted or put on an underwater epoxy paint. As long as you don't store the boat in the water for more than a couple of days during a regatta there shouldn't be any growth. Most dinghies are dry sailed. Many smaller boats kept at clubs or marinas with a crane have this option, though there may be a cost to haul and launch.

If you stay in the water, a good choice is a hard copolymer paint. These are often referred to as "self polishing," as they smooth themselves with use as the paint sloughs off. Many of these are quite hard and can be carefully sanded to a smooth finish. Since they’re softer, you don’t want to sand through the paint. With proper preparation before painting, a sprayed paint job, and a little sanding, your bottom can be almost as fast as the high maintenance race boats.

Even without the sanding, a good bottom preparation before painting can give you more speed on passages. These paints are popular with long distance cruisers and people who use their boats frequently. You'll lose a little edge if you're racing, but you won't put yourself at the back of the fleet with it.

"What are you getting for your money" is a common question when preparing a boat for racing. The faster bottom and the newest sails won't win races for you if your crew can't tack or gybe and you can't spot wind shifts. You can lose the entire advantage of that quarter knot speed increase with a blown tack or a missed shift.

From personal experience, replacing a rough, coarse, orange-peel looking bottom with a polished and burnished bottom made a big difference. Both in my boat speed, and my wallet. It was expensive to do and expensive to maintain. But the boat was faster, and we were racing competitive regional events. The difference was most noticeable at low speeds and in light air.

There is not a lot of empirical data about how much faster a burnished Teflon bottom is over a well prepared copolymer paint. So the answer is "yes, it's faster," but with your boat, your budget, and your application there’s no way to predict that you may be 5% or 10% or half a knot faster.

To the casual club racer or cruiser, is it worth the time and money to prepare and maintain the fastest of possible finishes? It may not be; that's a question that only you can answer.

The best choice for a fast bottom comes down to you, your boat, and how you will use it.

- Are you a racer? If yes, is it weeknight club racing, or are you racing at higher level regional events against serious racers?

- If you cruise, how much maintenance are you willing to do to keep every extra fraction of a knot of speed?

- Where do you sail? Some areas have more aggressive growth than others. A sailor in the Great Lakes may get away with a hard bottom paint with less work than a New England coastal racer or a cruiser in the Caribbean.

- What is your budget for bottom preparation and maintenance? Are you willing and able to do some yourself?

- What us the current condition of your bottom? How ready is it for a top quality refinishing?

You will find very few non-racers who take the time and effort to apply the fastest bottom paints. The cost/benefit/effort analysis doesn't show a reasonable payback for what you get.

Most sailors aren't taking their boats to world-class regatta venues, they're taking off for weekends and vacations and maybe doing the club series on Wednesday nights or the annual regatta. Most of those boats are not going through the expense and effort for a competitive racing finish.

On the other hand, if you're racing in a competitive one-design fleet at New York Yacht Club Race Week or the San Diego NOOD Regatta, you can bet almost every boat in your fleet will have a smooth, wet sanded finish.

Leave a comment

You may also like, do i need to antifoul (bottom paint) my boat - sometimes.

Any time you buy a new boat, you get a work list as long as your arm. Bottom paint is expensive, toxic, and can be difficult to apply. It's an easy task to want to …

41 Sailboat Cruising Essentials for Long Trips

How to Calculate Outboard Motor Size for Sailboats

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sails and Rigging

- Maintenance

- Sailing Totem

- Sailor & Galley

- Living Aboard

- Destinations

- Gear & Electronics

- Charter Resources

- Ultimate Boating Giveaway

How to Paint Sailboat Decks

- By Tom Zydler

- Updated: March 14, 2013

Painting a sailboat

Janet Van Leuwen and Steve Van Wig own a Whitby 42. Looking at their beautiful, well-groomed ketch, you’d never guess it was built in 1982. The name on the stern, Lunacy , may be the only hint of the incredible amount of work that the couple has put into rejuvenating their boat. Bringing the decks and the coachroof top to their present glory was a large part of the project, as these tasks would’ve been on any glass boat more than 25 years old. This is how they did it. And frankly, this is how it should be done.

