- Forum Listing

- Marketplace

- Advanced Search

- All Topics Sailing

- Cruising Under Sail

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Cruising On A Cal 20

- Add to quote

After reading the article in Sailing MAgazine about K.P. Chin sailing to Hawaii on a Cal 20 I feel very inspired. I am planning on a trip from Portland, OR to Mexico and Central America this next summer on a Cal 20. Anybody done anything similar on a Cal 20 or other pocket cruiser?? I would encourage anybody to read the article!!

Is there a reason that half the people here seem Hell-bent on trying to see the world via sailboat on $17.00 budgets? I really just don't get it, Kids. My advice is that blue water cruising and circumnavigating entails a boat of at least 30 feet, well built, a year to prep and practice on her, some well made gear, some research and a strict exercise program to adhere to. This "He did it on a Laser" crap is a recipe for possible disaster at the worst, but more probably at least utter disapointment most of the time. Just save up and buy the proper tool for the job. Like anything else.........

After all these years I am very sorry to find out that I was only fooling myself when I did trans Atlantic trips on 22 footers, 27 footers 30 footers etc. At the time I thought I was having fun. Willy, A 20 foot Cal is a little light for my taste. You might have problems carrying enough provisions because carrying capacity and the boats displacement are related. The heaver the boat the more weight you can carry is a general rule. Also the smaller boat doesn't work to windward in any kind of a headwind so you need to be very careful about your choice of route. And the usual caveats about preparing both yourself and the boat. Good luck and enjoy, Robert Gainer

Read John Vigor's "20 Small Sailboats to Take You Anywhere". He STRONGLY disagrees with you. Not everyone can afford a 50k+ for a boat. Maybe you're sick of young, capable people with big plans, personally I'm kinda getting sick of old elitist yuppies who think you need to be born rich to sail a boat.

Where did you get elitist yuppy? He didn't say you had to spend a lot of money on the boat, he just advised a larger one, some of which can be had for the right price, and some preparation, including a good exercise regimen...why the personal attack on someone trying to give good advice?

DJ- Hey sorry about that, I didn't mean it to sound so hostile. It doesn't seem like Rick was really trying to give any advice, just belittle me and discourage me.

Arbarnhart- I've grown up sailing with my dad. We've cruised the Columbia River, Puget Sound, and the San Juan/Gulf Islands very extensively. Yes, this will be my biggest trip to date, but I don't see any reason I wouldn't be capable of it. Thanks for the response! Willy

Rick, so I now know I'm not cool, cause I have no idea what go-heads are, lol

Just because others have done it... doesn't necessarily mean it is a good idea. A 20' sailboat is awfully small...and a Cal 20 is awfully lightly built for a trans-oceanic crossing. In the 20' range, you might look at Pacific Seacraft Flickas, which are probably a lot more suitable. Also, it would depend a lot on your experience... if you're very experienced, you might be able to make that voyage on a SeaSprite 22 or something similar... but you'd really have to know the boat, keep a good eye on the weather and be prepared to take your lumps when you get out there.

Willy, What about my second question: Are you talking about sneaking along the coast ducking into protected anchorages along the way? I would have a completely different opinion of that than a blue water cruise. In a few rare cases, a small boat can actually be preferable (some long stretches with inlets that are too shallow for large boats). But, some of the hairiest water around is inlets with tidal currents and skirting shore lines means there are always nearby shallows and/or rocks to get blown into in a storm. So, while I would have a different opinion, I have to admit I am not sure what it is. Also, I am not one of the more experienced sailors - this is more thinking out loud and repeating what I have read.

arbarnhart said: Willy, What about my second question: Are you talking about sneaking along the coast ducking into protected anchorages along the way? Click to expand...

Well, you two sure showed me right there. WTF was I ever thinking? The weather and the north-west coast of California is absolutely perfectly made for a Cal 20. That's why there are so many charter companies in Coos Bay.....

Even doing a coastal voyage down the west coast of the USA is going to be problematic in a Cal 20. Some of the worst stretches of water you can run into are along that way, with few ports of refuge and in many cases a bad lee shore situation... so heading out is often the best option... and in a Cal 20, I doubt you would be able to do that. In some ways, a trans-oceanic voyage can be less dangerous, since you tend to have fewer things you can run into, as well as fewer lee shore type obstacles in your way. One friend of mine has pointed out that the most dangerous part of a long voyage is generally the start and finish, as you leave and approach land. Boats do fine when they have water under them... less well when they have land to hit.

Sailingdog- Hmmm that's definitely something to think about. I'll just have to do plenty of research.

http://www.sailboatlistings.com/cgi...r=Cape Dory&view_records=1&sb=date&so=descend http://www.marinesource.com/boat_sales/pacific_seacraft_sloop_6410470.html

willyknuckle I am sure that the san juans could keep you busy for some time, make your focus smaller to begin with so that you can get a better grasp on what exactly you want to look for in a larger boat as well as the bare nessisities you will need.As far as ssmall boats go anyone who sailed around the world in a boat under 26 feet bought it brand new. Cal also made the 29-9 which a gentleman just recently sailed around the world in I believe it was a 60s model. Check out ready for sea by Tor Pinney. It has a great bare minimum list.I know for a fact you can buy a cal 34 for $10,000 bucks and some would dare to say take it anywhere.

i'll check that cal 34 out. thanks!

Thanks Rick! I hear those little Cape Dory's are great. P.S. I;ve seen AFI 6 times!

willykunkle said: Thanks Rick! P.S. I;ve seen AFI 6 times ! Click to expand...

you could always fly out to the east coast buy any old boat and take it to mexico via the intercoastal waterway. we used to sail a san juan 21 that i picked up for $2000 everywhere in the ditch, it runs from the hudson river to mex. and key west is on the way.

Here's an interesting montage of when things go unwell. (And no, I not trying to scare anyone, this just showed up on another board and the photography is quite good).......... http://photos.sfsurvey.com/sailH/index.asp Clicky on the first pic and it should go to full screen slide show mode. Very impressive photage...

What was the helmsman thinking taking the boat between the south tower and the shoreline in that kind of a break? Sticking between the towers on the GGB would have been much safer and very well may have avoided the incident. Even in nasty weather, there is rarely a break under the middle of the bridge due to the extreme currents and deep water. I've been in some nasty big swells off of Bonita Point and Diablo Point in an 18 footer and made it in under the middle just fine. This looks like mostly human error and bad judgement.

whoa that is scary!

Willy...I think you need a better sea boat...like the cape dory's...not necessarily bigger...for the trip you are planning. Unlike the East Coast there is nowhere to duck in on your section of coast when the weather gets nasty AND you will be battling currents against you. Another thought is to buy your boat in CAL and avoid the worst of the trip that way...get used to the boat at sea on the way to Mex and then make your "ocean" decisions from there. It is easier sailing TO oregon than from Oregon!

If there are any Alberg 22's around your area they are decent sea boats that are not too expensive...

Well, Tania Aebi did buy her boat new. Webb Chiles, IIRC, bought his Drascombe Lugger new as well... but I don't think that is true of everyone who has circumnavigated in a boat less than 27' long though.

While he did not circumnavigate, I'm fairly certain HM's Captain Bligh did not have a new long boat. I'm not really at all sure that he did that much of a thorough preperation for his voyage either. I'm reasonably sure he was a damn fine seaman. One might look up William B. Trescott's video on "How to Equip a Trailer-Sailer for Serious Cruising". Crossed the Atlantic in his and cruised all over Europe. On the way back he got a brief ride on the back of a sperm whale. Practical Sailor had a nice review of he and the video. His gel-coat looked decidely pitted, he didn't have a solar-stix, and so I presume his boat was not new. (g)

I thought you were going to say he didn't have a light displacement fin keel boat. All the best, Robert Gainer A believer that when young go small go now.

I co-own and rebuilt a Cal 20 on the Columbia, and it's a great boat, but I agree that there's better offshore choices that might add significant amounts of safety for not much more cost. Just a couple of weeks ago, my brother scored a Bristol 24 on Portland's Craigslist for $1,000. It's solid overall, with some work needed, but I don't think his overall costs will be more than $3-4k to have a safe and ready boat. I also met a Cal 25 owner who took it annually off-shore out of the Columbia River and up to Puget Sound and back. As you know, Cal 25s can show up for $1-2k as well. Good luck! Jim H

Rick, So wearing shower curtains is all the rage these days with the Linkin Park crowd?

Go-Heads? I thought they were called flip-flops!

- ?

- 174K members

Top Contributors this Month

Great choice! Your favorites are temporarily saved for this session. Sign in to save them permanently, access them on any device, and receive relevant alerts.