Before the couple could begin doing any prep work for painting, the deck hardware had to be removed. They needed access to tight spaces where the horizontal deck surface turned into vertical bulwarks, around the masts’ partners, near the windlass base, and so on. (They also removed the chainplates, which needed attention as a separate project.) Out came all stanchions, their bases, various padeyes, winches—anything and everything, in fact, that could obstruct the power sanders required to remove the worn-down, cracking, original nonskid pattern. Steve then used silicon sealant to plug all the fastener holes that would be reused; silicon repels paint, so the fastener locations would be visible when they began reinstalling the hardware.

Donning breathing masks and kneepads, the couple spent days grinding the old surfaces with 80-grit discs. Using thick foam pads on machines running at high rpm prevented any gouging in the laminate. Smaller sanders (both round and square) helped them to negotiate tight turns; at times, they resorted to manual sanding blocks. Working with thickened polyester and epoxy resins, Steve filled several hairline cracks and dings. They then sanded this filler with 80-grit, then 100-grit, and finally 120-grit sandpaper to achieve a smoother surface before vacuuming up all the accumulated dust.

Next, to keep paint drips off teak handrails, the windlass, and the portholes, they masked these with heavy paper and tape. Right after the final wipe with a cleaning solvent, they took two days to roll and brush on two coats of epoxy primer, the base for the final topcoat. Over the next few days, the primed surfaces were sanded with 120-grit paper, followed again by vacuuming and hosing the resulting dust. Afterward, Janet cleaned all the surfaces with non-sticky tack cloths designed for multipart polyurethanes.

At this juncture, Steve identified and outlined the future nonskid areas, then spent a couple of days taping their inner edges with long-life 3M masking tape. At the corners, joining short lengths of tape on tight curves required meticulous care. After they wiped everything with cleaning solvent, they applied the first coat of multipart polyurethane to all the surfaces outside the future nonskid. Two more topcoat applications followed within allowable, 16-hour intervals. After sanding with 220-grit paper, dusting, using the tack rag, and wiping the solvent, they rolled and brushed on the fourth and final topcoat. The solvent-resistant, ultra-smooth, high-density foam-roller covers and quality brushes delivered the best finish. Working in the hot Florida sun required frequent additions of brushing reducer.

After allowing 48 hours to fully cure, they removed the masking tape. Fresh tape was then applied along the outside margins of the nonskid areas. All was ready for applying the nonskid coats. But first Steve spent a few days experimenting. He mixed his own color tints—too dark, and you couldn’t walk barefoot on the sun-heated deck; too white, and the deck glare was intolerable.

Also, he tested paint combined with various nonskid additives on scrap plywood; very coarse grit could damage human skin if a sailor knelt or fell on deck. He decided to combine equal amounts of coarse and fine grit. Significantly, this mixture prevented the coarse grit from settling down in the paint in lumps. On the big day, Steve and Janet mixed the activator with the paint base in a large container, added the correct nonskid grit, poured in the brushing reducer, and thoroughly stirred it all. After pouring small dollops within a taped area, Steve spread it out with a roller with Janet assisting, adding more paint or grit as necessary. She also wiped up Steve’s occasional paint drips with a solvent-soaked rag. The work went quickly and smoothly, though constant stirring of the paint/grit mixture was absolutely vital.

Twenty-four hours passed before heavy, late summer rain rolled in. By then, the paint had cured hard, and the coachroof was finished. They then repeated the whole operation to paint the deck. Nobody said rejuvenating a classic-plastic yacht would be quick or easy. But when the entire project was finished and Lunacy ‘s deck sparkled, the two sailors realized that all their meticulous efforts had been well worth it.