- Sailboat Guide

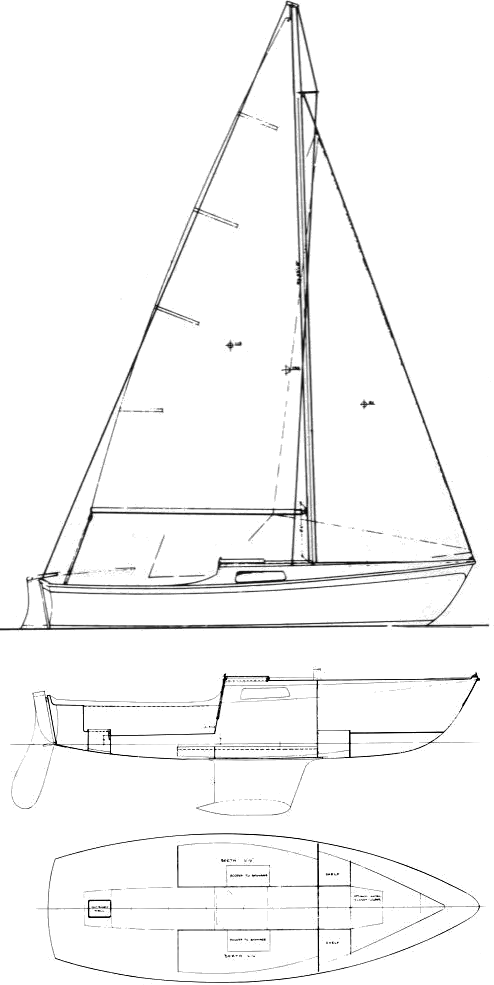

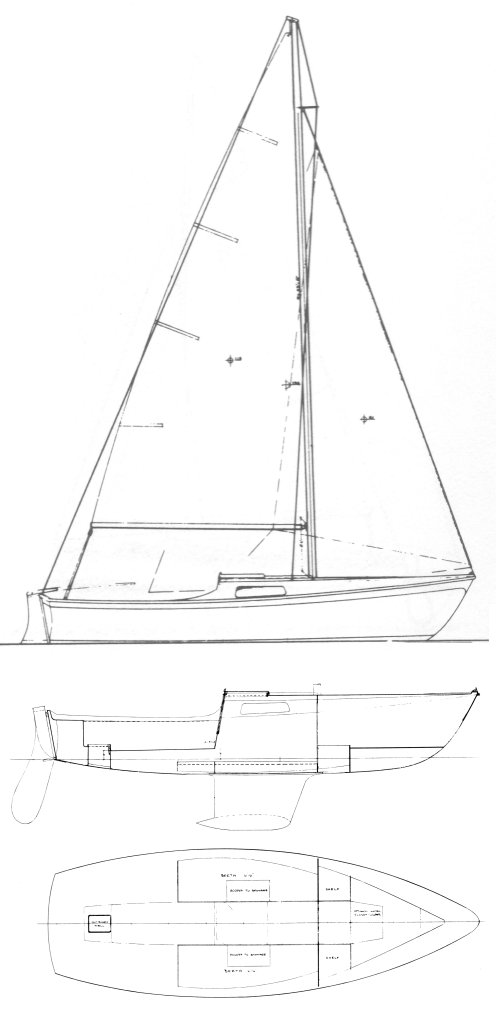

Cal 20 is a 20 ′ 0 ″ / 6.1 m monohull sailboat designed by C. William Lapworth and built by Jensen Marine/Cal Boats and Calgan Marine Ltd. between 1961 and 1975.

Rig and Sails

Auxilary power, accomodations, calculations.

The theoretical maximum speed that a displacement hull can move efficiently through the water is determined by it's waterline length and displacement. It may be unable to reach this speed if the boat is underpowered or heavily loaded, though it may exceed this speed given enough power. Read more.

Classic hull speed formula:

Hull Speed = 1.34 x √LWL

Max Speed/Length ratio = 8.26 ÷ Displacement/Length ratio .311 Hull Speed = Max Speed/Length ratio x √LWL

Sail Area / Displacement Ratio

A measure of the power of the sails relative to the weight of the boat. The higher the number, the higher the performance, but the harder the boat will be to handle. This ratio is a "non-dimensional" value that facilitates comparisons between boats of different types and sizes. Read more.

SA/D = SA ÷ (D ÷ 64) 2/3

- SA : Sail area in square feet, derived by adding the mainsail area to 100% of the foretriangle area (the lateral area above the deck between the mast and the forestay).

- D : Displacement in pounds.

Ballast / Displacement Ratio

A measure of the stability of a boat's hull that suggests how well a monohull will stand up to its sails. The ballast displacement ratio indicates how much of the weight of a boat is placed for maximum stability against capsizing and is an indicator of stiffness and resistance to capsize.

Ballast / Displacement * 100

Displacement / Length Ratio

A measure of the weight of the boat relative to it's length at the waterline. The higher a boat’s D/L ratio, the more easily it will carry a load and the more comfortable its motion will be. The lower a boat's ratio is, the less power it takes to drive the boat to its nominal hull speed or beyond. Read more.

D/L = (D ÷ 2240) ÷ (0.01 x LWL)³

- D: Displacement of the boat in pounds.

- LWL: Waterline length in feet

Comfort Ratio

This ratio assess how quickly and abruptly a boat’s hull reacts to waves in a significant seaway, these being the elements of a boat’s motion most likely to cause seasickness. Read more.

Comfort ratio = D ÷ (.65 x (.7 LWL + .3 LOA) x Beam 1.33 )

- D: Displacement of the boat in pounds

- LOA: Length overall in feet

- Beam: Width of boat at the widest point in feet

Capsize Screening Formula

This formula attempts to indicate whether a given boat might be too wide and light to readily right itself after being overturned in extreme conditions. Read more.

CSV = Beam ÷ ³√(D / 64)

Embed this page on your own website by copying and pasting this code.

Discover Related Sailboats

Twenty Small Sailboats to Take You Anywhere

John Vigor turns the spotlight on twenty seaworthy sailboats that are at home on the ocean in all weather. These are old fiberglass boats...

- About Sailboat Guide

©2024 Sea Time Tech, LLC

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

- Weekly Newsletter

California's Boating & Fishing News

Cal 20: A popular boat still in the race despite not being built

SAN PEDRO ― The California 20 was a boat in demand in the 1960s, but production on the popular sailboat halted in 1975 for reasons unknown. Cal 20s are still popular today despite being out of production and were on full display during a recent sailing event in San Pedro.

Cabrillo Yacht Club hosted the 56th annual Cal 20 Class Championship in Los Angeles Harbor, Sept. 22-24.

Alamitos Bay Yacht Club Commodore Chuck Clay, who won the championship in the past, hoped to win it all this year but finished in second place; he also placed second in 2016.

Clay said after coming across some waves, Ives took the lead. Ives ended up in first place his second year in a row.

The winds were steady for the first couple days of the race kicking up a bit towards the end of the second day. The winds took the championship up a notch on the final race day.

“Sunday started out at about 10 knots and got up to 13-14 knots,” Clay mentioned. “There was a lot of kelp. We caught kelp, and everybody got kelp which was very frustrating.”

The simple design of the Cal 20 makes this boat easy to rig and a breeze to sail. The boat’s design, which fits a two to three-person crew, provides sailing with comfort and ease.

C. William Lapworth designed the Cal 20 in 1960. The fiberglass sailboats were built at Jensen Marine Factory in Costa Mesa. Jensen Marine was bought out by Bangor Punta in 1965, and the factory relocated to Tampa Florida in 1981 and then relocated again to Massachusetts.

The production of Cal boats ceased all together in 1989.

“The Cal 20 is a great boat for One Design sailing,” Clay stated.

Stephen Ashley also competed in the three-day race and agreed with Clay.

“One great thing about doing a One Design fleet is it’s really easy to figure out how you are doing [during the race],” Ashley said. “With the Cal 20, it’s simple. If a guy is ahead of you, you’re losing. If a guy is behind you, you’re winning. That’s one of the things that make it fun.

“Chuck’s one of the best,” Ashley added. “They’re hard boats to do really well in because you have got to be right on your game to sail against someone of his caliber.”

Clay mentioned the Cal 20 is very affordable compared to other sailboats of this size.

A well maintained Cal 20 can be purchased or sold for around $2,000, according to Clay. A Cal 20 with upgrades can range in price from $6,000 up to $10,000.

One doesn’t necessarily need to own a Cal 20, however, to enjoy the sailboat.

Ashley teaches sailing classes on the Cal 20s in Long Beach. He is a member of Shoreline Yacht Club, trustee of a Cal 20, and treasurer of the SYC Sailing Foundation as well as an instructor.

The SYC Sailing Foundation is a 501(c)3 charitable organization and maintains a fleet of Cal 20s.

The boats are kept at the slips in front of Shoreline Yacht Club. The yacht club offers a place to teach sailing students in a classroom setting for the first day, and the harbor is where the students sail for the rest of the lessons.

Anyone can take the seasonal classes offered May through September even without a yacht club membership. Students can continue to charter the boats on a quarterly basis based on availability at a reasonable cost following the class and after passing a safety and skipper test.

One may not need to own or partially own a Cal 20 to compete in future regattas either.

Currently, the rules and regulations for Cal 20 competitions require the skipper to have at least one third ownership of the boat.

Ashley said the idea behind the ownership rule is to have people racing the boats who have an interest in the boats.

“We want people who are invested in the boats and have a long term investment in the program,” Ashley stated. “The downside [to the ownership rule] is that the group keeps getting older every year, and there are not a lot of new sailors coming into Cal 20s at the ownership level.”

Amending the bylaws to allow for more participation in Cal 20 regattas are currently being considered.

“Times have changed and participation is down,” Clay said. “So we’ve got to go with the changes to keep the class alive.”

Erin Rustigian photos

Share This:

- ← Next America’s Cup to be sailed in 75-foot monohulls

- Scheduling changes in store for Volvo Ocean Races →

Comments Cancel reply

Your email address will not be published. Required fields are marked *

Your Thoughts are Appreciated

Save my name, email, and website in this browser for the next time I comment.

Cal20PDX.NET

Rockin' good boats since 1961

Steve Rander’s Cal 20 Guide

Boat maintenance and everything you always wanted to know about your cal 20.

(Text below is work in progress to adapt the original to web content – click here for a PDF of the original book)

Your Cal’s Seaworthy Condition

- Structure of a Cal 20

- Fore and aft lower shroud attachments

- Upper shroud attachments

- Headstay attachment

- Backstay attachment

- Rudder attachments

- Backing plates

Your Cal’s mast and rigging

- Identifying your mast section

- Rocking masts

- Rigging wire inspection

- Turnbuckles and clevis pins

- Split rings and cotter pins

- Single lower shrouds

- Rigging a split backstay

- Controlling mast travel

- Your rig at the dock

- Boom vangs and out hauls

- How loose or tight should the rig be?

- Rig adjustment at the dock

Going faster

- Bottom preparation and paints

- Keel fairing (what is allowed)

- All those control lines

- Installing KT meters or depth sounders

- Fitting your engine plate (speed trap)

Going Racing

- Required on board Gear

- Cal-20 Bylaws

- Fleet 7 Bylaws

- PIYA Regulations,

- USCG Requirements

Maintenance

My cal has water inside.

- Companionway Hatch

- Cockpit Drain

- Gel coat, what is it?

- Cracks in my deck serious or not?

- Bottom blisters

- Fiber glass repair

Painting My Cal-20

Photos of Cal-20 Details

Internet Links and U-Tube Demonstrations

North Tuning Guide

A Classy Twenty-Footer

Cal-20 A Pocket Cruiser

Cal-20 Owners Manual

Preparing a Cal-20 for Racing

Structure of a Cal-20

The Cal-20 is made up of basically three fiberglass parts bonded together with multiple pieces of plywood bonded or mechanically fastened to support the fiberglass parts and keep the whole box section from twisting.

The hull liner is bonded in place and has flanges to take the plywood bunk tops and bulkheads which in turn are tabbed to the hull.

There are additional transverse bulkheads forward forming a chain locker and forward bunk support. There have been three different interior arrangements over the years the most notable difference is that the early Cal-20’s had a full main bulkhead and later boats had posts to support the deck beam.

This structure is more complex then it first appears and relies on the sum of its parts to properly carry and transfer the dynamic sailing loads. Failure of any of the components may not appear to make any difference but it does.

Loose bunk tops or bulkheads allow the box like structure to twist while sailing. This twisting may mean that your hull shape may not be optimal or the rig may be sagging and not developing the power it should.

Checking the structure:

Look for rotten plywood throughout the boat and replace it as soon as time and money will allow.

Look for loose tabbing on bunks and bulkheads where they meet the hull (even the one under the bunk) repair loose tabbing by removing the old, sanding both the plywood and hull surface with 80 grit and the bonding new tabbing ( usually 3 laminates of 6oz fiberglass cloth) back in place with epoxy. Don’t forget to look on the back side to see if the object you are bonding wasn’t bonded on both sides.

Look for cracks in the liner and if found grind back and repair the laminate. Look to see if the cracked liner doesn’t need some additional reinforcement.

Check the deck in way of hardware and especially chain plate areas for rotten wood in both the deck and hardware backing blocks.

If things are really shot plan for a big winter project but in the mean time do an area repair in the high load areas.

Check the rudder attachments to the hull to be sure that their backing blocks are good and the bolts are not loose (Mine have a tendency to work loose).

Check for cracks in the deck along side the main hatch runners. These cracks often are structural and allow water to migrate to the 1X2 that the hatch track screws into causing it to rot out.

See diagram pg.40

Look and see if there is a piece of plywood under the cockpit (between it and the hull or liner) giving it support. If not you run the risk of having cracks form in the corners of the companionway cutout. This missing piece of plywood will also allow the deck to flex when sailing meaning the Headstay tension will constantly change.

The Cal-20 came from the builder with two lower shrouds and what was thought to be a robust rig. We have over the years worked to get more performance from our boats and have changed things from what the original builder had in mind.

The first thing we did was remove the forward lower shrouds so the jib would move easier across the deck as we tacked.

The next thing we did was to add a split backstay and an adjustment tackle

And now we have loosened up the rig so we can move the center of effort forward and aft as we change directions from up wind to down wind.

All of these changes have come at a price and the price is that we are loading parts of the boat beyond what they were designed for.

To keep our boats together in one piece we have to upgrade the strength of the attachment points that hold our rig up.

The first is the aft lower shroud attachment point. This can be done by removing the bronze casting from the deck that the forward lower use to attach to and bolting it on the underside of the deck to the aft lower shroud attachment point. Next get a ¼” turnbuckle and a small chain plate and attach them to the underside and bolt the chain plate through the hull side.

See diagram for chain plate pg.4

The next is the Headstay. It turns out that we can put so much tension on the Headstay with the backstay adjuster that it is possible to literally pull the deck off the hull.

The fix is easy, just attach a chain plate to the bow so that some of the bolts go through the hull and attach the Headstay to that chain plate instead of the bronze deck fitting.

See diagram pg. 5

Keel Bolts and Keel Fairing

Let’s start with the bolts, if the keel is in good condition or you don’t want to deal with it at this time the bolts can be removed one at a time while the boat is on the hard.

If the nuts are very rusty (probably why you want to replace them) it is unlikely they will come off and it will take a die grinder and cut off wheel to make a slice down one side. You can then place a cold chisel in the slit and break the nut into two halves. If you are unsuccessful have fun cutting the other side of the nut.

Once the nut is off you can pound the bolt down and out the bottom. Some fairing putty will most likely come with it.

If I am just replacing the bolts and not taking the keel loose for some reason you can take a little caulking cotton and wrap it around the shank of the new 5/8” 316 stainless steel flathead bolt and smear Life caulk around it and the hole before tightening the nut.

When you have done them all check to see that they are all close to the same tightness, how tight? 150 foot pounds should be enough (a 50 pound pull on a 3’ breaker bar).

If this is all you are doing check the fairing around the keel and repair as needed remembering it is ok to fair it into the hull both fore and aft but not side to side. You may only put a ¼” radius at the sides.

Keel Fairing

Keel fairing can be nothing more then chipping a few spots and puttying in a few divots. For this epoxy putty is the best. If you are only dealing with a little rust try Pettit Rust Loc Primer. Remove any flaking rust and apply three or more coats following the directions on the can.

Major keel work is an undertaking and ask around before you start it. It is best saved for a winter project if you wish to sail in the summer.

Remove the keel and take it to a sand blaster. Have it blasted to bare metal (I am reluctant to say grey metal as some of our keels will have holes blown through them before they get to that point. Once blasted take it your work place immediately and epoxy coat the whole thing. Once the epoxy “B” stages lay it down on one side and smear epoxy putty on one side making it a pretty as you can. Grind down the surface when cured and finish the rough fairing. Sand again and roll the keel over. This side will need a sanding before coating then smear your putty on this side. Let cure, sand and putty again. Sand it again then stand it up and finish and fairing before you bolt it back on the boat.