Steps:** 1. In preparation for the job, much of the deck hardware, including the stanchions, had to be removed. The remaining gear was carefully and completely covered and masked. 2. All the fastener holes were filled with silicon sealant, and the couple spent days grinding the old surfaces. Then Janet used a solvent wash to ensure a strong bond with the primer paint. 3. After dings and cracks were repaired and sanded, two coats of epoxy primer were applied. 4. Following another round of sanding, vacuuming, cleaning, and taping, the couple rolled and brushed on a fresh coat of Awlgrip topcoat. 5. After four coats of Awlgrip, it was time for the nonskid. First, Steve experimented with colors and grits. Once under way, he poured on a dollop of pre-mixed paint and spread it evenly. Note the paint stirrer, which was used to prevent the grit from settling. 6. Stirring frequently, to make sure the coverage was even in each masked area, Steve worked quickly and efficiently while Janet addressed small splashes with a solvent-soaked cloth. 7. Voilà! Once the masking tape was removed, the fresh decks fairly glistened.

What You’ll Need: • Hook-and-loop sanding discs, sized to fit the sander pads • Sheets of sandpaper of grits 80, 100, 120, 180, 220, and 320 • 3M masking tape in widths of 1/2 inch (No. 256), 1 inch (No. 2090), and 2 inches (No. 225) • Gerson synthetic tack cloths • Roller frames and roller covers, with phenolic cores: ultra-smooth, high-density 4-inch and 6-inch roller covers (available from Home Depot; for the primers and topcoats) and Yellow stripe 3/8-inch nap (from West Marine; for the nonskid paint mixture) • Good-quality varnishing brushes • Cabisil (colloidal silica) thickening agent for making fairing putty with epoxy or polyester resin • Plastic putty knives • Interlux Fiberglass Solvent Wash 202 (for cleaning surfaces) • M.E.K. solvent (for cleaning all brushes) • Disposable paper/plastic pails of various sizes • A dozen wooden paint stirrers • Interlux Epoxy Primekote • Awlgrip topcoat (with Brushing Reducer and brushing converter) • Awlgrip Griptex nonskid additive (fine and coarse grades) • Ryobi and Makita random orbital sanders • Ryobi 6-inch palm polisher (used with a foam pad as a sander in complex spaces) • 3M breathing dust masks, ear protection, and solvent-resistant gloves

Longtime CW contributor Tom Zydler and his wife, Nancy, plan on spending this summer exploring the coast of Labrador aboard their Mason 44, Frances B .

- More: boat maintenance , How To , maintenance

- More How To

Surviving the Storm: A Sailor’s Tale of Hurricane Lee

Best Practices for Boat-Show Shopping

Grease the Wheels of Your Boat: A Guide to Proper Lubrication

A Bowsprit Reborn: A DIY Renovation Story

Sailboat Review: Dufour 41

Storm-Tossed, Lobster-Blessed: A Culinary Cruising Tale

Minimalist Cruising: Georgian Bay by Dinghy

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Coppercoat: The environmentally sensitive antifoul choice *sponsored post*

Yachting Monthly sponsors the Chichester Marina Boat Show and Watersports Festival

Round the Island Race 2019: Entries open

Düsseldorf Boat Show 2019: Fairline announces yacht line-up

Düsseldorf Boat Show 2019: Bavaria to showcase its complete range of motoryachts

- Subscribe Now

- Digital Editions

Best boat paint: 9 of the best DIY topcoats for fibreglass, wood or metal

- Ben Meakins

Nothing improves the look of a boat quite like a fresh lick of paint. Whether your boat is wooden, steel or GRP, today’s easily applied boat paints can give your boat’s topsides a new lease of life

Nothing improves the look of a boat quite like a fresh lick of high-quality boat paint. Whether your boat is wooden, steel or GRP, today’s easily applied topcoats can give your boat’s topsides a new lease of life.

But it’s not quite as simple as slapping a coat of enamel over any surface. To get the best results from your boat paint, you need to put in the hours with sanding, priming, filling and fairing.

The good news is that the best boat paints available today are easier than ever to apply, and are formulated to give an excellent finish for the DIY applicator.

A roller and a brush are all you need for a good result, and with practice your boat will look hugely improved. Pay attention to the instructions and above all to the recommendations on weather, temperature and surface preparation and you’ll be well on your way to an excellent paint finish .