Bolting the keel back on

Check that the keel is straight front to back (some aren’t) Adjust the bolt holes if needed. Check to see that the keel is not angled to the port or starboard side when it is bolted up and the boat is supported level side to side (may require washers placed under the flange between the hull and keel. If this is the case there is only one way to put the keel back on and that is with epoxy). If you need to epoxy it on come see me first and let’s talk.

If the keel is going back on with Life Caulk just be sure and use enough, I still like a little cotton on the bolt shanks. Clean up all the extra caulk and then putty in the fairing remembering not to fair the sides.

Cal-20 Mast and Rigging

What mast and boom are on my boat?

A good rule of thumb is that hulls 70-340 had Spar Craft masts and booms and all others had Jensen masts and booms. The Jensen mast is 2 5/8”x 4” and the booms were 2 3/8”x 3 ½”. Some early boats had tapered masts, those which came with them could use them until they failed but could not replace them. No other boats are allowed to use tapered masts.

The original mast basses were two piece cast aluminum with an aft hinge pin. The failure of these basses when mast rocking became popular lead to the rocking mast basses.

All rigging wire should be inspected often it is 1/8” stainless 1×19 wire with swaged end terminals. Great care should be exercised when stepping masts to be sure that the turn buckles are faced aft before raising the mast. Be carful about snagging wires while stepping.

If any wire end should look corroded or have a broken strand at the swag

Or a kink in the wire it must be replaced before sailing again.

The same goes for bent turnbuckles. DO NOT STRIGHTEN A BENT TURNBUCKLE. Bent turnbuckles must be replaced.

All split rings or cotter pins should be tapped to prevent being snagged and pulled out by some sheet line.

Most everyone has eliminated the forward lower shrouds to make tacking easier. Due to this change the aft lower shroud attachment to the deck must be reinforced (see sketches).

The addition of a split backstay will give the racer much better control of the Headstay tension but it also means that the Headstay attachment to the bow must be reinforced (see sketches).

Putting a split backstay on is a simple matter of installing an extra chainplate on the stern and having the backstay cut and re-swaged by your local rigger.

How high to cut it and what to use as a tackle is subjective (note not higher the 10’ above the deck) so look around at other boats.

The whole mast rocking, loose rig thing started in California where the Cal-20’s race without spinnakers. It improves both up and down wind performance and has been adopted here in Portland as the thing to do.

With that said be aware that it does increase the load in every part of the standing rigging when it shock loads. Take care to secure your rig when you leave the dock so it is not banging around. It is also a good idea to try and reduce the shocks when sailing and crossing a motor boat wake.

Boom vangs can be of any configuration as long as they don’t hold the boom up (No Kicker style vangs). The Cal-20 boom has so little extension beyond the measurement band the one needs to either rig an internal multi part purchases or side blocks at the end of the boom.

We find ourselves utilizing the Cunningham, outhaul, Vang, sheet and backstay to shape main as well as the backstay, halyard and sheets to control the jib so take the time to be sure all is in good working order and easy to reach.

How loose should the rig be? See rig adjustment at the dock for a starting place.

Most important and most overlooked is to PRE FLIGHT your boat before going sailing each time. Look at or touch every cotter pin, clevis pin, and shackle. Trace the standing and running rigging with your eyes to be sure that all is in order. By taking the time to do this you will be assured of having a great sail without fire drills or failures.

Rig Adjustment at the dock

Most Cal-20’s are setting up their rigs so that they can rake aft up wind and rock forward down wind.

Start with the rig loose enough and with enough toggles in the Headstay to allow the measurements in the drawing to be reached 28’ +/- 1” from the upper black band to the top of the transom.

Allow enough slack in the adjustable backstay to allow 29” 5” +/- 1” when the rig is shoved forward.

Now adjust the uppers and aft lowers evenly on both sides of the boat so that when measured out from the mast parallel with the water 5’ above the deck you can deflect the uppers out to 18” and the lowers out to 21”. The jumpers should be adjusted to be slack (IE no load on them).

Please note: While this allows the rig to move forward and aft when it is sighted up from the bottom and the boat is under sail it should still be straight side to side but have a slight curve fore and aft.

Sailing a Cal with this rig configuration may place higher stress loads on the rigging then would a normally snug rig so take extra care to inspect wire ends, turnbuckles, clevis and cotter pins. Tape things to prevent snags or items coming loose. Don’t fail to inspect under tape for wire failures.

When sailing in light air with motor boat chop it may be prudent to tighten things up to prevent the rig from slamming.

Shock cords or line can be used to prevent the rig from slamming while the boat is tied to the dock.

It also may be prudent to sail with the rig tightened up in heavy conditions.

These instructions are not an endorsement of the loose rig they are only given as an approximation of what other Cal -20 sailors are doing.

As skipper you are responsible for the safety and security of your crew and vessel.

Going Faster

Bottom preparation is one of the major ways you can make your boat go faster right after learning to sail better, owning new sails and being first over the start line.

Bottom preparation can take as little or as much time as you can put into it but trust me every hour you put into your bottom will pay off on the race course.

I will start with the idea that you are a top notch sailor and are going out to win the nationals.

Take the rig out of the boat, take the keel off and roll the boat over so you can work on the bottom by pushing down not up.

Take all the paint off and fix any and all blisters by grinding them out and epoxy/glass repairing them.

Now take a 1×4 about 6 feet long and put some 80 grit sand paper on it (this comes in rolls with sticky on the back) and sand the bottom front to back. You will find that a couple blocks of wood glued to the back so you can hold on easier will help as will knee pads. It is also a good idea to lightly spray a little black lacquer on before you start to sand.

What you should see if the bottom was perfect is all the black gets sanded off and the bottom is smooth with no bumps or dips. Trust me this won’t be the case. So mark the dips with a felt pen by outlining them sand the black out of the dips and mix up some epoxy and micro spheres into putty and fill all the hollows. Use a wide sheet rock knife or a piece of metal if you need something longer. Go home and have a beer then come back the next morning and spray a little black tracer again and sand. When you have come back about six days or so things might be getting close so you will move to an acceptable under water primer and apply a few coats. Now you get to sand with 120 grit paper. When things have gotten to the point that you can come out in the dark and shine one light on the bottom and move it here and there and like what you see you are ready to turn it right side up and put it back together.

The keel was touched on lightly under Keel bolts pg 6 but it will need a similar treatment as the bottom of the hull. Keep in mind that there are limits under the rules as to how thick you can make the keel so when you are all done be sure that at no point is it thicker then 1 ½”.

The Rudder is the only thing left in contact with the water so if you are not using one of the fiberglass rudders but a wood one you must be sure that your rudder profile will fit the Cal-20 shape. There is some variation allowed and you will need to cut your blank out to the profile that you feel is best (I like the one that has the least amount of sweep back as the helm feel is lighter). Now you can proceed to shape the foil you like but again there is a maximum thickness when finished which is 2 ¼” and a minimum weight of 255 lbs. When you get all done be sure you have epoxy and glass coated the rudder so it won’t absorb water and never leave it in the water when not sailing.

All that is left to talk about is the bottom paint. If you are headed to the nationals or are 100% into racing then the answer is NO BOTTOM PAINT.

The bottom should have been worked down with multiple coats of epoxy primer and sanded to ever finer grit until now you are down around 400 or 600 grit and all the scratches follow the flow of the water meaning none go the wrong way.

If you are not that zealous a smooth bottom with no bumps or blisters and a prep sanding of 120 grit in a fore to aft direction and VC17 or SR21 applied will be your fastest bottom.

The next fastest is a smooth bottom with no blisters or ruff spots and what ever paint you are using (if not one of the two above) applied as smoothly as possible and perhaps a light sanding with wet paper.

Now that you have the underwater part of the boat is in perfect shape we need to look at the sails.

If they are old they are slow and that can get to the point that if they are a few hard races old they are slow which is why there are rules as to how often you can buy new sails. So the best answer is to take the very best care of the sails you have. Use the newest ones you have on race day and use the older ones for practice. Remember you can only have one set on board when you race.

I will not go into sail set as there is lots of information around on that subject.

I will mention however that if the controls for adjusting the shape of your sails are not convenient and easy to reach fix the problems and move the controls so you can adjust them easily.

Just imagine that you are trapped to leeward at the start line and need to power up and pull a bit ahead and then alter the shape so that you are now pointing better then the boat above you as you pull ahead (now you get why controls are important).

Most all of us here have adapted the rocking mast and that is covered under Rig Adjustment pg.11

Knot meters and depth sounders. Any thing that you put thru the hull that protrudes into the flow of water will slow you down.

Should you put a knot meter in or not? If you do be sure that the housing does not stick down. Make a recess in the hull bottom so that when the thru hull is installed it can be faired in completely and only the impeller sticks down.

While a knot meter may be a great tool to help tune your speed another boat beside you is a better tool. So get your head out of the knot meter and look at the boats around you.

Depth sounders in Cal-20’s should never be put thru the hull but glued to the inside with silicone. They will read just fine as long as you didn’t glue it on top of a void in your laminate.

The only time I have found one of value racing a Cal is on the long distance races and then only of marginal help. It was better to look at the beach I was sailing next to and judge the slope and if the beach was curving out into the water ahead.

Now that you have the underwater part of the boat in perfect shape we need to look at the sails. If they are old they are slow and that can get to the point that if they are a few hard races old they are slow which is why there are rules as to how often you can buy new sails. So the best answer is to take the very best care of the sails you have. Use the newest ones you have on race day and use the older ones for practice. Remember you can only have one set on board when you race.

Most all of us here have adapted the rocking mast and that is covered under Rig Adjustment pg .

Knot meters and depth sounders. Any thing that you put thru the hull that protrudes into the flow of water will slow you down. So should you put a knot meter in or not? If you do be sure that the housing does not stick down. Make a recess in the hull bottom so that when the thru hull is installed it can be faired in completely and only the impeller sticks down. While a knot meter may be a great tool to help tune your speed another boat beside you is a better tool. So get your head out of the knot meter and look at the boats around you. Depth sounders in Cal-20’s should never be put thru the hull but glued to the inside with silicone. The will read just fine as long as you didn’t glue it on top of a void in your laminate. The only time I have found one of value racing a Cal is on the long distance races and then only of marginal help. It was better to look at the beach I was sailing next to and judge the slope and if the beach was curving out into the water ahead.

Speed Trap AKA Outboard Well

Here is one of the reasons that some Cal’s go faster then others and why we pull our boats out over the winter so we can work on them a bit.

The photo on the next page shows a poorly fitting bottom plate on my outboard well. The little (no matter how small) lip hanging down catches water and creates drag.

The easiest way to fix this is to first be sure the plate is in with the right end forward (I have an arrow drawn on the inside in felt tip marker).

If it is in right and a bit of lip is hanging down take a hand saw and cut the bond loose between the wooden frame on the inside and the fiberglass bottom plate. It may take a couple cuts to create a bit of a gap. Mix up some epoxy putty and squeeze it into the gap. Clamp the gap closed until the epoxy cures.

Larger problems may take more drastic action like a total rebuild. There are only three things to remember in your zealous quest for the perfect motor well cover.

- The cover must be removable without tools and it must pass water IE water poured in the well must flow out the bottom.

- When you get all done with your creation the bottom plate can not be thicker then 3”.

- You can not caulk the plate in place or putty up all the seams so it can’t be pushed out.

What ever you do to make your plate fit better will improve your performance.

When the perfect the motor plate is done you should not be able to see any difference in the bottom shape, only a thin line around the outer edge perhaps the thickness of a pencil line. This plate must be easily removable and it must drain water because if it doesn’t all your work will be for not as some measurer will not let you pass inspection. By the way I hope you did this work while you had the hull upside down.

The photo below shows a poorly fitting bottom plate on my outboard well. The little (no matter how small) lip hanging down catches water and creates drag.

Required Safety Equipment and Gear On Board

We race Cal-20’s here on the river in OCSA sanctioned races and as such utilize their Sailing Instructions and course charts. Additionally we are required to comply with the Bylaws of the Cal-20 Fleet and Local Fleet 7 bylaws. PIYA regulations and USCG requirements must also be met.

The following is a synapses of all the requirements and spell out what must be on board to legally race. There are a couple conflicts in the regulations which are spelled out at the bottom of the next page and which regulation takes precedence. The pages that follow are the complete rules and regulations.

Cal-20 By-Laws Require:

- Sails for Class racing shall be limited to a mainsail and a class jib. The cloth weight shall not be less than three ounces.

SAFETY EQUIPMENT

- All required government safety equipment must be carried. This includes a Type 1, 2 or 3 life preserver for each person; a bell, whistle or a horn; one throw-able Type 4 life preserver; and one fire extinguisher (if an engine or fuel is carried).

- Suitable ground tackle must be carried on board at all times. The minimum allowable ground tackle is an 8-pound Danforth anchor or its equivalent, with 10 feet of 3/16 inch chain and 100 feet of 3/8 inch nylon line.

Cal-20 Fleet 7 Additional By-Laws Require:

1. Sails, Spinnaker equal to PHRF Standard size and not lighter then 3/4oz nylon

(.05 poly is approved)

2. Spinnaker pole of 7’4” inside jaw to inside jaw

3. Class whisker pole may be used with jib only

4. Outboard engine meeting the requirements of PIYA Cat III.

OCSA Safety Requires:

1. All Boats comply with USCG requirements for recreational boating.

2. All Boats comply with PIYA category IV regulations

3. Sail numbers required on Main Sail and Spinnaker

4. Navigation lights after sunset

PIYA category IV requires:

1. Soft wood plugs for any below water opening attached with short cord.

2. Adequate paddle(s) or oars

3. A commercially manufactured anchor, 150’ of line and ½ the boat length of chain.

4. Yachts name on all float-able safety gear.

5. Navigation lights after sunset

6. A Bailer, bucket or bilge pump.

7. A flotation device with a whistle, reflective tape and the ships or crews name for every person on board.

8. Engine, tanks, vents, batteries, etc. meet USCG requirements.

9. A signed copy of the PIYA regulations on board.

USCG requires:

1. State registration

2. State numbers and sticker

3. Life jacket for all on board

4. Type IV throw-able device

5. Three day/night flares

6. Ventilation for areas which hold fuel tanks

7. One B-1 fire extinguisher

8. A whistle or horn

9. Navigation lights after sunset

10. A type I, II, III MSD if a toilet is installed.

The only conflicting requirements I have found are the old Cal-20 requirement for 100 ft of anchor line and PIYA’s requirement of 150’ (150’ takes precedence)

The PIYA requirement for paddle(s) or oars in Cat IV and the Requirement for outboard in Cat III and Cal-20 Fleet 7 By-Laws (outboard takes precedence)

My Cal Has Water In Side

The sources of water inside a cal just like any other boat are endless.

Some are obvious like water running down the inside of the hull at a window or piece of deck hardware.

Others are less obvious like the bottom rudder bolts or the laminations around the outboard trunk. The keel bolts are a possibility but then so is the main hatch, fore hatch and seat hatch. What about those cracks where the cockpit sides meet the cockpit seats or along the main hatch runners? These are all possibilities.

How do I stop the water from getting in? First you have to identify the source.

You must dry the boat completely and that may take putting your crew on deck next to the starboard shroud and healing the boat over a bit bow down and moping water out from under the forward bunk or out from under the cabin side bunks. Water will also find its way in between the hull liner and the hull so it is not easy to get it dry but you must.

Start at the top and work your way down. Are there any deck fittings that are leaking? If so fix them by removing them and then re-bedding them. See the U-Tube links on page 51.

How about the windows? Seethe comments on page 39.

Now let’s look at the cracks along the main hatch runners and the ones in the cockpit. These two sets of cracks are caused from stress and many do not actually leak but if the stainless hatch slides are loose odds are the fasteners or cracks are leaking. Smearing some caulk on them might help for a day or two but they will need to be ground back about a half inch on each side and a bit of fiberglass and epoxy used to fix them (be neat as these are hard areas to detail. See pg 40

The fore deck hatch if it is original will be leaking where it is screwed to the deck but also in the joints in the corners. Remove it, clean it up and take it apart. Then glue it back together again. Be sure to put some cellophane package tape on the deck in the corners and lay out some protection on the bunk as you will want to re-glue this frame in place so it will fit when you are done. When the glue has cured pop it off and then bed it in Life caulk.

The main hatch might have cracks in the bottom corners (check that there is a support under the cockpit see photos pg 49)

If there are cracks in the corners remove the wood edging, grind a taper in the laminate and put some fiberglass and epoxy to fill up the taper. Now bed the wood trim back in place. Be particular about the bottom piece as water likes to run down the drop board and find its way in the corners.

The cockpit seat hatch has problems of its own. The first is that there is no drip lip on the edges of the hatch lid so water likes to run right around and drip inside. Yes a gasket on the lip of the cutout will help but it really needs a drip lip see pg 41.

We are now inside and you are going to have to crawl (slither) back with your flash light and get all the way back so you can see the rudder bolts. Have someone else stand at the back of the cockpit so they are under water. Give it a few minutes and if they leak you will need to remove the fitting and bolts (either 3 friends on the foredeck while you do this or get it back on the trailer) When you do bed the fitting and bolts be sure there is a backing block on the inside of something like ½” plywood about 3”x6” and fender washers. If you don’t want to crawl back there in a few weeks use nylock nuts.

Now before you slither out of that little hole you are in look at the bottom of the motor well. Look all the way around it as they leak at the base sometimes. If it is leaking mark the area and haul the boat to do a fiberglass / epoxy repair. Look and see if the cockpit drain you put in from the front right corner of the cockpit is leaking. If so fix it. See pg 43

The next things to look for are any old thru hulls. If there are any get rid of them see pg 42. Yes this needs to be done out of the water. If you have a knot meter or depth sounder that goes through the hull check to se if they are leaking.

The only other sources of leaks (as long as you don’t have hull damage) are the keel bolts. While checking the keel bolts don’t jump to the conclusion that they are leaking just because there is water in the bilge. I now you have dried everything and you set there and watch water seems to ooze up around the bolts. That does not mean they are leaking it may only mean that you still have water trapped between the liner and the hull. Heal the boat over and check under the bunks. Do it to both sides and the bow down and then stern down and only then suspect the bolts. If I have fixed everything else so I know no water is coming in I might go away for a day and then mop out the bilge again and recheck.

Window leaks

Cal-20’s have had two different windows from the factory over the years of production.

The first was a metal framed glass window. Window leaks were from two sources on these windows. The first was a failure of the bedding compound. Simply remove the screws on the inside and have someone catch the port as you push it out from the inside. Clean the frame and cabin side up with a putty knife and solvent. Bed the port back in place with widow caulk, Life caulk or foam tape. DO NOT USE 3M 5200 to bed windows or hardware.

The second leak source was a failure of the gasket in the window frame itself. The frame can be taken apart and the gasket replaced with caulk.

The second window used in the Cal’s was a plastic window made by GO Industries. The only leaks associated with these windows is a bedding failure so simply remove the windows, clean them up and bed them again with Lifeseal. Do not use any other sealant on these windows.

If you have broken windows or just want new ones ( they are lighter then glass ones) the Go Industries windows are still made and they will fit in any Cal 20. The windows are made by Mark Plastics in Corona, Ca.

Gel Coat, Crazing Cracks, Blisters and Fiberglass Repair

Gel coat is nothing more then polyester resin with talc and pigments added, it has no reinforcement and tends to be brittle. When the hulls, decks and liners are made they are built in a female mold. The gel coat is sprayed in first and to get good coverage in all the corners it often becomes thicker in spots then it should. This extra thickness is one of the reasons that gel coat cracks. For years these cracks have been called crazing cracks and owners have been told they are non structural. This may not be true in all cases.

The cracks that most concern us are the ones along the sides of the cockpit seats, companionway slider tracks and the bottom corners of the cockpit or companionway.

If any of these cracks are leaking water they should be repaired. Repairs amount to grinding away the surrounding area of the crack and laminating fiberglass across the crack to bridge the weak spot. Once repaired paint or gel coat can be used to replace the color.

Blisters are caused by the fact that the hulls are laminated of polyester resin as is the gel coat. The molecular make up of polyester resin is a loose structure which will allow water vapor transfer.

Here is how it happens, water vapor penetrates the gel coat and laminate until it finds an air bubble or pocket. It may be that it finds a bit of dirt or contaminate, maybe some extra Cobalt or MEKP (used to promote and cause the cure of the resin to take place). When the moisture finds any of these defects it will form a gas pocket due to a reaction with the defect and a blister is formed.

When blisters are small they are nothing more then a nuisance and tend to degrade performance by disturbing the water flow past the hull. When they get big they can start to be structural.

What is small and what is big and how do I fix them? Small is anything from the size of a pencil eraser to the size of a quarter and big is any thing larger.

Repairs can be as simple as taking a small grinder to the bottom and grinding out each blister. This can be tedious work if there are a lot as you must grind a little dish into the hull so that the blister is all gone. In the case of small blisters an epoxy putty can be used to fill the areas back up to smooth. Larger areas may need fiberglass laminated to rebuild the strength of the hull.

In extreme cases the entire gel coat is removed, the hull is allowed to dry out and then a barrier coat is applied after the blisters have been repaired.

Fiberglass repair is not hard if the project is small, repairs to hulls after a port/starboard collision is another matter and best left to the professionals.

Small fiberglass repair consists of analyzing why it is required in the first place. The cracks at the bottom of the companionway opening caused because there was no support under the cockpit will not stay repaired if the cockpit is not supported so analyze the cause before you repair.

The fiberglass must be ground away into a taper on each side of the defect. The rule of thumb is the taper should be 20/1 or 40/1 in high load areas. What this means is the defect in a ¼” thick hull will require a repair area of 5-10” on each side of the defect. Care should be exercised to replace the laminate with a similar laminate to what is being removed. In short you can not expect to replace woven roving with a repair of mat.

All of the flat panels in or Cal-20’s are stiffened with marine plywood.

Long time contamination with moisture will cause it to rot. Take a look at the deck around the lower shroud chain plate attachments as they are often in the worse condition. If the backing block (another piece of plywood) is rotten the deck is probably rotten as well.

Let’s assume this is your only rot problem. It is possible to remove the deck fitting, pry off the backing plate and then tap around the underside of the deck with a small hammer and listen. The areas that are rotten will sound dead (like you have just tapped on a book and opposed to tapping on your desk). Mark the area with a marker pen and cut the plywood out using a chisel and hammer. Do a neat job of it and if when you are done the area is small (less the 4-6 square inches) cut a new piece of plywood to fit the hole and glue it in with epoxy.

At this point you have eliminated the rot and replaced it with a filler block. You need to now replace the backing block which will have to be thicker and bigger then the old one as you are trying to spread the load. I would use a piece of ½” plywood about 8”x12” or bigger if necessary.

If your repair cut out area was larger you will need to grind or cut a taper in the deck plywood and grind a taper on the plywood you are going to put back forming a scarf like you would in fiberglass repair except that it only needs to be a 12/1 taper.

If the deck in your boat is in very bad condition you will need to plan for a winter of it and take the keel off and roll the boat upside down. Strip out all the plywood and glue in new. Come talk with me if you plan on this project as there are some helpful hints.

You now know why it is important to fix leaks and to keep water out of the boat. It is also important to provide ventilation so moisture in the boat will dissipate.

One side note here and that is when storing your boat out of the water in the winter time be sure to not tarp it down tight but provide ventilation. Also the boat will need to be stored slightly bow down so that water will not collect on the cockpit seats and flow into the seat hatch.

Painting Your Cal-20

Painting is all about preparation, the better the preparation the better the job will be.

There was a long discussion earlier on bottom preparation for racing and the bottom paint is applied with a thin foam roller to keep the film thickness thin.

Painting the hull sides of your Cal or new stripes are similar to doing the bottom except that the sand paper used to prepare the surface is 220-320 grit.

If you are going to paint the hull sides take the rub rail off first so you will have a professional looking job. Mask out what you don’t want painted and do the job early in the day before the breeze comes up. We here at Schooner creek paint in a heated indoor spray area with filtered ventilation. We spray the paint to give a perfect finish. DO NOT Spray at home.

There is a nice video of rolling and tipping on U-tube see pg.

To do the nonskid areas of the deck be sure you get all wax or other contaminates cleaned first, then sand or scotch-bright all the surfaces to be painted to break any shine. Then do your final masking and clean up before painting. I have found it best if you are going to add some type of nonskid material to the paint DON’T. Take the can of particles and punch a bunch of holes in the top like a salt shaker, roll your paint on and while it is still wet shake the particles on. Do a good job of getting more on then can absorb into the paint. Come back the next day and vacuum up all the extra and then roll on another coat of paint. It will look great.

I am no expert on outboards but here is what I have learned over the years.

Buy the lightest motor for the power requirements you need.

The Cal-20 can be pushed along nicely with a 3hp short shaft outboard if you are using the well.

If you are mounting the motor on the transom be sure to put a big backing block on the inside and watch where you mount the bracket (check with other owners).

The trick with using the well is getting the motor and motor plate in and out and keeping the water in the well from swamping the cockpit while motoring.

The trick of motor in and out is most of the forward way must be stopped before the change. The same goes for putting in the plate. I have an arrow on the inside of my plate to tell me which way is forward. When I go to put it in I shove it down with the front edge up until the last second when I pull up quickly on the line between the plate and top cover. If you have ever done other you may have had a very exciting moment while the plate was trying to pull you down and through the motor well.

Just remember to slow the boat up when taking the plate in or out.

As for keeping the water from sloshing up into the cockpit the best solution I have found is a piece of 3-4” foam rubber cut just larger then the hole in the well with a “V” notch cut half way into the back of the foam so you can pull it around the motor as you shove it into the hole. The foam does a great job of stopping the water and is easy to deal with when storing the engine.

When ever you are going to put the engine back into the locker be sure that you have shut the fuel off, closed the vent and run the engine to get rid of any fuel still in the carburetor.

Watch your fuel to oil mix carefully if you have an old two stroke and carry spare spark plugs and wrench. Better yet change a plug once before going out this spring just so you know how to do it and have all the tools you need.

When putting the boat away for the winter drain the fuel from the tank and put in new fuel in the spring.

Internet links and U-tube demonstrations

http://www.youtube.com/watch?v=Gjyzc4c9JnE Painting by Rolling and tipping

http://www.sealsspars.com/index.html Steve Seals site for parts

http://www.pbase.com/mainecruising/rebedding_hardware&page=1 Bedding hardware to prevent leaks

http://express27.org/articles/stoppingleaks Stopping leaks

http://www.youtube.com/watch?v=SsoKAHU5xUw Fiberglass repair

http://www.westsystem.com/ss/fast-blister-repair-with-six1/ Blister repair

http://www.cal20.com/ClassAssociation/Bylaws/tabid/63/Default.aspx Cal-20 By-Laws

http://www.bassboatcentral.com/2strokecare.htm 2 stroke outboard care

http://sailingvoyage.com/photos/index.php/Cal-20-Restoration Restoration of a Cal-20

The Cal 20 is a 20.0ft fractional sloop designed by C. William Lapworth and built in fiberglass by Jensen Marine/Cal Boats between 1961 and 1975.

1945 units have been built..

The Cal 20 is a light sailboat which is a high performer. It is very stable / stiff and has a low righting capability if capsized. It is best suited as a racing boat.

Cal 20 for sale elsewhere on the web:

Main features

Login or register to personnalize this screen.

You will be able to pin external links of your choice.

See how Sailboatlab works in video

We help you build your own hydraulic steering system - Lecomble & Schmitt

Accommodations

Builder data, other photos.

Modal Title

The content of your modal.

Personalize your sailboat data sheet

Class Champs Keith Ives (L) and Chuck Stevens (R) (Fleet 1)

L to R: Scott Atwood, Chuck Clay, and Cathy Black-Smith (Fleet 1)

Jon and Debbie Thompson (Fleet 8)

Phil Soma (L) and Jeff Ives (R) (Fleet 1)

Kevin McCloskey (L) and Richard Welsh (R) (Fleet 4)

Fred Stevens (L), Mandi Smith, and Freddie Stevens (Fleet 1)

John Merchant (Fleet 1)

Mike Burch (driver) and Kenny Dair (crew) trim for speed (Fleet 4)

Renee Dereese (L) and Noah Stapleton (R) enjoy their trophy (Fleet 4)

Dean Wyer (left) and Mile Wilder (Fleet 4)

Margo Svilicich (L), Mike Svilichich (middle) & Dean Wyer (R) (Fleet 4

Rick McGregor (left) & Aaron Hall (Fleet 4)

Bryan Dair (L) and Steve George (R) (Fleet 1)

Cal20 Youth Movement at CBYC

Chuck Clay circa 1997

Ron Wood and Van Wilson circa 1998

Cal 20 Restoration 01

Cal 20 Restoration 02

Cal 20 Restoration 03

Cal 20 Restoration 04

Cal 20 Restoration 05

Cal 20 Restoration 06

Cal 20 Restoration 07

Cal 20 Restoration 08

Cal 20 Restoration 09

The Worldwide Leader in Sailmaking

- Sail Care & Repair

- Sailing Gear

- Sail Finder

- Custom Sails

- One Design Sails

- Flying Sails

- New Sail Quote

- 3Di Technology

- Helix Technology

- Sail Design

- NPL RENEW Sustainable Sailcloth

- Sailcloth & Material Guide

- Polo Shirts

- Sweaters & Cardigans

- Sweatshirts & Hoodies

- Accessories

- Mid & Baselayers

- Deckwear & Footwear

- Luggage & Accessories

- Spring Summer '24

- Sailor Jackets

- Maserati X North Sails

- NS x Slowear

- Sailor Jacket

- Sustainability

- North Sails Blog

- Sail Like A Girl

- Our Locations

- Icon Sailor Jacket

- North SUP Boards

- North Foils

- North Kiteboarding

- North Windsurfing

SAIL FINDER

SAILING GEAR

COLLECTIONS & COLLAB

COLLECTIONS

WE ARE NORTH SAILS

ACTION SPORTS

Popular Search Terms

Collections

Sorry, no results for ""

CAL 20 TUNING GUIDE

The following tuning guide is meant to be a good starting point in setting up your rig and sails. We are trying to achieve a setup that is fast in all conditions. Your new North Sails are designed for all around sailing performance.

The Cal 20 sails best with one or two degrees aft mast rake. While the factory stepped the masts in different fore and aft positions, we still need some sort of reference starting point. First, check that the black bands are in the correct position on the mast. Make sure the top of the bottom band is 30 inches above the deck and that the top of the upper band is 23 feet above that. Step the mast and then slide a 5/16 slug into the main sail groove and raise a tape measure up 23 feet to the top band. Pull on just enough backstay to make the head stay snug and measure back to the top edge of the transom on the centerline of the boat. 28 feet seems to be a universally acceptable starting point for the rake. Sometimes a toggle must be added to the forestay to achieve this much rake. If your boat has consistently too much helm upwind, the rake should go probably forward.

SHROUD TENSION

One fairly unique feature of the Cal 20 is the lower shroud placement. Since they are well aft of the mast base, they have a huge effect not only upwind on the side bend of the mast, but downwind as well since they restrict how far forward the mast can go. With the backstay snug, I measure down from a fixed point on the backstay bridle to the top of the transom.

Then I let the backstay off and make sure that my measurement reference point on the backstay can rise up at least 18 inches. This seems to be far enough forward downwind to be fast. At this point the lower shrouds should be tight. If the mast won’t go this far forward, the lowers must be eased and if the reference point goes past 18 inches, tighten the lowers till snug.

The next step is to make sure the mast is straight sideways. Mark your main halyard and swing it to a common reference point from one side of the hull to the other. Adjust the uppers shrouds so the measurement is even side to side.

The side shrouds are adjusted while sailing to windward. The mast should be straight in winds below 3 knots. From 5 knots up until the boat is overpowered, the mast should have a slight sag in the middle.

Once overpowered (usually above 10-12 knots), the uppers should be eased to straighten the mast and help flatten the main. Sighting up the aft mast groove with sail pressure on the rig and making slight adjustments to the turnbuckles is the easiest way to obtain the results desired.

Especially on larger, stiffer mast sections, the windward jumper should be loose when going upwind with no backstay on. The reason for this is that since the lower termination point of the jumper is at the spreaders, any tension on the jumper won’t let the mast sag to leeward and will depower the main if too tight. As the mast bends fore and aft from the backstay tension in the windier conditions, the jumper will start to take load and keep the tip from falling off too much.

The backstay should be tightened just enough to keep the headstay from bouncing too much. This requires constant attention. Too much backstay tension tends to bend the mast too much and open the main leech too much. A common symptom of too much backstay is not being able to point upwind. In puffy conditions it is best to play the backstay constantly to keep the boat both powered up in the lulls and flat in the puffs.

The boom vang bends the lower part of the mast allowing the main to be flattened. Once the boat is overpowered and you have to ease the mainsheet to keep the boat on its feet, the vang must come on pretty hard upwind. Note: Remember to ease the boom vang after rounding the windward mark because considerable stress is put on the middle of the boom when the sheet tension is released.

LUFF TENSION

Both main and jib should have just enough tension to maintain maximum draft position as follows:

- Main 50% aft of the mast

- Jib 35% – 40% aft of the headstay

Don’t overstretch the sail! Too much luff tension moves the draft forward, which is very slow.

BARBER HAULER – JIB SHEET

Probably the most controversial adjustment on a Cal 20 is the barber hauler or jib traveler positioning. We have prepared a chart to give you a good starting point for different wind and water conditions. The percentages relate to how far inboard from the outer rail to the hatch the positioning should be.

Be sure to watch that the leech is not hooking to windward due to excessive boom vang or mainsheet tension. Also, mainsheet must be eased when the boat heels more than 15 degrees. A Cal 20 must be sailed “on her feet”.

DOWNWIND SAIL TRIM

A few tips that will be helpful:

- Ease backstay and jib halyard so they match each other.

- Try to balance crew weight so there is a neutral helm.

- Watch that the boom vang is not on tight enough to hook the leech to windward.

- Keep crew weight as low as possible to avoid pitching from side to side.

Rolling your sails is very important, not just because they will last longer, but also to avoid getting permanent wrinkles. Rinse sails with tap water to remove salt and keep out of hot enclosed areas.

FEATURED STORIES

Pursuing perfection: tom gillard and the one design team, a visionary sail designer | gautier sergent (1977-2024), how to care for your foul weather gear.

- Refresh page

CAL 20 Detailed Review

If you are a boat enthusiast looking to get more information on specs, built, make, etc. of different boats, then here is a complete review of CAL 20. Built by Jensen Marine/Cal Boats and designed by C. William Lapworth, the boat was first built in 1961. It has a hull type of Fin w/transom hung rudder and LOA is 6.1. Its sail area/displacement ratio 20.03. Its auxiliary power tank, manufactured by undefined, runs on undefined.

CAL 20 has retained its value as a result of superior building, a solid reputation, and a devoted owner base. Read on to find out more about CAL 20 and decide if it is a fit for your boating needs.

Boat Information

Boat specifications, sail boat calculation, rig and sail specs, contributions, who designed the cal 20.

CAL 20 was designed by C. William Lapworth.

Who builds CAL 20?

CAL 20 is built by Jensen Marine/Cal Boats.

When was CAL 20 first built?

CAL 20 was first built in 1961.

How long is CAL 20?

CAL 20 is 5.49 m in length.

What is mast height on CAL 20?

CAL 20 has a mast height of 7.01 m.

Member Boats at HarborMoor

WELCOME TO THE 2024 CA OFFSHORE RACE WEEK

Registration is open for the 2024 CA Offshore Race Week, featuring coastal races racing down the California Coast in May/June 2024. The Notice of Race is posted.

CALIFORNIA OFFSHORE RACE WEEK NEWS

Sailonline is delighted to announce that we will again be partnering with the Encinal, St Francis, Monterey Peninsula , Santa Barbara and San Diego yacht clubs, and this year online-host two of their prestigious California Offshore Race Week, the CA 500 and the SoCal 300.

SAILONLINE RACE INFO >>

Dave MacEwen and Jeff Thorpe will offer a briefing on Spinnaker Cup preparations, tactics, weather routing and safety requirements at MPYC on April 9 starting at 530pm . This briefing is highly recommended for all skippers and crew who are planning to race in the upcoming 2024 Spinnaker Cup, or simply dreaming of doing the race someday. It would also be of interest to other racers and non-racers alike, including Spinnaker Cup volunteers.

The smallest boat takes the Series again. The 2023 California Offshore Race Week has concluded with Marc-Andrea Klimaschewski's Dogpatch 26 Moonshine, the smallest boat in the fleet, earning the title of overall CORW winner. For the second year in a row, the little boat makes a big splash.

Klimaschewski said "All of us are very happy about the great result and we are proud to be representing the Pacific Northwest and following in the footsteps of our good friends on Pell Mell who won the series last year in another small, wooden boat. Being a small boat, we always try minimizing our distance sailed. We also push the boat as hard as we can, the sails and loads are very manageable so if we overdo it on the gas pedal, that's usually an easy fix."

Register to join the Zoom Meeting presented by Quantum Sails. Join Jeff Thorpe from Quantum Sails, with Mike Godsey and Shea Gibson from Sailflow Weather, for in-depth forecasts, local knowledge, and expert tips. Ask questions and prepare for your race!

May 26, 2023 17:00

May 28, 2023 17:00

May 31, 2023 17:00

This link is for all three occurrences prior to each series race - register once and you’re in for all three. REGISTER HERE >>

The west coast's most bad-a** offshore race is just around the corner!

And the only thing as cool as racing the SoCal 300, is getting a gallery of epic Ultimate Sailing images (and video) afterwards. Plus the chance to be featured in the Ultimate Sailing Calendar, and leading boating publications! Contact Utlimate Sailing to reserve, space is limited.

GALLERY FROM PREVIOUS SOCAL 300s

CONTACT [email protected] 805-452-8853

All it took was a year of elbow grease and a little bit of TLC for Alex Simanis to get his newly restored Pt Bonita 27, Pell Mell , back into the water… and titled a winner. The smallest boat on the course for the duration of the 2022 California Offshore Race Week has proved that it is heart and skill that gets you first overall, not size. Simanis’ Pell Mell is the official winner of not just the SoCal 300, but the overall series winner of CORW.

Simanis commented, “The Spinnaker Cup was epic. We stuck with our plan of staying out and waiting for the new breeze to come - and it worked out well. The last 50 miles we did in about 6 hours and we came into Monterey on a nice angle and 25+ knots of breeze. For the SoCal 300, it was a beautiful jib reach to the islands. We thought it was going to be game on, but it was really light. We got stuck in the island and had to battle back and forth to find a lane. A bunch of the fleet moved more to the west and we ended up sneaking towards more of the east breeze that filled in. We were able to catch up to the 1D35 and J/111 and the bigger boats for the run. Our boat is pretty quick on the run, so nobody got away from us.”

On Saturday May 28th, 30 boats departed San Francisco on the 1st leg of the California Offshore Race Week, The Spinnaker Cup, 86 miles of downhill fun, from San Francisco to Monterey. In the midst and in the mist, an improbable contestant, that had been ignored, more than it had been sailed recently and much less raced. Originally built in the mid 80's by Dave Sutter, the Point Bonita 27' Pell Mell was designed to be more of a cruiser, with inspiration from the Dogpatch 26, without the hard chines below the waterline. Her ample room below decks makes things more comfortable for a midget distance racing ride.

Long sleeve wicking shirts, hats, vests and gaiters featuring the CA Offshore Race Week designs and logos are available through the Pirate's Lair online store .

MORE DETAILS || ORDER FORM

[email protected] 805-452-8853

Page 1 of 7 pages 1 2 3 > Last ›

SPINNAKER CUP San Francisco to Monterey May 25-26, 2024

COASTAL CUP Monterey to Santa Barbara May 27-28, 2024

SOCAL 300 Santa Barbara to San Diego May 30 - June 1, 2024

MORE CALIFORNIA OFFSHORE RACING

ISLANDS RACE

February 25-26, 2022 www.islandsrace.com

PUERTO VALLARTA RACE

March 10-18, 2022 www.pvrace.com

PACIFIC CUP

July 4 - 22, 2022 www.pacificcup.org

© 2014 - 2024 CA Offshore Race Week. All Rights Reserved. San Diego Yacht Club | www.sdyc.org 1011 Anchorage Lane, San Diego, CA 92106

Biggest Trailerable Sailboats

Last Updated by

Daniel Wade

June 15, 2022

Many sailboats up to about 27 feet in length can be trailered safely on American roads. These vessels are limited by weight, beam, and overall height.

In this article, we'll go over ten of the best large trailerable sailboats on the market. These vessels feature comfortable cabins, excellent sailing characteristics, and they all meet the requirements for towing on U.S. highways.

The best and largest trailerable sailboats are the Cal 20, the Catalina 22, the O'Day 240, The Islander 24, the Moore 24, the Cal 25, the Helms 25, the MacGregor 26, and the Nor'Sea 27. Most of these vessels can be towed behind a well-equipped truck or SUV.

We sourced information and vessel specifications for this article from sailboat manufacturers and record books. We also considered the opinions of sailors who own these vessels and sail them regularly.

Table of contents

What Makes a Sailboat Trailerable?

Trailerable sailboats must meet certain requirements in order to operate on American roads. The primary limitations are width (beam), as the vessel and its trailer must fit in regular traffic lanes and through tunnels. Another consideration is weight, as the vessel should be light enough to be towed by a 3/4 ton or 1-ton pickup truck.

Generally speaking, there's not a specific limit to boat weight in order to be towed. That said, most single and tandem-axle trailers can't exceed about 3,300 pounds per axle. With that in mind, the upper limit for a trailerable sailboat is around 7,000 to 8,000 pounds.

Keel type is an important factor to consider, as it determines how high off the ground the boat has to ride on the trailer. The majority of trailerable sailboats have a centerboard or swing keel that retracts for towing and beaching. Some vessels have shorter displacement keels or fin keels.

The maximum allowable for a trailerable sailboat is 8 ft 6 in. This is because these dimensions are the maximum limit for standard trailers on American roads. A larger boat can be transported on the road, but only as an oversize load.

In practice, very few trailerable sailboats have a beam of exactly 8 ft 6 in. The majority of large trailerable sailboats have a beam of between 7 1/2 ft and 8 ft 3 in. This makes it easier to negotiate tunnels and tighter traffic lanes.

Overall Length

The maximum trailer length for standard trailers is 65 ft, but it's nearly impossible for a trailerable sailboat of this length to meet the width requirements. In practice, the longest trailerable sailboats are around 30 ft in length or shorter. The average is about 20 to 25 ft.